GMP Breeze 89010 Troubleshooting guide

Page 1 of 42 General Machine Products (KT), LLC

89010 (BREEZE) – USA

CABLE BLOWING MACHINE

Copyright 2017 by General Machine Products (KT), LLC

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of General Machine Products (KT), LLC

BREEZE MICRO CABLE BLOWING MACHINE

OPERATION & MAINTENANCE

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

September 18, 2017 USA Ver 14a

QC Final Inspection by:_________________________ Date:__________________

Unit Serial Number:__________________

Build Date:__________________

Manual Part Number 32384

Page 2 of 42 General Machine Products (KT), LLC

Rel.no Date Details Author

01 08.27.03 Original issue A. Sibun

02 09.19.07 US Version 1 A. Konschak

REVISION HISTORY

03 07.05.07 US Version 2 A. Konschak

04 04.30.08 US Version 3 A. Konschak

05 05.25.09 US Version 4 A. Konschak

06 11.23.09 US Version 5 - updated CUB5 Matrix A Konschak

07 06.09.10 US Version 6 - update Appendix 1 A Konschak

08 03.29.11 US Version 7 - update blown fiber page 24 A Konschak

09 05.18.11 US Version 8 - add guide positioning warning A Konschak

10 10.03.12 US Version 9 - add 14 mm tube kit A Konschak

11 06.23.13 US Version 10 - A Konschak

12 12.18.13 US Version 11 - Various minor updates A Konschak

13 07.23.15 US Version 12 - Photo updates A Konschak

14 10.20.16 US Version 13 - Part number updates A Konschak

15 06.29.17 US Version 14 - Added 14mm to configuration A Konschak

15a 07.17.17 US Version 14a - Changed the company name A Konschak

GMP Limited Warranty can be found at http://www.gmptools.com/warranty/

Page 3 of 42 General Machine Products (KT), LLC

CONTENTS

1. Safety Instructions

2. Critical Points

3. General Description

4. Specification

5. Operating procedures

6. Maintenance

7. Procedure for changing inserts in the tube clamp

8. Procedure for changing inserts in the air box

9. Procedure for changing inserts in the infeed guide

10. Procedure for re-positioning the measuring system fixed roller

11. Procedure for replacing the air box housing seal

12. Procedure for changing the air box infeed guide

13. Procedure for changing the drive rollers

14. Procedure for conversion to blow 12 count (1.6) fiber

15. Monthly Service – check list

16. Service History Record

17. Tube integrity and Lubrication

18. Recommended Spares List

APPENDICES

Appendix 1 Cable and tube insert selection chart.

Appendix 2 Recommended torque control potentiometer settings

Appendix 3 Programming the speed/distance measuring device.

GMP Limited Warranty

Page 4 of 42 General Machine Products (KT), LLC

1. SAFETY INSTRUCTIONS

WORK AREA AND GENERAL SAFETY

1. Read and understand the operation and maintenance manual supplied with this equip-

ment. Keep it in a convenient place for future reference.

2. Keep children and untrained personnel away from this equipment while in operation.

3. Keep all guards and safety devices in place. Do not operate this equipment with guards

removed or damaged.

4. Keep hands, feet and loose clothing away from moving parts, especially at cable entry

points.

5. Always stop the machine and isolate compressed air and electrical services to carry out

lubrication and servicing.

6. Check machine before starting for worn or damaged parts. Check for signs of loose nuts

and bolts etc.

7. If machine is left unattended, insure that unauthorized use is prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public places, observe all

statutory requirements for working environments.

10. Beware of pinch points involved with rotating components.

11. Beware of hot surfaces, machine uses compressed air.

12. When operating machine always wear appropriate safety clothing, hearing protection, eye

protection, hard hat, safety shoes and leather gloves, machine operates with compressed

air at up to 218 psi.

13. Prior to installation insure the tube route is connected properly.

14. Beware of exposed electrical contacts. Do not touch, or allow metal objects to come into

contact.

15. Machine may cause additional fire hazard if involved in an existing fire due to com-

pressed air.

This Equipment should be used only by personnel who have been given the appropri-

ate training and who are competent to use it.

These instructions are to be made available to operators of this equipment at all times.

Failure to observe these safety instructions could result in serious personal injury and/

or property damage.

Page 5 of 42 General Machine Products (KT), LLC

16. No personnel are to be in manholes or ducts when the Cable Blowing Machine is being

operated.

17. The machine must be operated on firm ground.

18. Stay clear of cables or lines under tension.

19. Stay clear of pressurized air line and tube.

20. Only use the machine for its intended purpose. Do not use the roller drive without the air

chamber to push or to retrieve cable or blow air in the far end of tube to help cable

recovery.

21. Do not place cable drum too close to the Cable Blowing Machine.

22. Do not tamper with pressure relief valves or pressure reducing valves.

23. The compressed air supply must not be allowed to enter the air chamber or tube before

the drive rollers have been closed on to the cable. Do not turn the air on until a reasonable

length of cable (165 ft) has been installed into the tube.

24. Ensure the cable drum rotates freely on its stand, the cable should leave from the top of

the drum.

25. The cable should enter the machine in a clean and dry condition. In damp, dusty atmos-

pheres, the cable should be cleaned continuously as it enters the machine.

FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY, AS THE CABLE

COULD BE EJECTED FROM THE CABLE BLOWING MACHINE WITH HIGH

FORCE AND VELOCITY.

Page 6 of 42 General Machine Products (KT), LLC

GENERAL PNEUMATIC SAFETY INSTRUCTIONS

The GMP Fiber Optical Cable Blowing Machine is a pneumatic device, using pressurized air

to project cable at high velocities. Please observe the following precautions when operating

the Cable Blowing Machine:

1. Compressed air can cause flying debris. This could cause personal injury. Always wear

personal protective equipment.

2. Insure no personnel are in the manhole at the far end of the cable run. Severe personal

injury may result.

3. Never open the air chamber when pressurized.

4. Only authorized, fully trained personnel should operate the air compressor.

GENERAL ELECTRICAL SAFETY INSTRUCTIONS

The machine has electronic and electrical power and control circuits. Electric shock hazards

exist that could result in severe personal injury. Observe the following precautions to avoid

electrical hazards:

1. Do not operate in water.

2. Do not expose the machine to rain.

3. Do not remove cover of electronic control assembly. There are no user serviceable parts

inside.

4. Refer servicing to qualified service personnel.

Page 7 of 42 General Machine Products (KT), LLC

2. Critical points that dramatically affect the operation of the cable blowing

machine.

Pressure on the cable (Position of the close arm assy) should be set as per the instruc-

tions.

Rollers to be closed at all times when cable is installed into machine.

Cord seals in air chamber correctly fitted to provide good sealing.

Correct cable seal fitted.

Tube fully connected and pressure-tested.

Tube connecting fittings are suitable for operating at 220 PSI air pressure.

Tube clamp securely tightened.

Compressor capacity 220 PSI and suitable for size of tube being used.

Cable drum must be located directly behind and in line with the blowing machine.

Air chamber, drive rollers, cable guides, must be clean and free from debris, sludge, dirt,

water and lubricant.

The cable must be hand guided into the blowing machine through a dry clean cloth by the

operator wearing work gloves.

Ensure the compressed air supply is not applied to the cable until approximately 165 ft of

cable have been installed or the motor begins to labor.

Page 8 of 42 General Machine Products (KT), LLC

DISCLAIMER

General Machine Products (KT), LLC and CBS Products Ltd. takes care in the design of its

products to insure that the cable is protected during installation. Due to the variety and differ-

ent methods of cable manufacture the responsibility of checking the cable compatibility with

the equipment lies with the user. Therefore, GMP nor CBS Products Ltd. can accept liability

for any damage to the cable.

Page 9 of 42 General Machine Products (KT), LLC

3. GENERAL DESCRIPTION

The Breeze Micro Cable Blowing Machine is designed to install small diameter cable into

micro tubes.

The Breeze uses a DC motor and reduction gearing to

drive a pair of compliant rollers that are both driven.

The rollers are covered with a soft synthetic coating to

prevent damage to the cable. Different coatings are

available depending on the surface texture of the cable

being installed. The rollers may be changed quickly us-

ing one simple tool.

The pressure the rollers apply to the cable is adjusta-

ble.

The torque applied to the cable by the rollers can be

adjusted to help prevent cable buckling.

A full range of accessories is available to allow the ma-

chine to handle a wide range of cables and micro tubes.

As pictured, the Breeze may be placed on the ground or on a support to bring the cable to a

suitable height. The Breeze is supplied with a

reinforced case which will protect the machine

from damage during transit and can also be used

as a support for the machine when installing ca-

ble.

Page 10 of 42 General Machine Products (KT), LLC

4. SPECIFICATIONS

Cable size: 1.0 to 8.5 mm1 0.1” to 0.335”

Tube size: (OD) 4 to 18 mm 0.158” to 0.709”

Cable speed: 0-50m/min. 0-165 ft/min

Maximum pushing force: 16 Kg. 35 lbs.

Maximum air pressure: 15 bar. 220 psi.

Power requirements: 115/220V ac 50/60 Hz

Switchable

Gripping force, (rollers onto cable): 1-40 Kg 1-88 lb.

Weight 23Kg approx. 50 lbs. approx.

Dimensions (ht x length x width) 250mm x 390mm x 270mm 10” x 15 3/8” x 10 5/8”

1 1 - 2.5 mm blown fiber available with add-on kit

Page 11 of 42 General Machine Products (KT), LLC

5. OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING THIS

CABLE BLOWING MACHINE:

● HAVE RECEIVED COMPREHENSIVE TRAINING IN THE USE OF THIS MACHINE.

● ARE COMPETENT AND AUTHORIZED TO USE IT AND HAVE READ AND UNDER-

STAND THIS MANUAL.

GENERAL MACHINE PRODUCTS (KT), LLC OR CBS PRODUCTS LTD. CANNOT BE

HELD RESPONSIBLE FOR MISUSE OF THIS EQUIPMENT.

Set up for installing cable with the machine mounted above ground:

1. Position the machine in line with the route of the duct.

2. Position the cable drum behind the machine and in line with the machine.

See sketch below (this shows a plan view of the recommended set up).

3. Ensure the machine is secure (either on its own stand or a separate suitable stand).

4. Ensure the machine is fitted with the appropriate guides and collets to suit the cable being

installed and the tubes into which the cable is to be installed. (See appendix 1 for details

of interchangeable parts).

To set the machine up to install cable it will be necessary to:

1. Fit the tube into which the cable is to be installed into the tube clamp and air box .

2. Fit the cable through the machine.

3. Connect the air supply to the machine.

4. Connect the electrical power input to the machine.

Cable Drum Breeze Machine

Tube route

Page 12 of 42 General Machine Products (KT), LLC

Fit the tube into which the cable is to be installed into the air box and tube

clamp.

Slide a tube seal, sized for the

tubing you are using, over the end

of the tube.

Fit the tube about half way into

the air box housing as shown in

the photo, positioning the tube

seal so that it sits against the seal

face.

Positioning the tube further into

the air box helps prevent the buck-

ing of smaller fiber.

Once the tube has been posi-

tioned, the tube clamp may be

closed. Securely tighten clamp

with swing bolt. The tube is now

secure.

Cut and split a short length of tube to use as

an in-feed guide (this tube need only be split if

blowing a cable mid-span; sometimes called

series blowing). This should be inserted in the

in-feed guide clamp. (In order to give the best

support for the incoming cable, it may be help-

ful if the end of the tube is cut off at an angle

to match the angle on the in-feed guide

clamp. This short length of tube will act as a

guide to feed the incoming cable into the

measuring system and into the in-feed guide.

If necessary a length of smaller diameter tube

may be fitted inside this tube to act as a guide

for smaller diameter cables.

Page 13 of 42 General Machine Products (KT), LLC

Fit the cable through the machine.

Hold back the measuring

wheel, so that the spring is

compressed.

Raise the clear cover to

expose the roller drive.

Loosen the thumb nuts and re-

tract the cable guide top plate.

Loosen the thumb

nut and open the

seal housing.

Move the drive roller close

assembly to the far right to

fully open the rollers.

It is now possible to insert the cable in the machine.

Pass the cable through the tube in the in-feed guide clamp, on through the in-feed guide as-

sembly and through the gap between the drive rollers. Place the cable in the groove in the ca-

ble guide set. Select the appropriate split cable seal (see appendix 1) and position it around

the cable. Press the cable seal into the groove in the seal housing, simultaneously placing the

cable in the seal guide half and insert the cable in the tube entry.

The cable is now positioned in the machine.

Measuring

Wheel

In-feed

Guide

Clamp

In-feed

Guide

Assembly

Page 14 of 42 General Machine Products (KT), LLC

a. Close the air box.

b. Close the cable guide set top cover.

c. Release the measuring wheel and allow it to rest on the cable.

d. Close the transparent cover. (note: This cover must be closed in order for the machine to

operate)

Close the drive roller assembly onto the cable as follows:

The photo shows the drive roller close thumb nut slightly loosened. (The assembly is free to

move).

This thumb nut is fixed to the clamp arm lever.

The clamp arm lever controls the position of the roller

assembly.

As the clamp arm is moved to the left, the rollers

move together. When the clamp arm is furthest to the

right, the gap between the rollers is at its widest. Once

the cable has been positioned in the machine the roll-

ers must be closed on the cable in order to drive the

cable. (And to stop the cable being dragged back out

of the machine by any tension in the cable).

Split cable seal

(see appendix 1)

Seal Guide Half

Cable Guide Set top

cover

Page 15 of 42 General Machine Products (KT), LLC

The amount of pressure on the cable can be varied simply by loosening the thumb nut, mov-

ing the clamp arm lever to the right or left; as required, and tightening the thumb nut.

As more experience is gained using the machine, the amount of compression required will

become clear. Note: An alternative method of setting the compression force is detailed in the

note at the end of appendix 2.

Connect the air supply to the machine.

Supplied with the

Breeze is a rein-

forced braided

supply line with a

300 psi pressure

gauge, ball type

shut off valve and

a quick discon-

nect female cou-

pling for connect-

ing to the ma-

chine. A 1/2” twist

-lock claw hose

coupling is provided to connect to your compres-

Connect the electrical supply to the machine.

The machine is supplied complete with an electrical

supply lead and a NEMA 5-15 plug.

The machine is now ready to start the cable installation.

The Breeze is designed to operate with either 115 volts or 220 volts AC. The default setting

for the Americas is 115 volts. To change the voltage setting, locate the voltage switch under

the silver plug located to the left of the fuses. Looking into the hole with a flashlight, position

the switch to the desired voltage.

Brown (Live)

Yellow & Green

(Earth)

Blue (Neutral)

If the connecting plug on the power lead to the gen-

erator/ (or supply) supplied with the Breeze machine

is unsuitable and requires replacement, the new

plug must be correctly connected observing the col-

or codes as shown below.

It is the responsibility of the user to

ensure that the connections meet

the electrical regulations for the rel-

evant country.

The air inlet to the machine is male

fitting for a quick release coupling.

Page 16 of 42 General Machine Products (KT), LLC

Set up for installing cable with the machine mounted below ground:

The set up is similar to the set up for installing cable above ground, (described previously)

typically this type of installation is demanded for “series blowing” i.e. when a length of cable is

already installed, and the limit of installation distance is reached. In such cases it is customary

to couple a “series machine” sited down a manhole some distance from the point of main in-

stallation. This machine operates in conjunction with the machine sited at the main point of

installation. The GMP Breeze machine is ideally suited to this type of operation, it may be

coupled with a second machine to increase the distance a single cable can be installed with-

out splices. The only difference between this set up, and the set up for installing cable with

the machine above ground, is that there will be no drum stand carrying the cable drum. The

cable will be exiting from one side of the manhole and blown into the tube at the other side of

the manhole. The machine should be aligned with both the incoming cable and the outgoing

tube path, both side to side and up and down.

NOTE: THE MACHINE MUST NOT BE SUBMERGED IN WATER.

If the hole is full of water it must be pumped out before placing the machine on the bottom of

the hole.

Page 17 of 42 General Machine Products (KT), LLC

Installing cable.

The machine is fitted with a range of controls to help the operator to install cable in the mini-

mum time with the least risk of causing damage to the cable or tube.

These controls are identified and their function is described below.

Torque control:

This knob controls the motor torque, turn this clockwise to increase the torque (pushing force)

applied to the cable by the rollers. Turn counter clockwise to reduce the amount of torque

(pushing force) applied to the cable by the rollers.

Torque Range Switch:

Switches between “normal” torque range for blowing micro fiber cables and “low” torque

range for finer torque adjustment when installing 1-1.6 mm “blown fiber”.

Speed control:

This knob controls the motor speed, turn this clockwise to increase the speed of the rollers

(and the cable). Turn counter clockwise to reduce the speed.

Emergency stop:

Pushing this red knob downwards will stop the rollers feeding the cable. This knob may be

used to switch the machine off, whether or not there is a need to stop in an emergency. To

release, twist the red knob counter-clockwise.

Torque Control

Speed/Distance

Indicator

Speed Control Emergency Stop

Start

Torque Range

Switch

Page 18 of 42 General Machine Products (KT), LLC

Start:

This switch “arms” the emergency stop circuit. If the emergency stop button is used to stop

the machine (whether in an emergency or not) it will be necessary to depress this switch be-

fore the machine will run again. Whenever the power to the machine is disconnected and re-

connected, it will be necessary to depress this switch before the machine will run.

Speed/Distance indicator:

This device will measure and display the distance traveled by the cable and also the speed at

which the cable is traveling. The functions are controlled by the small push button on the right

of the display. If this button is depressed, the display will “toggle” between speed and dis-

tance. If held down for more than three seconds, the display will reset to zero. Before starting

an installation, it will be necessary to depress the button for more than three seconds to set

the distance display to zero. Should it be necessary to replace the speed distance measuring

indicator, it will be necessary to reprogram it. See appendix 3

To install cable:

For the first time installing a cable type that has not been installed before and whose charac-

teristics are unknown.

1. Connect the power to the machine. The power supply should be nominally 115 volts single

phase AC 50 or 60 Hz. This may be derived from an IC engine driven generator, domestic

or industrial electrical supply. The power source should be fitted with a suitable connector,

see “Connect the electrical supply to the machine”. Page 15 of this manual.

2. Turn the torque control knob left, to the maximum counter clockwise position.

3. Turn the speed control knob to a position midway (11:00) between the maximum counter

clockwise and maximum clockwise position.

4. Press “start” button.

The machine will try to push the cable, with the torque control set to a minimum the rollers will

not turn or only very slowly.

It is now necessary to set the torque control to a position appropriate to the stiffness of the

cable and the characteristics of the cable insulation. See appendix 2 for recommendations. If

the cable type has been installed before, the settings will be available, the torque control knob

may be set at the previously determined position.

Set the torque control knob to the position determined above. The rollers will now start to turn,

and the cable will feed through the air box. When the cable has traveled a reasonable dis-

tance, (approximately 165 feet) turn on the air, this will help the machine to feed the cable.

The tube route through which the cable is to be fed, should be configured in such a way that

the cable can feed all the way along the tube and out the other end. It will be necessary to be

able to determine when the cable has emerged at the other end of the tube route. A typical

way of achieving this aim is to have a colleague positioned at the end of the tube run, in con-

tact with the main installer using a radio. In this way the main installer will be advised when

the cable has completed the run, so he can then stop the machine.

If there is an unexpected obstruction in the tube route, the rollers will see this as an increase

in torque demand, assuming the torque control has been set at an appropriate level. The roll-

ers will stop turning before they push the cable so hard as to cause it to buckle. If (due to lack

of previous knowledge of the cable characteristics) the torque control has been set at a figure

which is too small to push the cable, the setting may be increased. Bear in mind that this will

increase the risk of the cable being damaged by buckling.

Page 19 of 42 General Machine Products (KT), LLC

6. Maintenance

The Cable Blowing Machine has been designed to give reliable, trouble free service over long

periods. The machine requires no sophisticated maintenance procedures, simple common

sense checks and precautions are all that are needed.

The main source of breakdown and/or malfunction of a machine being used outdoors is con-

tamination by the elements, this contamination may be introduced into the machine in a num-

ber of different ways.

There may be mud, dust or other contaminants carried into the machine on the cable or tube

(there may be surface coatings of lubricants or other release type agents on the outer surfac-

es of the cable and tube, this could build up on the rollers and make them slip).

The machine may be set down on a muddy surface, or be splashed by vehicles when it is be-

ing used by the roadside.

* M.E.K. (methyl ethyl ketone) is a solvent; the safety precautions outlined on the document

supplied with the chemical must be observed.

Infeed guide assy:

this should be kept

clean. Build up of dirt

etc on the faces will

cause the cable to

catch on the guide.

Clean with any work-

shop solvent. Pay

particular attention to

the joint faces of the

inserts and the hous-

ing.

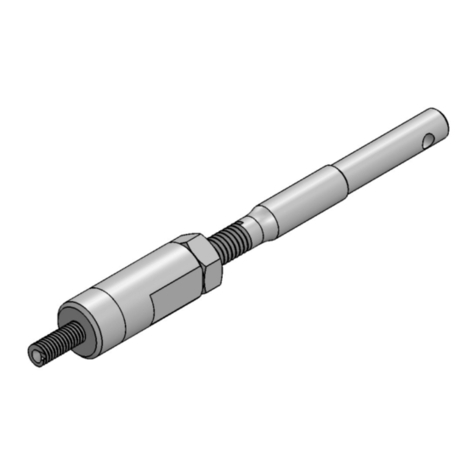

Measuring system fixed roller: this should be kept clean. Build up of dirt etc on the faces

will cause faulty readings of speed and/or distance. Clean with warm soapy water, wash off

and allow to dry. For stubborn marks and build up M.E.K* may be used.

Drive rollers: these should be kept clean.

Build up of dirt etc on the faces will cause

slip and/or jerky feeding of the cable.

Clean with warm soapy water, wash off

and allow to dry. For stubborn marks and

build up M.E.K* may be used.

Measuring roller: this should be kept clean.

Build up of dirt etc on the faces will cause

faulty readings of speed and/or distance.

Clean with warm soapy water, wash off and

allow to dry. For stubborn marks and build up

M.E.K* may be used.

In-feed Guide

Clamp: this should

be kept clean. Build

up of dirt etc on the

faces will cause the

cable to catch on

the guide. Clean

with any workshop

solvent.

Page 20 of 42 General Machine Products (KT), LLC

The machine should be returned to the General Machine Products Co,, Inc., Trevose, Pa.

after every 1000 hours use (or at intervals of 12 months) for a major service.

As a general rule, every time an interchangeable part is removed and replaced by a part of a

different size, shape etc. the part being removed should be thoroughly cleaned before being

returned to its box. Similarly the cavity from which it was removed can also be cleaned prior to

the assembly of the replacement part.

Air box parts: Keep clean. A build

up of moisture and dust will pre-

vent the joint faces from mating,

preventing the housing seal from

sealing. Use any traditional work-

shop cleaning agent.

Tube clamp inserts:

Keep clean. A build up of

moisture and dust, partic-

ularly in the grooves, will

reduce the clamping ef-

fect. Use any traditional

workshop cleaning agent.

Cable guide set parts: Keep clean. A

build up of moisture and dust may catch

the cable. This could cause the machine

to stop feeding. Loosen the thumb nuts

and slide back the top plate to expose the

guide groove. Use any traditional work-

shop cleaning agent.

Table of contents

Other GMP Power Tools manuals