8 9

2. Warning Notes

●This machine is not suitable for removing dust that

presents a health hazard!

●This machine is only intended for wet cleaning of

non-textile floors!

●This machine is not approved for use on public paths

or roads!

●This machine may only be used by persons, who

have been instructed in and expressly familiarised

with its use!

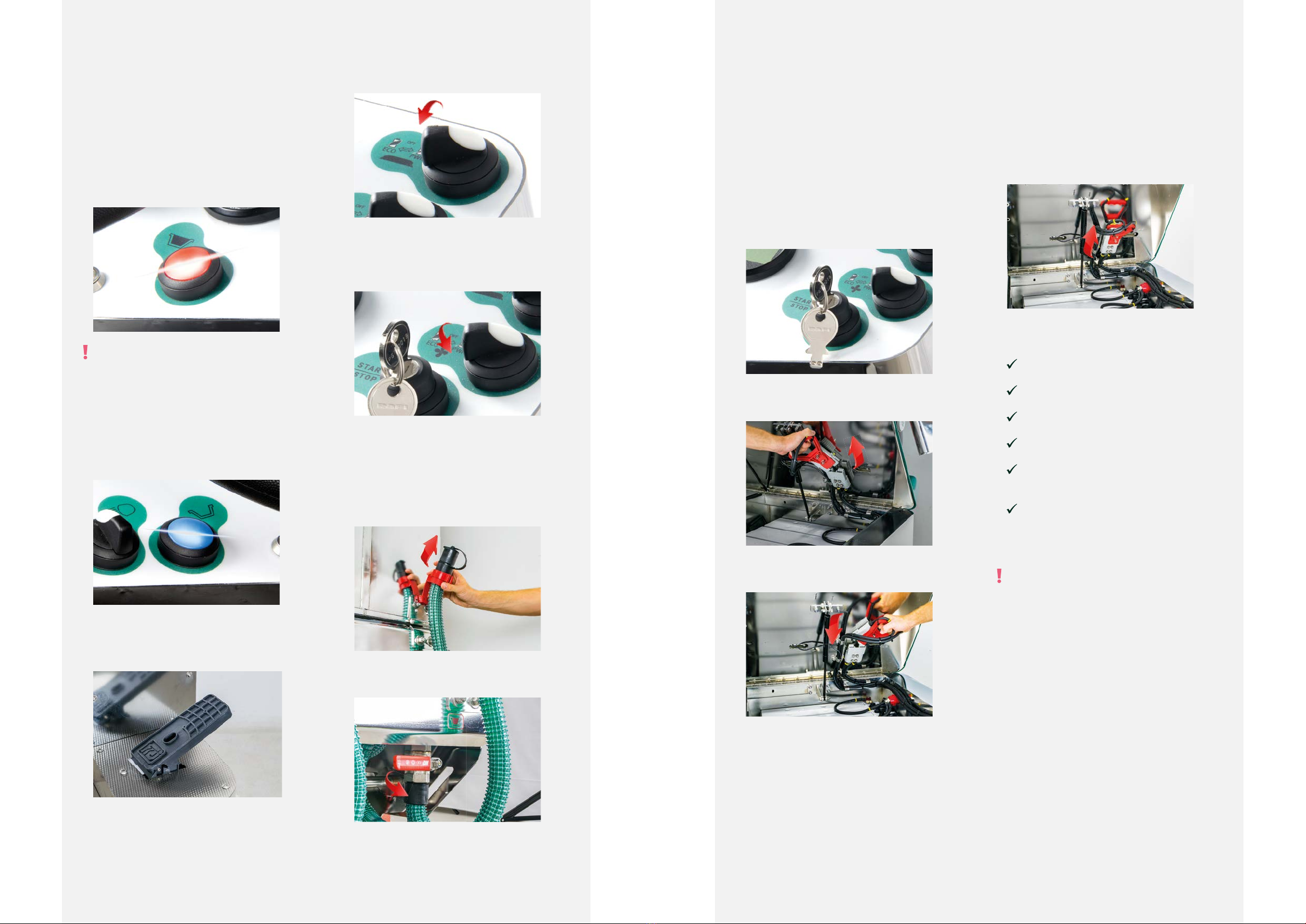

●To prevent unauthorised use, the key must always be

removed from the key switch [7] when leaving the

machine unattended!

●The machine must be secured against accidental

movements when left unattended by operating the

foot brake.

●Always watch for others, and in particular children,

when working with the machine!

●The machine is only approved for use on flat

surfaces up to a maximum inclination of 2%!

Note: The installation and / or the use of other

than Rotan™ original parts and accessories can

negatively change the design characteristics or

even impair the active and / or passive driving sa-

fety of your cleaning machine! The manufacturer

excludes any liability for damage caused by the

use of parts and accessories other than Rotan™!

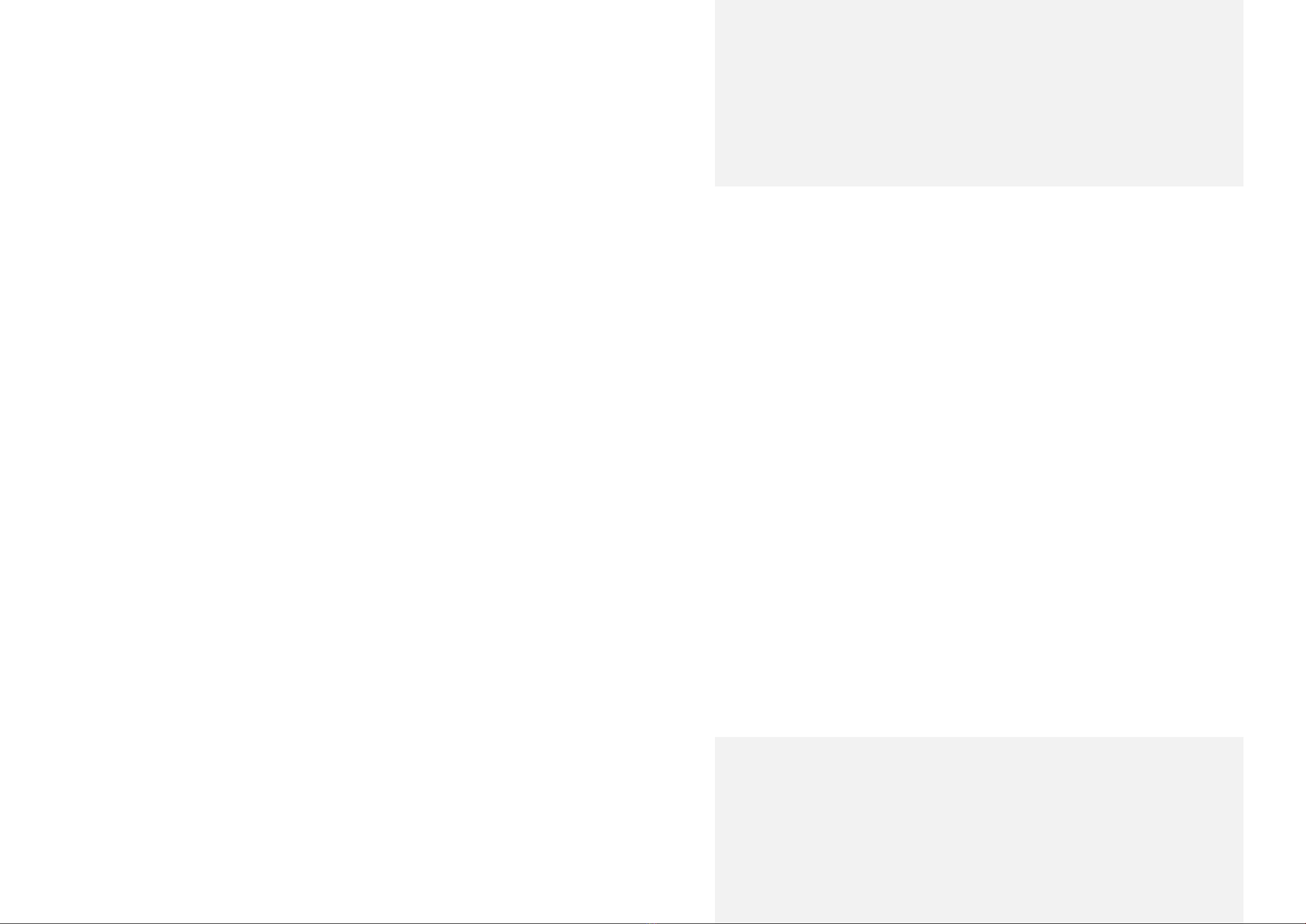

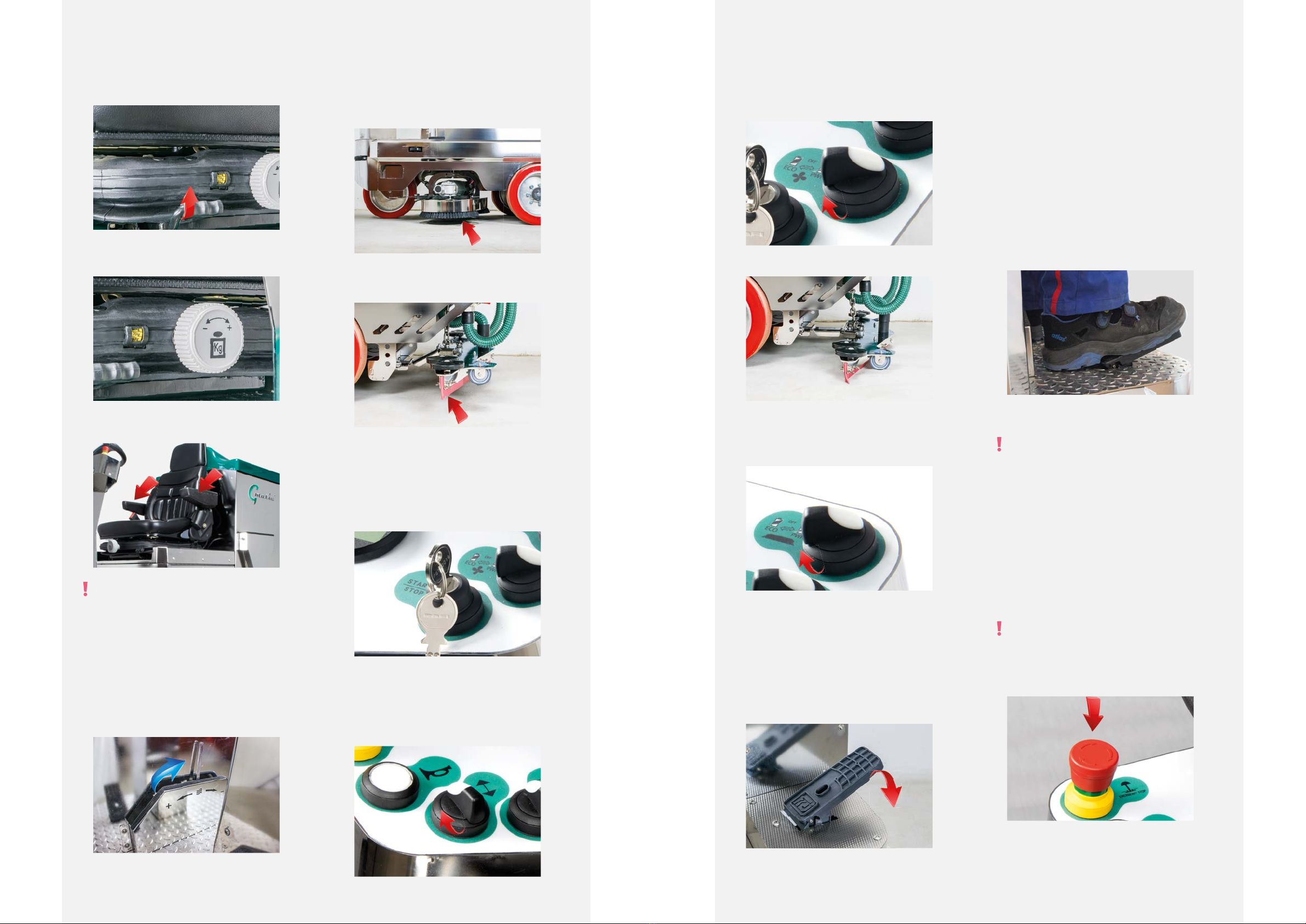

●When cleaning and performing maintenance on the

machine and when replacing parts:

-the red machine plug [25] must be removed from

the battery socket outlet [26] (on the back of the

machine)

-the key must be removed from the key switch [7].

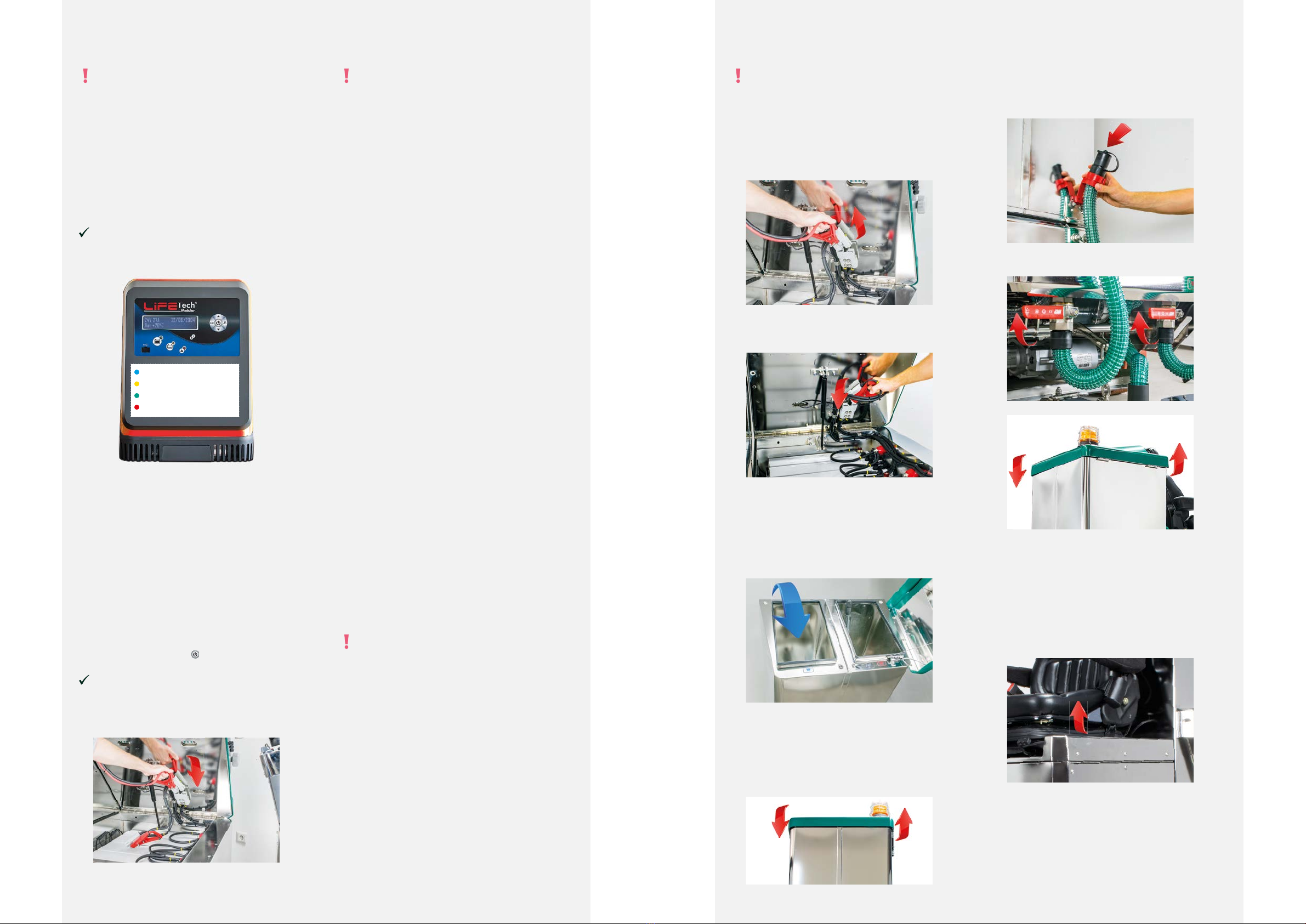

●Charging cables (connection cable from the charger

to the machine) must not be modified, in particular

not extended!

●Brand new batteries can not deliver the full power

yet, but only after activating the first 8 to 10 charging

or discharging cycles. Therefore do not use the

machine for an over-extended period of time.

●Never cover the top lid [13] with heavy objects for an

extended period of time (to protect the sealings, as

well as to avoid warping)!

●Before using the batteries, read the enclosed

documents:

-Operating instructions for the batteries

(see 4. Batteries).

-Operating instructions for the charger

(see 3. Charger)

2.1 Wet Batteries:

Note: Always pay attention to the use of supplied

wet batteries (does not apply to maintenance-free

batteries):

-Battery gases from wet batteries are highly

explosive! Avoid sparking and open flames

near the battery!

-Good air circulation must be ensured in

rooms in which wet batteries are charged!

-To avoid gas formation during the charging

process of the batteries, please note: Always

keep the water tanks folded up as far as they

will go!

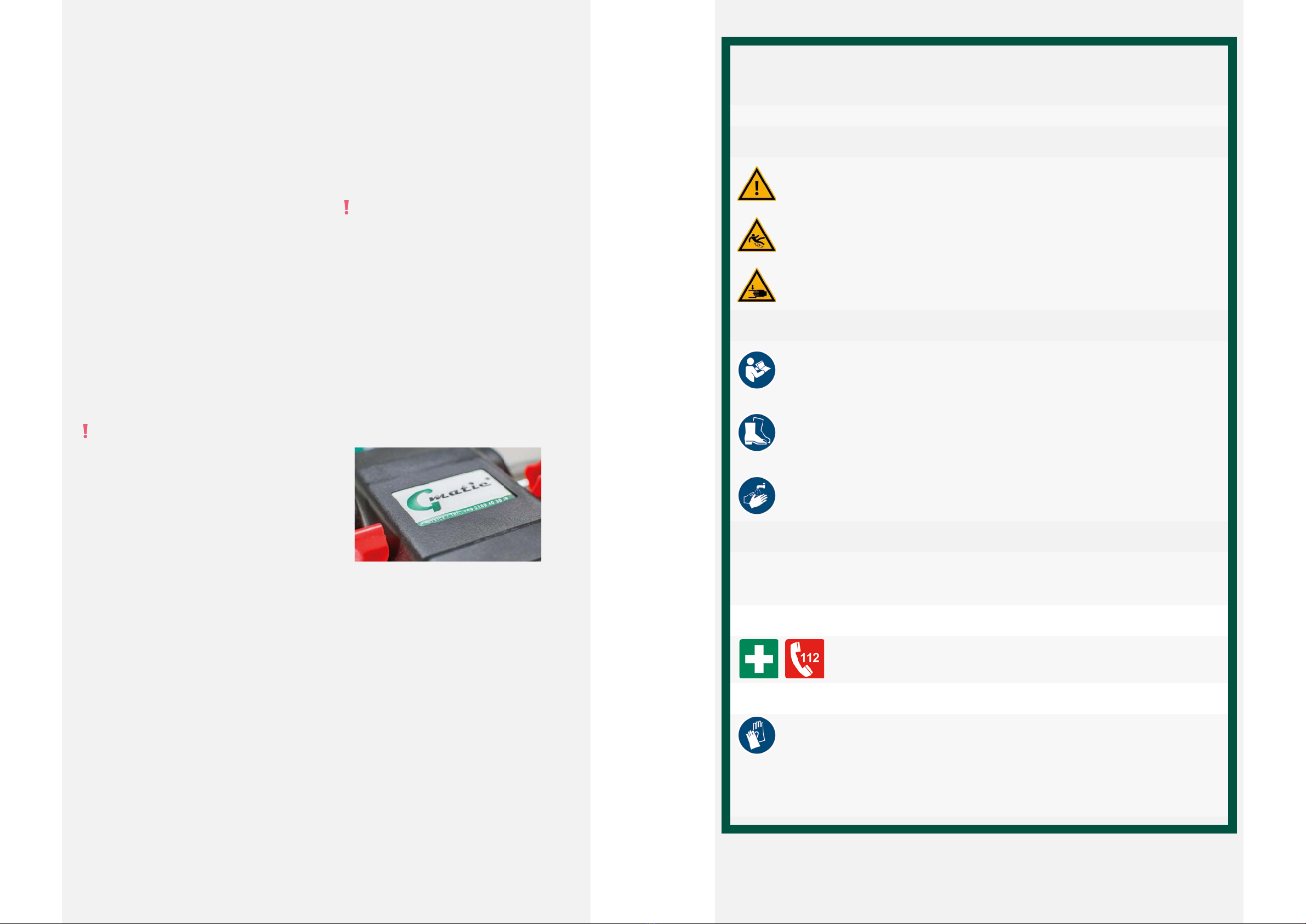

2.2 questions and answers

Tel. +49 2389 40 30 20

AS OF

08/2020 OPERATING INSTRUCTIONS

Scope of application

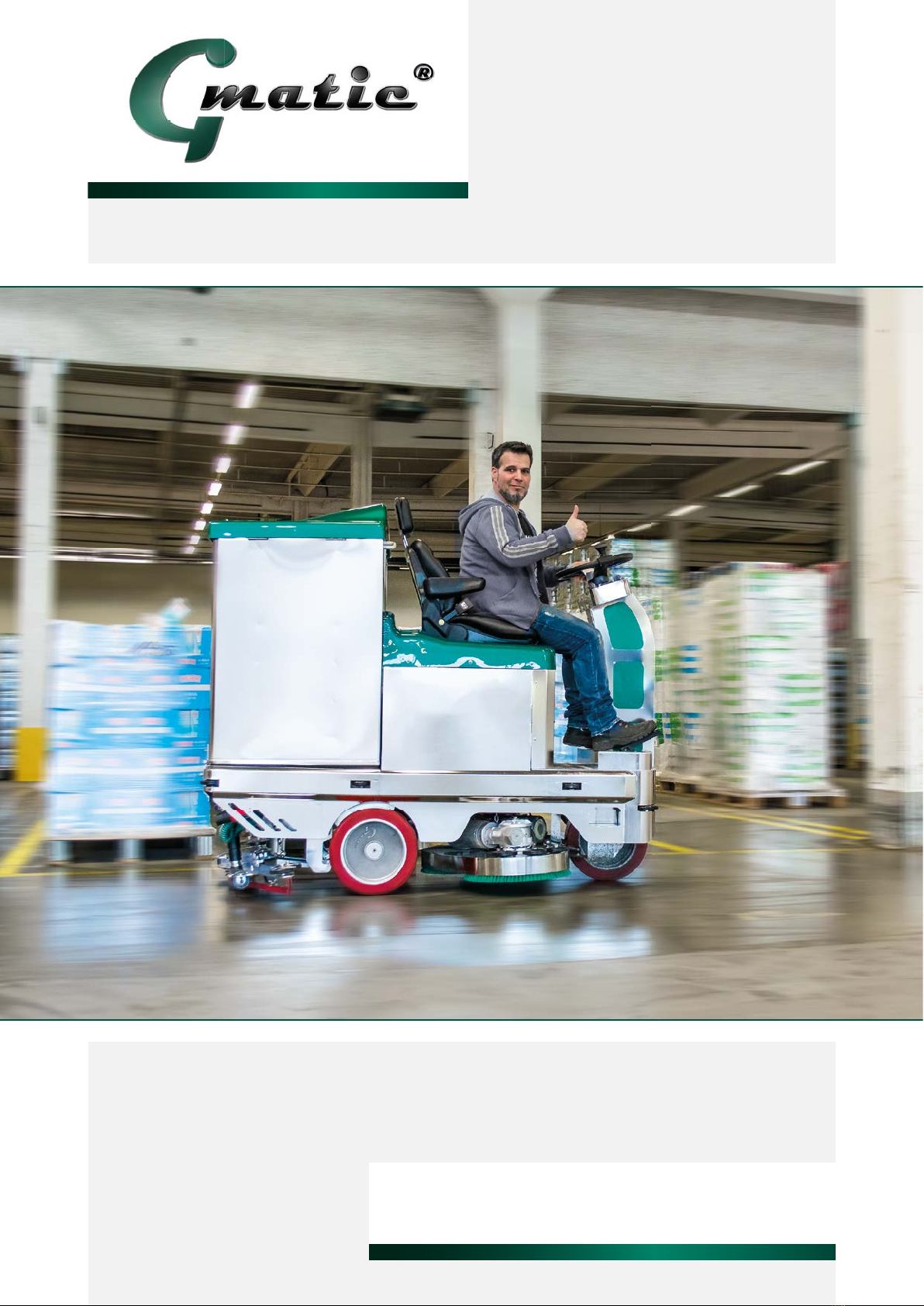

Gmatic®scrubber drier (ride-on)

Dangers for humans and the envirnoment

Injuries caused by collision with people and damage to objects.

Fall injuries. In the event of irregular and / or improper maintenance, there is a risk of injury from residual

moisture behind the squeegee.

Crash Injuries. Do not use the scrubber drier on the ramp table and keep a safety distance of 30cm to pre-

vent people and machines from falling down.

Hand injuries due to pinching or crushing. If the water tank has been folded up for emptying, there is a risk

of injury by folding or squeezing your fingers between the tank and the machine chassis while folding back

into the starting position.

Protective measures and rules of conduct

Use only by trained personnel. Observe the manufacturer‘s operating instructions.

Wear sturdy shoes.

For hygienic reasons, wash hands before and after use.

Do not park the scrubber drier on escape routes or in front of emergency exits.

Park securely against rolling away. In the case of machines without a parking brake, the brush head must

be lowered for safety.

The tank is only emptied into a designated floor drain and not over the ramp table into the outside area.

Response to malfunctions

When detecting malfunctions, do not use the scrubber drier and secure it against any further use. Remove

the key and do not leave it to unauthorized persons. Pull the machine plug. Inform responsible persons. Call

hotline if you have any questions: 02389 403020

First aid

Keep Calm. Consult first aider. CALL EMERGENCY: 112

Inform those responsible. To report an accident.

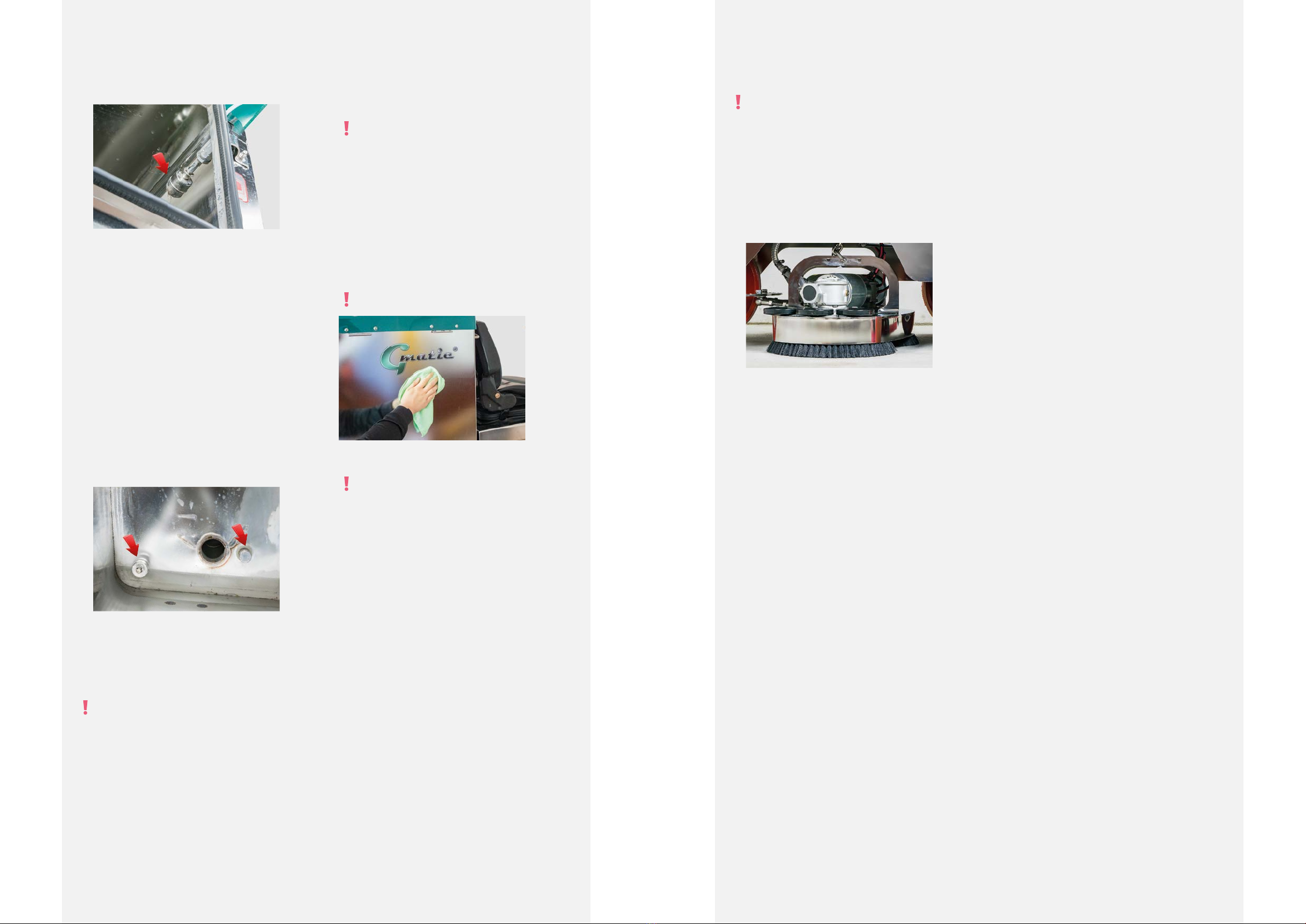

Serving and maintenance

Servicing and maintenance only by trained personnel or a specialist company. Work gloves must be worn

during maintenance work (especially changing brushes).

After each use: Empty the dirty water tank and rinse it thoroughly (including the float switch). Remove

blockages in suction and drain hoses. Clean the underside of the squeegee. If the suction power drops,

the suction lips must be turned. Wear parts such as tank seals, suction lips, hoses and brushes must be

requested in the workshop in good time.