5

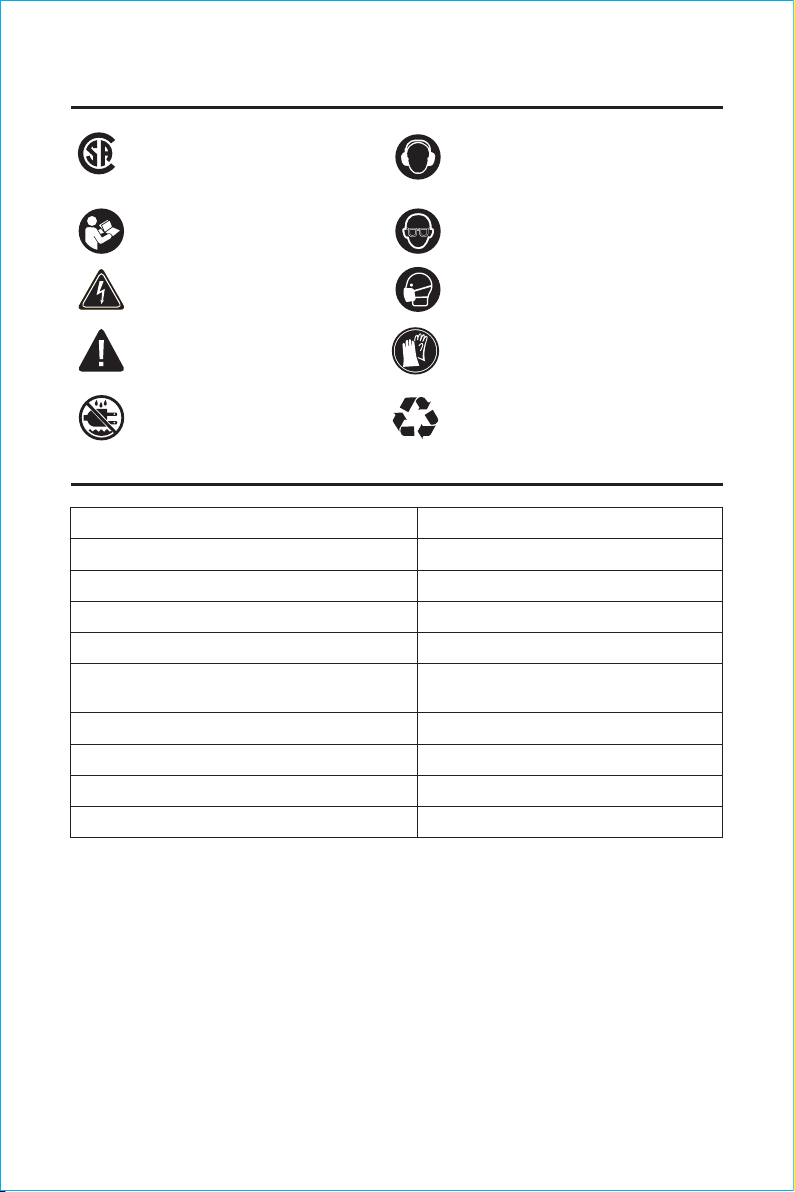

SAFETY RULES

5. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function - check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or replaced.

6. Only the maintenance work and troubleshooting activities described in

this instructions for use may be carried out. All other work must be

carried out by an expert.

7. Conversions, unauthorized modifications and the use of non-approved

parts are prohibited.

PRODUCT-SPECIFIC SAFETY WARNINGS

1. Make sure that you always stand to the side of the cutting disc.

2. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

3. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses only have impact resistant lenses,

they are NOT safety glasses.

4. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for

recommended accessories. The use of improper accessories may cause

risk of injury to persons.

5. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped

or if the cutting tool is unintentionally contacted.

6. Use only cutting discs that are suitable for the product.

7. Only use faultless cutting discs. Dismount damaged or worn cutting discs

immediately.

8. Never use segmented cutting discs.

9. Faults in the machine, including guards or diamond discs, should be

reported as soon as they are discovered. Never use the machine without

the guard in position.

10. Do not twist or bend workpieces.

11. Never cut several workpieces simultaneously - and do not cut bundles

made of several individual pieces. A workpiece can get caught in the

cutting disc and fly out of control.

12. Never cut workpieces on which there are ropes, cords, bands, cables

or wires containing such materials.