GMP ACCELAIR 2 User manual

Copyright 2021 by General Machine Products (KT), LLC

All rights reserved. No part of this publication may be copied,

reproduced or transmitted in any form whatsoever without the

written permission of General Machine Products (KT), LLC

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • www.gmptools.com

February 15, 2021 USA ver 04H

Manual P/N 34061

ACCELAIR 2 BLOWN FIBER MACHINE

P/N 89500

OPERATION AND MAINTENANCE MANUAL

2

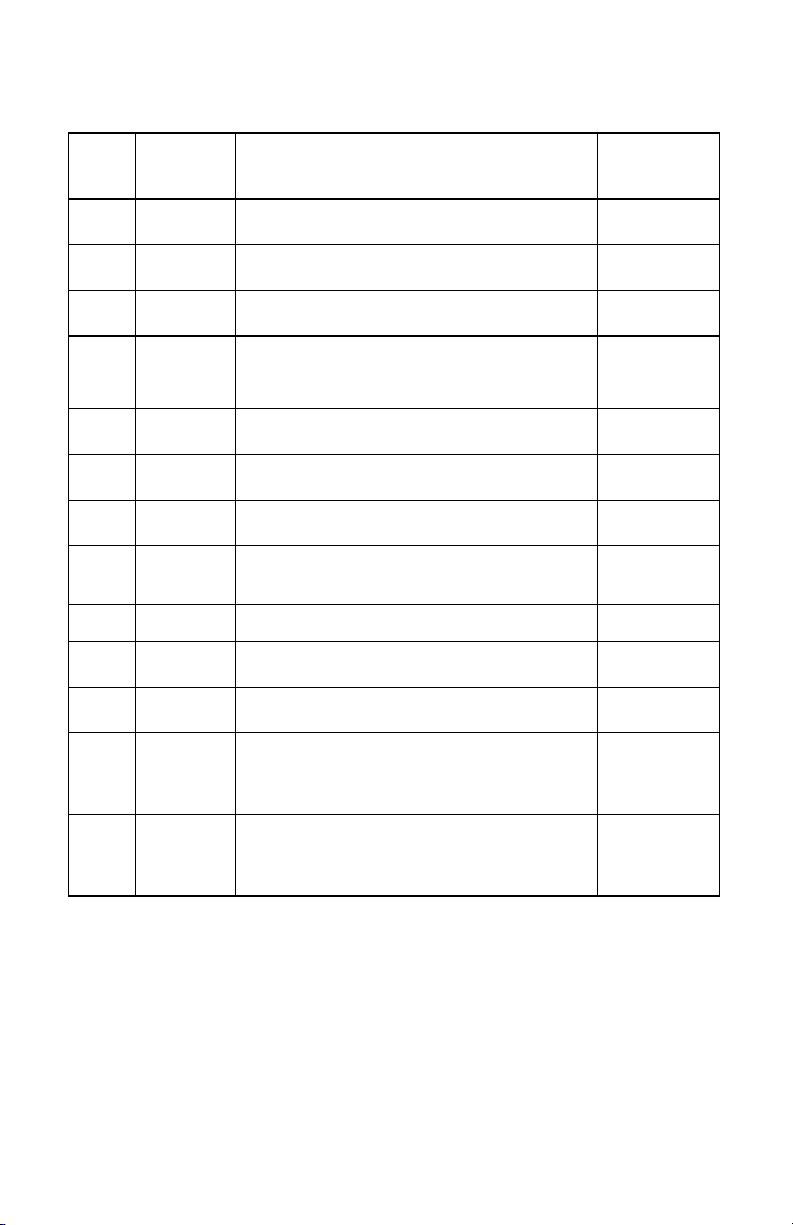

Rev

No. Date Details Author

01 05/30/14 Original Issue C. Swallow

02 05/01/15 US Version A. Konschak

03 05/25/16 Added Spares A. Konschak

04 02/10/17 Revised Program (mul language)

Changed menu opons A. Konschak

04a 03/01/17 Updated troubleshoong guide A. Konschak

04b 03/22/17 Updated Spares and Conguraon A. Konschak

04c 04/18/17 Added stop end adapters to P16 A. Konschak

04d 04/20/17 Updated blowing speed spec

Added min torque seng on P18 A. Konschak

04e 07/18/17 Changed company name A. Konschak

04f 03/06/18 Added shoulder strap A. Konschak

04g 03/26/18 Updated conguraon page A. Konschak

04h 02/15/21

Remove Polymetric Plates

Updated photos to reect latest changes

Update oered accessories A. Konschak

04i 04/26/21 Added remote control replacement A. Konschak

REVISION HISTORY

3

Contents

1. SAFETY INSTRUCTIONS........4

2. CRITICAL POINTS THAT DRAMATICALLY AFFECT THE OPERA-

TION OF THE BLOWN FIBER BLOWING MACHINE........8

3. GENERAL DESCRIPTION........10

4. SPECIFICATION........11

5. MAJOR ELEMENTS........12

6. OPERATING PROCEDURE........14

7. MAINTENANCE........25

8. PROCEDURE FOR CHANGING THE BLOWING PLATES........26

9. PROCEDURE FOR REPLACING TUBE CLAMP INSERTS AND IN-

FEED GUIDES........28

10. PROCEDURE FOR REPLACING DRIVE WHEELS........29

11. PROCEDURE FOR REPLACING AIR SEALS........30

12. CHECKING THE ODOMETER........31

13. DETERMINING MAXIMUM TORQUE SETTING........32

14. PROCEDURE FOR CHANGING DISPLAY LANGUAGE…..33

15. TROUBLESHOOTING GUIDE........34

16. MONTHLY SERVICE – CHECK LIST........35

17. CHANGEABLE PARTS AND ACCESSORIES ........36

18. SPARES…….38

GMP Limited Warranty can be found at hp://

www.gmptools.com/warranty/

4

1. SAFETY INSTRUCTIONS

THIS EQUIPMENT SHOULD BE USED ONLY BY PERSONNEL WHO

HAVE BEEN GIVEN THE APPROPRIATE TRAINING AND WHO ARE

COMPETENT TO USE IT.

THESE INSTRUCTIONS ARE TO BE MADE AVAILABLE TO OPERA-

TORS OF THIS EQUIPMENT AT ALL TIMES, FAILURE TO OBSERVE

THESE SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

WORK AREA AND GENERAL SAFETY

• Read and understand the operaon and maintenance

manual supplied with this equipment. Keep it in a

convenient place for future reference.

• Keep children and untrained personnel away from this equip-

ment while in operaon.

• Keep all guards and safety devices in place. Do not operate

this equipment with guards removed or damaged.

• Keep hands, feet and loose clothing away from moving parts.

• Always stop the machine and isolate compressed air and

electrical services to carry out servicing.

• Check machine before starng for worn or damaged parts.

Check for signs of loose nuts and bolts etc.

• If machine is le unaended, ensure that unauthorized use is

prevented. Never leave the machine unaended while in

use.

• Consider the use of safety barriers, especially when used in

public places, observe all statutory requirements for working

environments.

• Beware of pinch points involved with rotang components,

• Beware of hot surfaces, machine uses compressed air.

5

• When operang machine always wear appropriate safety

clothing, ear and eye protecon, hard hat, safety shoes and

leather gloves. The machine operates with compressed air at

up to 220 PSI (15 Bar).

• Prior to installaon ensure the tube route is connected

properly.

• Beware of exposed electrical contacts. Do not touch, or allow

metal objects to come into contact.

• Machine may cause addional re hazard if involved in an

exisng re due to compressed air.

• The machine must be operated on rm ground.

• Stay clear of pressurized airline and tube.

• Only use the machine for its intended purpose, to retrieve

ber blow air in the far end.

• The compressed air supply must not be allowed to enter the

air chamber before the lid has been securely ghtened.

• Ensure the ber exits easily from the pan. Place the pan a

sucient distance to allow the operator me to react should

the ber become tangled.

• The cable should enter the machine in a clean and dry condi-

on.

FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY OR DAM-

AGE TO THE BLOWN FIBER.

6

If a power supply is used and the connecng plug on the power

lead to the generator / (or supply) is unsuitable and requires re-

placement, the new plug must be correctly connected observing

the color codes as below.

IT IS THE RESPONSIBILITY OF THE USER TO ENSURE THAT THE

CONNECTIONS MEET THE ELECTRICAL REGULATIONS FOR THE

RELEVANT COUNTRY.

The Accelair 2 machine itself runs o a 24V supply connected via

a Binder Series 430 Socket. Should the connecng plug need re-

placement the Red wire is posive (+ve) (Pin 1) and the Black

wire is negave (-ve) (Pin 3), pin 2 is unused.

Brown (Live)

Yellow & Green (Earth)

Blue (Neutral)

7

GENERAL PNEUMATIC SAFETY INSTRUCTIONS

The GMP Accelair 2 Blown Fiber Blowing Machine is a pneu-

mac device, using pressurized air to project ber at high ve-

locies. Please observe the following precauons when oper-

ang the Blowing Machine:-

• Compressed air can cause ying debris. This could cause

personal injury. Always wear personal protecve equip-

ment.

• Ensure no personnel are in the manhole at the far end of

the ber run. Severe personal injury may result.

• Never open the machine when pressurized.

• Only authorized, fully trained personnel should operate the

air compressor.

GENERAL ELECTRICAL SAFETY INSTRUCTIONS

The machine has electronic and electrical power and control

circuits. Electric shock hazards exist that could result in severe

personal injury. Observe the following precauons to avoid

electrical hazards:

Do not operate in water. Do not expose the machine to rain.

Do not remove cover of the power supply or the base from the

Accelair 2 machine. There are no user serviceable parts inside.

Refer servicing to qualied service personnel.

8

2. CRITICAL POINTS THAT DRAMATICALLY AFFECT

THE OPERATION OF THE BLOWN FIBER BLOWING

MACHINE

• Cord seals in air chamber correctly ed to provide good

sealing.

• Correct blowing plates ed.

• Tube fully connected and pressure-tested.

• Tube connecng ngs are suitable for operang at com-

pressor supply pressure.

• Accelair 2 lid securely ghtened.

• Compressor capacity is suitable for size of tube being used.

• Fiber pan must be close to the machine, the ber should

leave the pan freely and enter the machine horizontally.

• Air chamber, drive wheel, blown ber must be clean and

free from debris, glass beads, sludge, dirt, water and lubri-

cant.

• The ber must be hand guided into the machine.

• Ensure the compressed air supply is not applied to the ber

unl approximately 30 meters of ber has been installed or

the machine begins to slow down.

• The compressed air moisture content needs to be carefully

controlled, it should be dry enough to prevent moisture

forming in the tubes yet not so dry to cause a stac build

up – GMP Products recommend the use of an air dryer with

a bypass.

9

DISCLAIMER

GMP takes care in the design of its products to ensure that the

cable is protected during installaon. Due to the variety and

dierent methods of ber manufacture the responsibility of

checking the ber compability with the equipment lies with the

operator. Therefore, GMP cannot accept liability for any damage

to the ber.

10

3. GENERAL DESCRIPTION

The Accelair 2 Fiber Blowing Machine has been developed to

provide a simple to use and reliable ber blowing soluon. The

unit is designed to t a ber range up to 3mm diameter, thereby

providing the complete range of blown ber installaon solu-

ons from one machine.

The Accelair 2 is a compact integrated ber blowing machine

beneng from full automaon and ber management; sophis-

cated ber protecon is implemented to ensure the ber me-

chanical and opcal integrity is maintained. The machine only

requires a single 24V D.C. electrical supply and compressed air to

operate.

GMP has designed a range of accessories aimed at providing the

complete soluon to blown ber installaon.

11

4. SPECIFICATION

Fiber

Compability:

Up to .8mm with buckle, up to 3mm with-

out buckle detecon

Blowing Speed: Manual control up to:

0-328 ./min (0-100m/min) without buckle

detecon

0-165 ./min (0-50m/min) with buckle

detecon

Compable Tubes: 3mm to 10mm

Automaon: In buckle mode machine is self-regulang

Air Supply: 15 Bar max working pressure complete with

suitable air condioning (drying)

Electrical

Supply:

Universal power supply (supplied as stand-

ard): 85-265V AC 50/60Hz input, 24V DC

2.2A output. Baery pack and vehicle

adapter available upon request.

Control: Remote user interface with backlit screen

provides all necessary informaon; includ-

ing current distance, speed, torque seng

and ber status.

Control interface supported languages:

English, French, German, Spanish,

Portuguese and Italian.

Machine size: H: 6.5" (166 mm) D: 7.2" (184 mm)

L: 4.7" (120 mm) Weight: 6.6 lbs. (3kg.)

Case size: H: 8.7" (220 mm) D: 18.9" (480 mm) L:

16.9" (430 mm)

Weight (case and unit): 26.5 lbs. (12kg

Environment: 0°C to +50°C (Usage)

-10°C to +70°C (Storage)

12

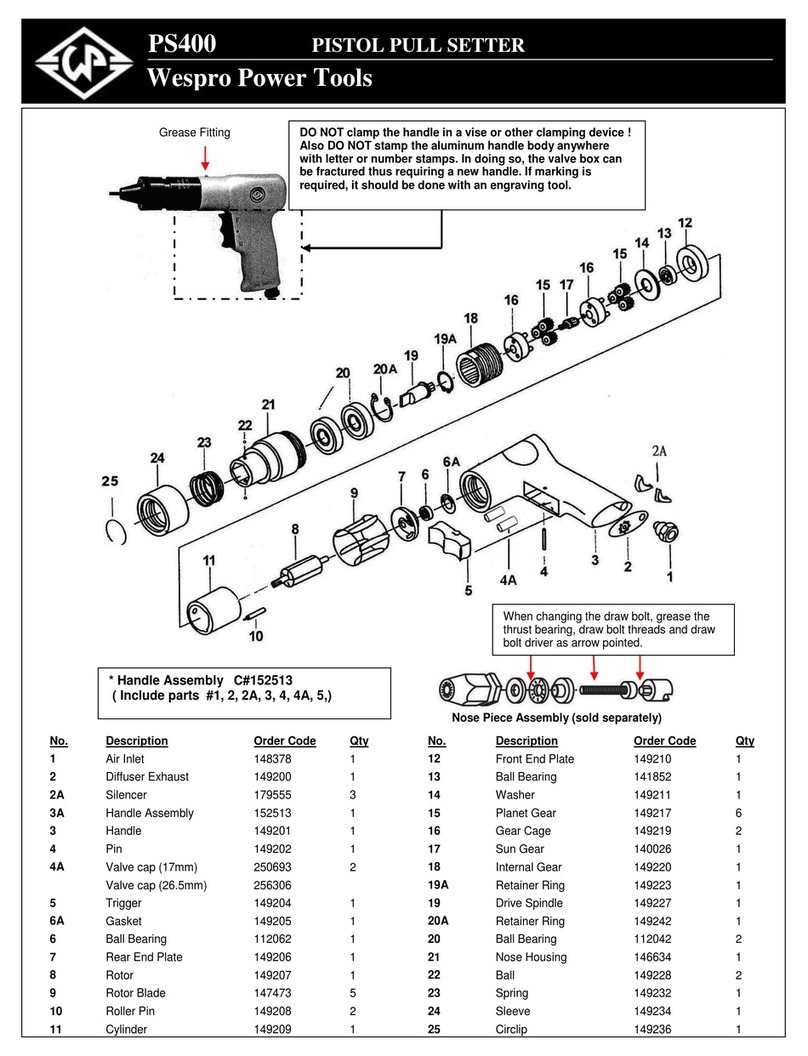

5. MAJOR ELEMENTS

Lid

Pressure

Gauge

Tube

Clamp

Buckle

Shule

Remote

Connecon

Buckle

Plates

Lid Locking

Screws

Sight Glass

Wheel Opening

Handle

Infeed Guide

Drive Wheels

LCD Display

Buckle Indicator

LED

User Interface

13

Air Control Valve

Air Connecon

24V Connecon

Lid Locking

Screws

Power Wires

Tools/Accessories

Universal AC-

Power Supply Remote UnitAccelair 2

Included with the Accelair is a removable

shoulder strap for added mobility when

working in mulple locaons.

14

6. OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR

MAINTAINING THIS FIBER BLOWING MACHINE:

• HAVE RECEIVED COMPREHENSIVE TRAINING IN THE USE OF

THIS MACHINE

• ARE COMPETENT TO USE IT

• AUTHORIZED TO USE IT

• HAVE READ AND UNDERSTOOD THIS MANUAL

GMP CANNOT BE HELD RESPONSIBLE FOR MISUSE OF THIS

EQUIPMENT.

SETTING UP THE TUBE AND FIBER

To begin an installaon rst we must connect the tube and t

the ber through the machine. A selecon of changeable parts

are available to suit any combinaon of tube and ber. Please

consult secons 8, 9 and 10 for the procedures to t these

changeable parts and secon 16 for a list of available parts.

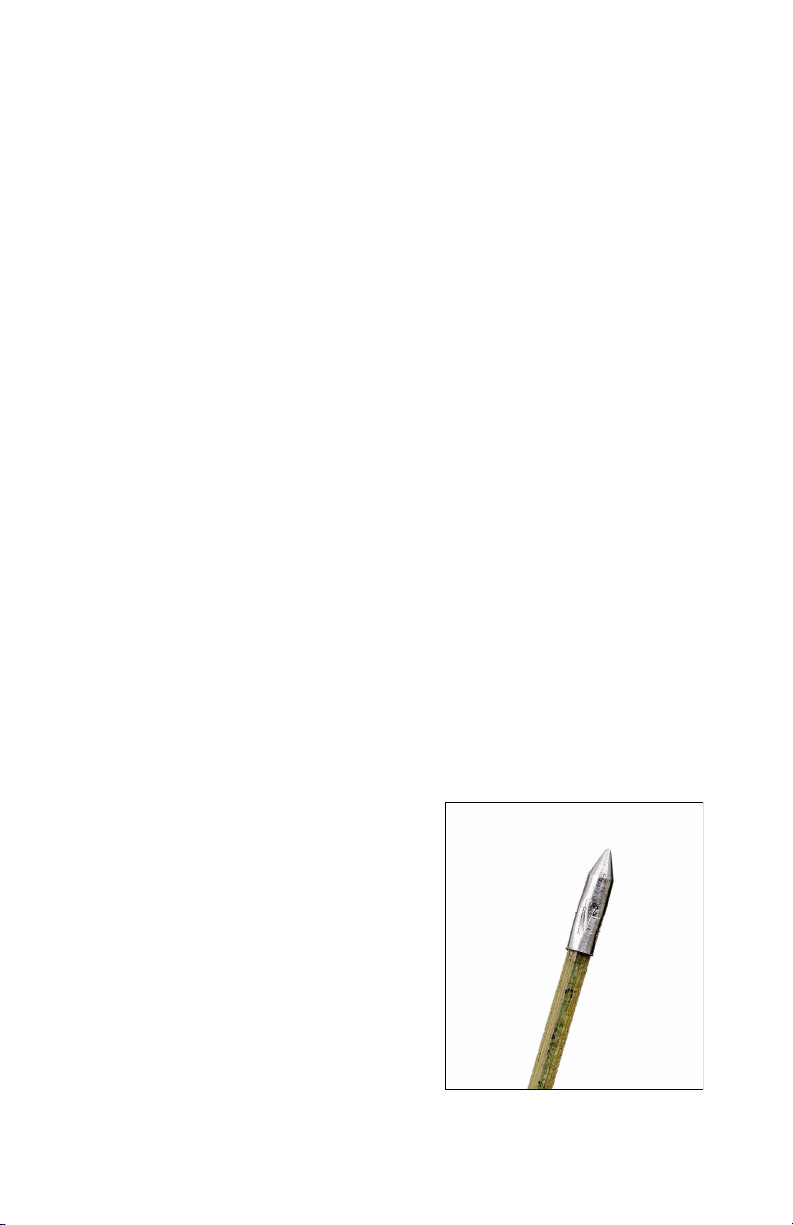

It is benecial and recommended to install a ber blowing bead

onto the end of the ber. Place the bead over the end of the

ber and use a small set of pliers to gently crimp it in place. Try

to deform the bead as lile as possible while holding it in place.

15

8. PROCEDURE FOR CHANGING THE BLOWING PLATES

The Accelair 2 uses two types of blowing plates. One type is for

use in conjuncon with the buckle funconality and one with-

out. The buckle plates use (4) M3 cap screws each to retain

them into the machine; the non-buckle plates use (3) each. The

supplied 2.5mm Allen wrench will be required for removal.

• Remove all retaining screws and li the plates out of the

machine.

• Inspect the condion of the air seal beneath the lower plate

and replace if necessary (photo overleaf).

• Replace plates of suitable size into the machine and ghten

the retaining screws rmly but take care not to damage the

aluminium threads.

Retaining

Screws

Retaining

Screws

Retaining

Screws

Retaining

Screws

No screw

No screw

16

Place the tube seal over the end of the

tube and insert into the machine as

shown with the tube ush up to the air

inlet and the seal

in the groove. Do

not allow the

tube to protrude

into the air inlet as this will restrict air

ow and performance.

Close the tube clamp by

pressing downwards; a

plunger will hold it in place.

Insert the end of the ber

into the tube and posion it

through the slot in the

buckle shule.

Open the drive wheels as

shown and place the ber in

the grooves on the buckle

plate and infeed guide.

17

The wheels are sprung and

will automacally close and

grip the cable once the han-

dle is released. Ensure the

ber runs smoothly through

the machine and is placed in

all grooves as shown.

Carefully close the lid,

ensuring the ber is not

caught or crushed.

Tighten the thumb screws

to seal the lid.

NEVER OPEN THE LID OF THE MACHINE WHEN IT IS UNDER PRES-

SURE, SERIOUS INJURY MAY OCCUR DUE TO ITEMS EXPELLED AT

HIGH VELOCITY.

GMP recommends the use of a stop end at the

end of the tube route to arrest the ber at the

end of the installaon.

4mm 3mm5mm

Adapters for 4 and 3mm microduct

18

FIBER INSTALLATION

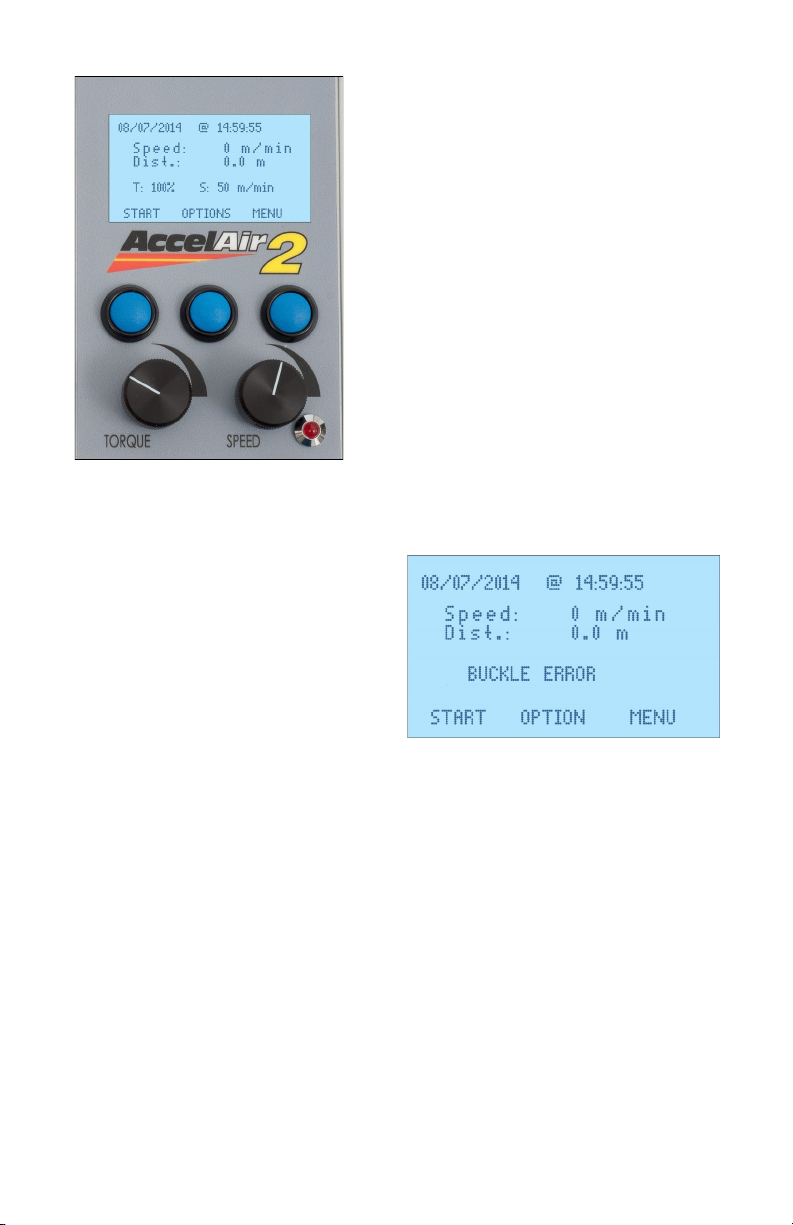

Insure that the remote control and the power supply is connect-

ed to the unit before plugging into the power source. Aer sup-

plying power, the LCD panel on the remote unit should power up

with the following display.

Select the opon by pressing

the relevant blue buon under

either YES or NO depending on

the type of installaon you

wish to carry out and the

plates ed to the machine.

The buckle sensor ulizes plates with the buckle shule - this

can be seen in the photo at the top of the previous page. Should

the wrong selecon be made this can be altered in the menu

system, this is detailed later in this secon.

Once the selecon is made, a conrmaon screen is briey dis-

played followed by one of the screens below:

If a job has not been nished then it will remain acve in

memory and the screen on the right will be visible. It is then pos-

sible to either resume that job or start a new job. The blue

buons allow navigaon through the menus and the funcons

of these buons are displayed on the screen. Starng a new job

will present you with the following display.

19

The two dials control the torque

seng and speed. Adjustment of

the torque seng is only relevant

when installing ber with the

buckle funconality disabled. The

torque should be set to a

minimum value of 20% when

buckle funconality is enabled to

ensure proper operaon.

This message will be displayed

if the buckle mode is selected

and the shule cannot be

detected. This is either because

the ber is buckled in the

machine or because you are

aempng to install with a

straight plate but have not

disabled the buckle

funconality.

20

To check the buckle funcon

and to allow a viewing point

for the ber we suggest a

small length of tube with a

clear connector be used in

the machine rst. Moving

the ber in and out should

be possible; the screen

should display that the

buckle shule is moving.

Should the incorrect buckle

mode be selected at power up

select ‘MENU’ if not already

there and then select

‘SETTINGS’. When on the buckle

sensor opon press ‘Change’ to

alter this funcon. You can then return to the menu and resume

acve job; the error will now have disappeared.

This manual suits for next models

1

Table of contents

Other GMP Power Tools manuals