4

Disassembly & Assessment

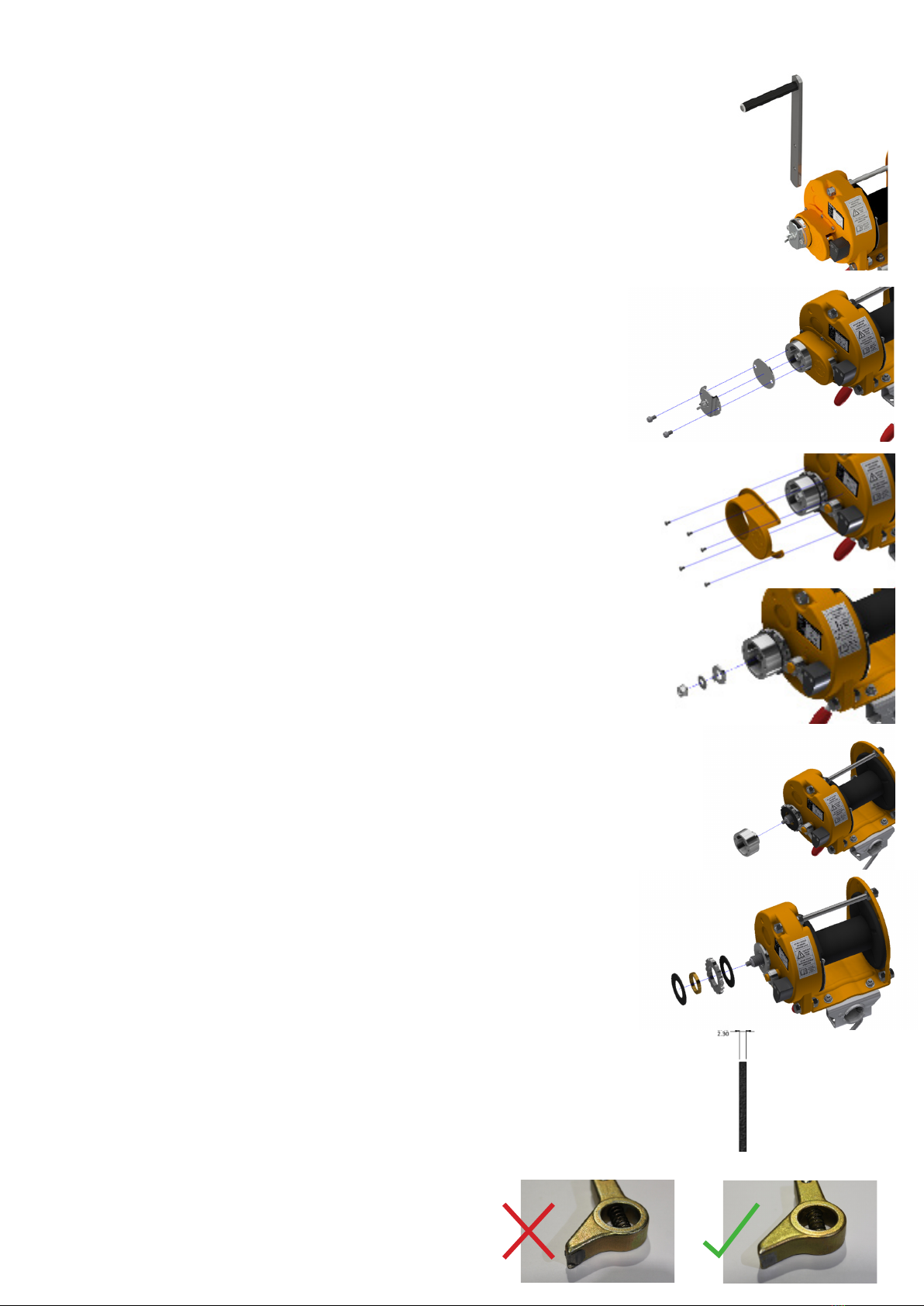

1. GENERAL CONDITION

It is important to ensure the winch is safe to handle before work

commences. Firstly, inspect the condition of the housing and the drum

ensuring all fasteners are present and secure.

Any G.Winch units that:

- Do not pass basic function test.

- The winch body / frame is out of alignment, bent or damaged.

- Require stripping down of the winch body.

Are beyond the scope of this manual. These units should be returned

to Globestock for repair work to be assessed and completed. The

bodyalignmentisdicultandincorrectalignmentmaycausea

release of the lifted load during use.

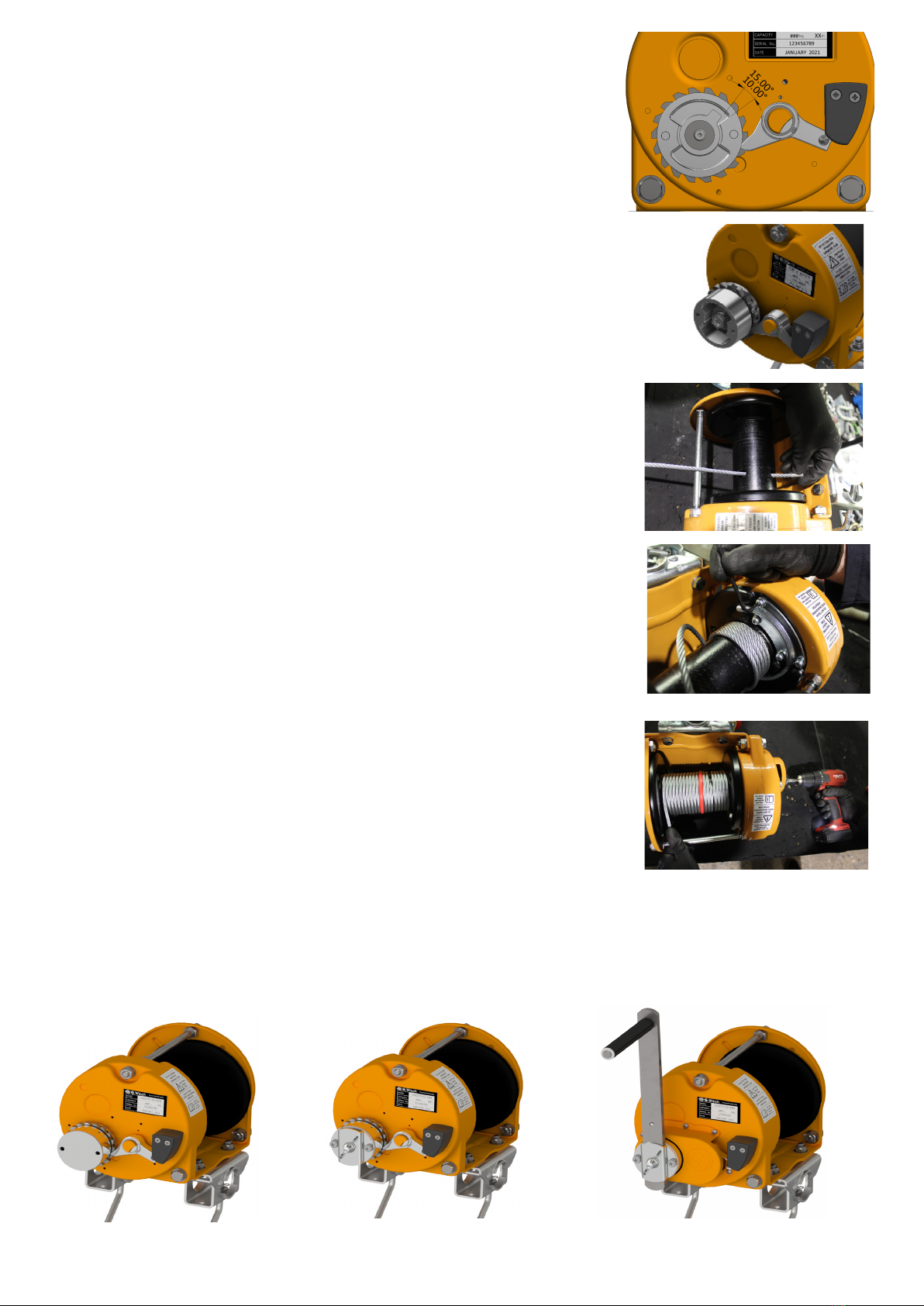

2. INSPECT IDENTITY LABEL

This can be found on the side of the housing. Take note of the wire

rope length, material and maximum working load. Make sure the

label is legible and fully attached. If there is any damage the label

must be replaced.

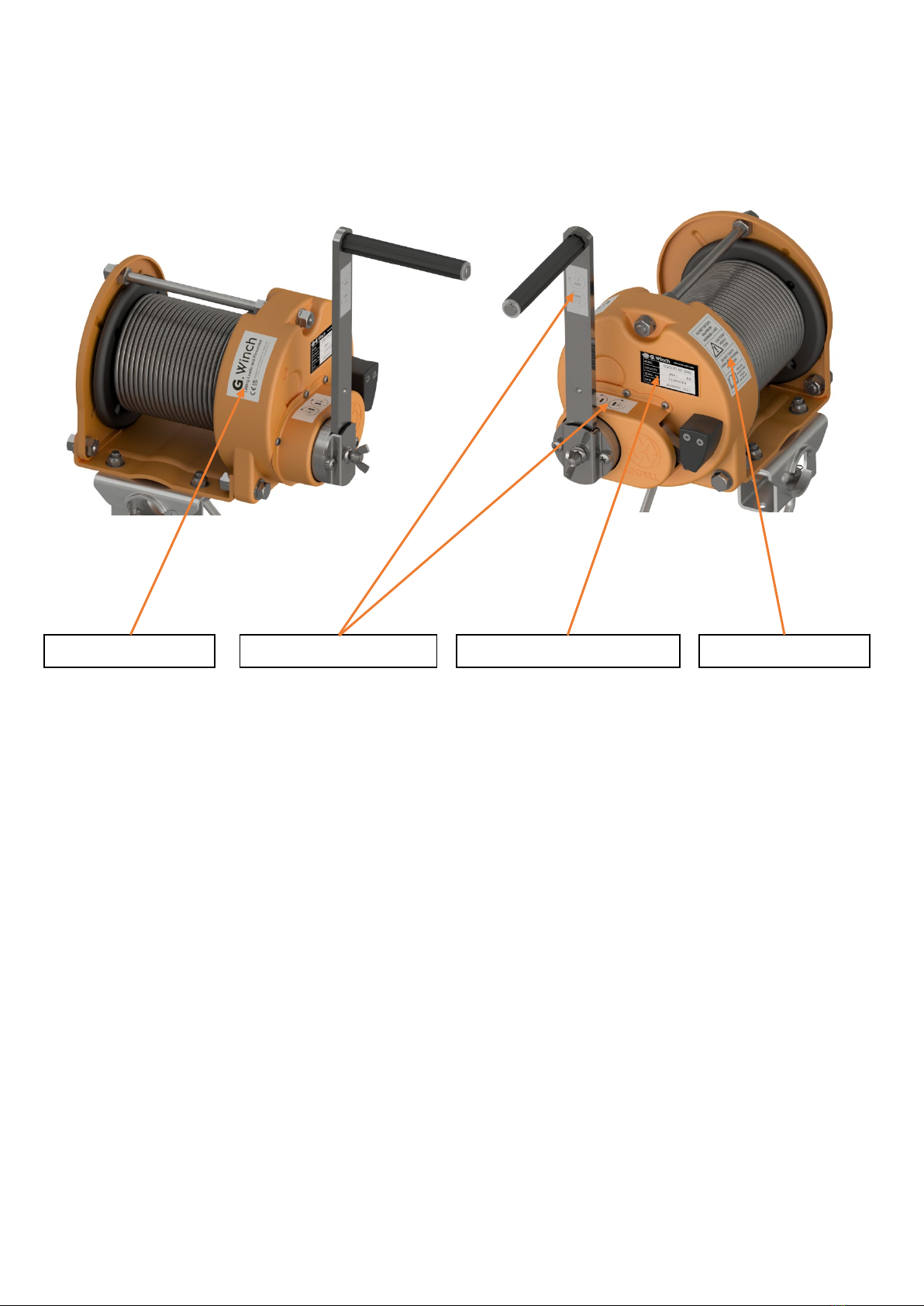

3. INSPECT ROPE & KARABINER

To extract the rope, the pawl mechanism must be disengaged and

held to allow the drum to free spool. This can be clamped into

place, or the pawl stop can be removed, and the pawl lever pushed

beyond the return point.

Ifthepawlstopisremoved,thismustbere-ttedbefore

completion.

Fully extract the wire rope inspecting for:

Corrosion Broken Wires Kinking Severe Wear Damaged Fittings