Section 4

SYSTEM DESCRIPTION

4.1 - System Description

A complete system would typically consist of an appropriate SGA series DC power supply, the

GMW 231HC, a Senis magnetic field transducer, an electromagnet and finally an appropriate

computer and software or an external analog programming signal.

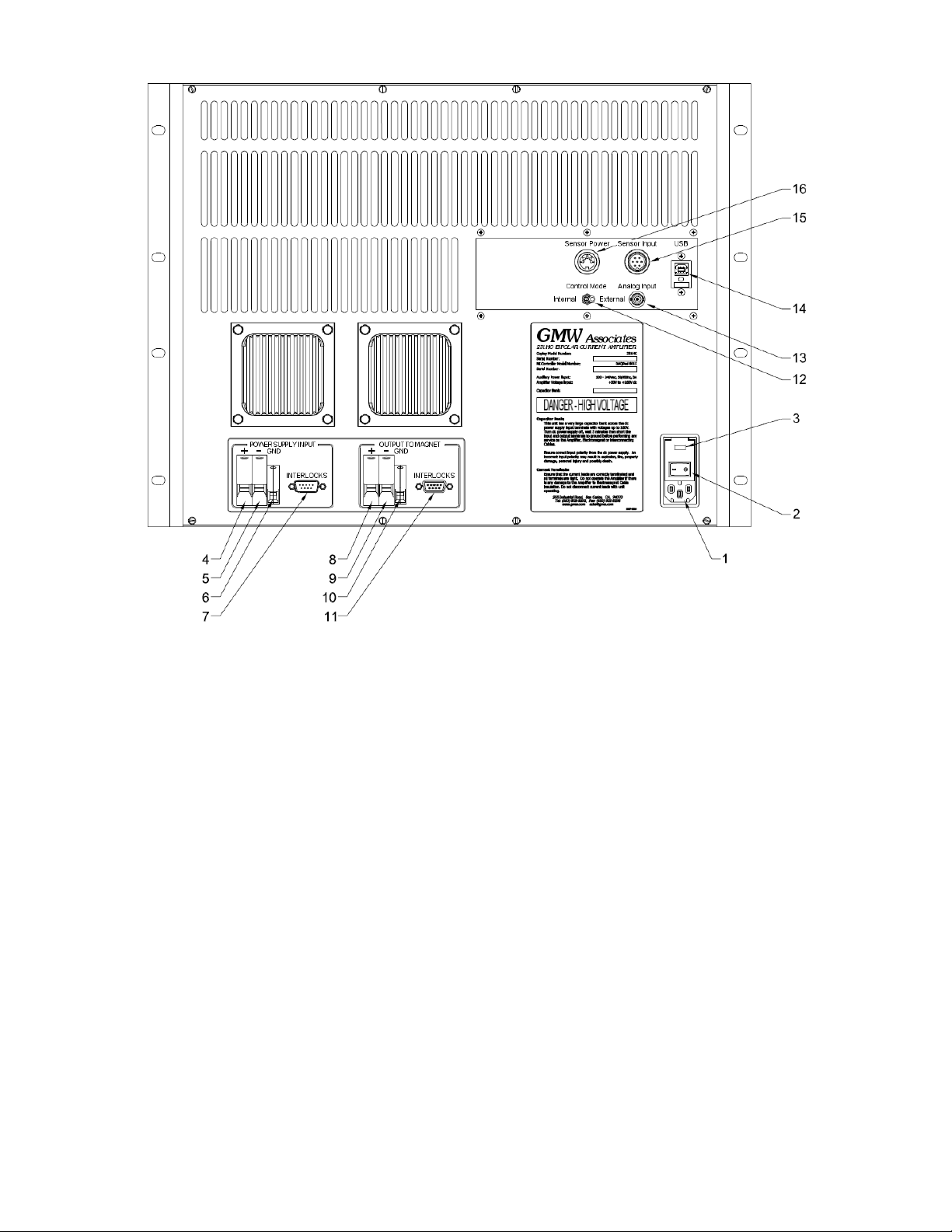

The DC Supply provides the 160V, 31A (or 160V, 63A) dc power to the 231HC Amplifier and is

buffered by the 231HC’s internal 200mF capacitor bank. The capacitor bank provides current

for short duration overloads of the DC Supply. The DC Supply is interlocked to the 231HC by

means of a relay contact in the 231HC. The Supply’s output is enabled on a closed contact,

providing protection should the interlock cable be disconnected. Two conditions will cause the

interlock relay to open, shutting down the DC Supply’s output: Failure in the auxiliary power

supply in the 231HC or a failure in the temperature or water flow interlocks on the electromagnet

load.

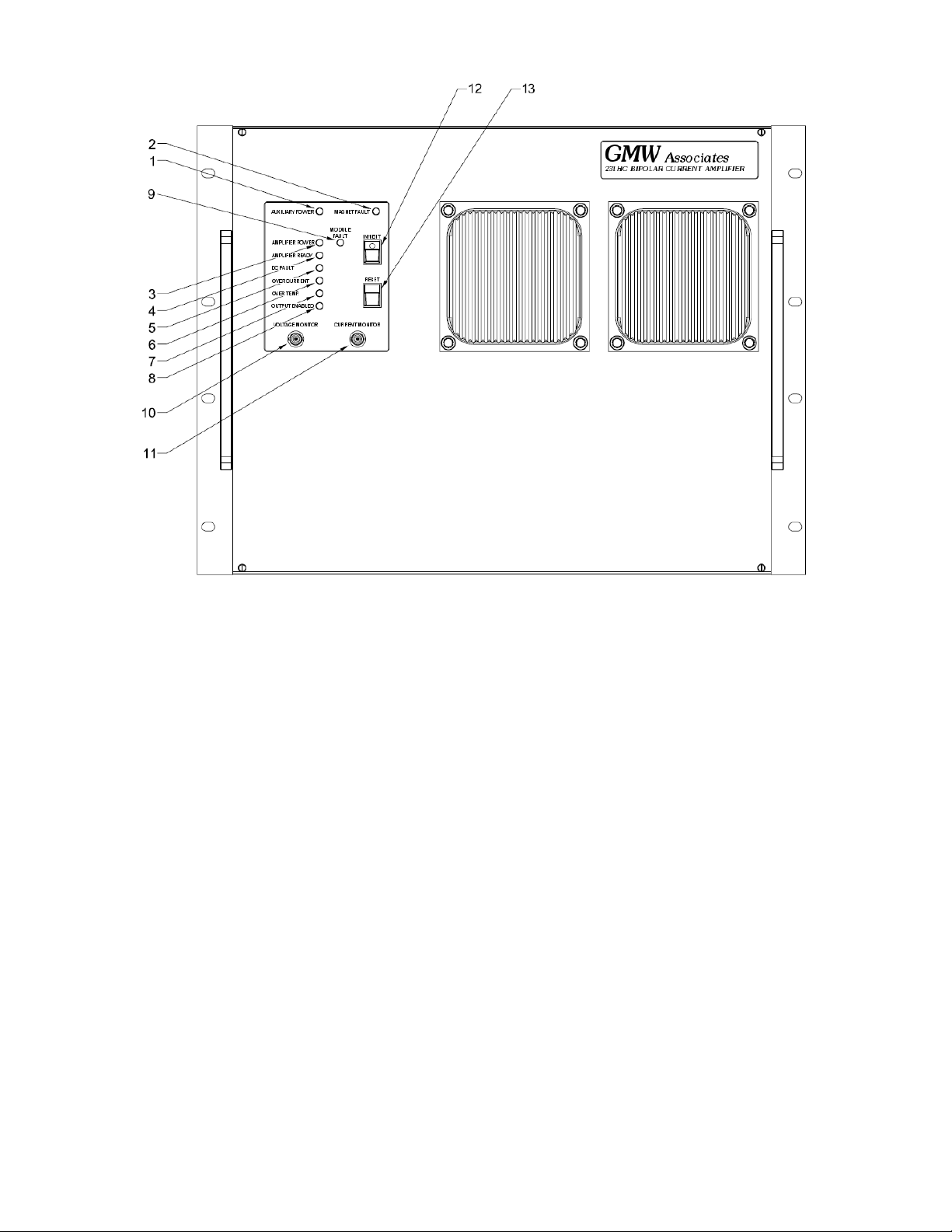

The 231HC Bipolar Current Amplifier integrates a Copley 231HC Amplifier with a 200mF

capacitor bank, a National Instruments USB-6251 Control with USB interface and an auxiliary

power supply into a single 19” rack mounting chassis.

The auxiliary power supply provides power for the cooling fans, interlocks and interface. It

also provides -12V and +12V (400mA each) on the rear panel for an optional external Senis

magnetic field transducer for magnetic field measurement and closed-loop field control. It is

important to note that if the auxiliary supply is not powered up, the DC Supply’s output will

be inhibited.

The interlock circuit for the magnet requires a ‘closed contact’ connection. Provision for

both magnet over temperature and water flow is provided, but they are connected in series

and simply ‘Magnet Fault’ is indicated on the status panel of the 231HC and when using the

NI USB-6251 DAQ, this information is available via the computer control software. In the

event of a magnet interlock fault, the output of the DC Supply is inhibited.

The NI USB-6251 DAQ interface provides computer control and monitoring of the system.

It uses a 16-bit analog output (±10V) to provide the drive signal to the Copley Amplifier.

The amplifier output voltage and current are monitored by two 16-bit input channels.

Complete amplifier and magnet interlock status is also monitored via its digital input

channels. When using an optional Senis magnetic field transducer, the field is read back on a

third 16-bit analog channel. For more information, please refer to the NI USB-6251 Manual

and section 4.5 in this manual.

The Copley 231HC Amplifier provides the power conversion from the fixed voltage DC

Supply to a programmable current source for the electromagnet. The current output is

proportional to the programming input of ±10V, supplied by either the NI USB-6251 or the

external analog voltage input. The amplifier is set by GMW to a full scale range of ±70A

output for ±10V input. For more information, please refer to the Copley Controls 231HC

Manual.

The optional Senis magnetic field transducer provides magnetic field monitoring for closed-loop

control feedback. It is powered by the auxiliary power supply in the 231HC.