All contents copyright 2014, GoldWing RC Version 2.0, Feb 2014

Specifications

Wing Span: 126"(3200mm)

Length: 121"(3070mm)

Wing Area: 2806sq in(181sq dm)

Flying Weight: 38.5-44lbs(17.3-20Kg)

Gas Engine: 150CC-230CC Gas DA150 DA170 DA200 DLE170 DLE222 GP176

Radio: 6+ Channels

Servos: 11-13 servos required 250 oz to 420 oz (15-25kg/cm)

JR 8911, Savox 1256

All contents copyright 2014, GoldWing RC

Version 2.0, Apr 2014

Dear Customer,

The latest Goldwing SBACH342 170CC V4 aircraft are designed in conjunction with EG AIRCRAFT. EG

Aircraft will be sold in the USA with other territories covered by Goldwing.

Specifications of the aircraft are identical between the brands.

The structure of the new EXTRA&SBACH 170CC V4 aircraft has been further optimized, retaining the

current features of being built super light for 3D aerobatics yet are even stronger. Designed for the latest

generation of high output engines like the DA-170\DA200\DLE170\DLE222.

Goldwing RC is always keeping the pace with the latest developments in aerobatic flight. The

EXTRA&SBACH has the following Improvements:

1. Bigger control services. Up to 60 degrees of throw on all control surfaces. Best for more vibrant

aerobatic flight.

2.Packed in strong honeycomb board cartoon. Better protection during transportation.

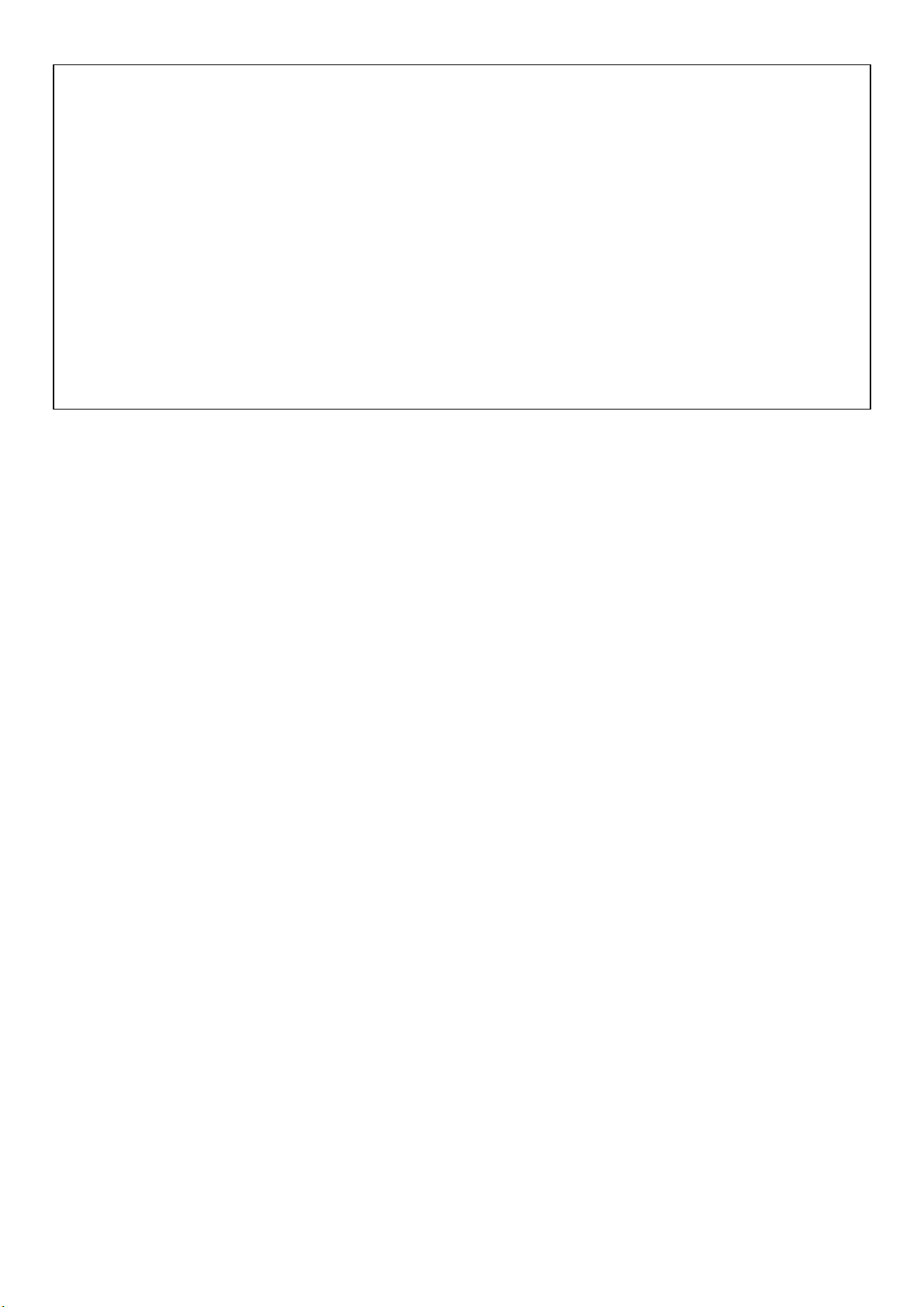

3.Improved carbon fiber tail wheel assembly, using CNC machined metal parts including aluminum tail

wheel hub.

4.Improved wheels with aluminum hub, built with more durable materials, and filled with rubber.

5.Using high quality cap head screws.

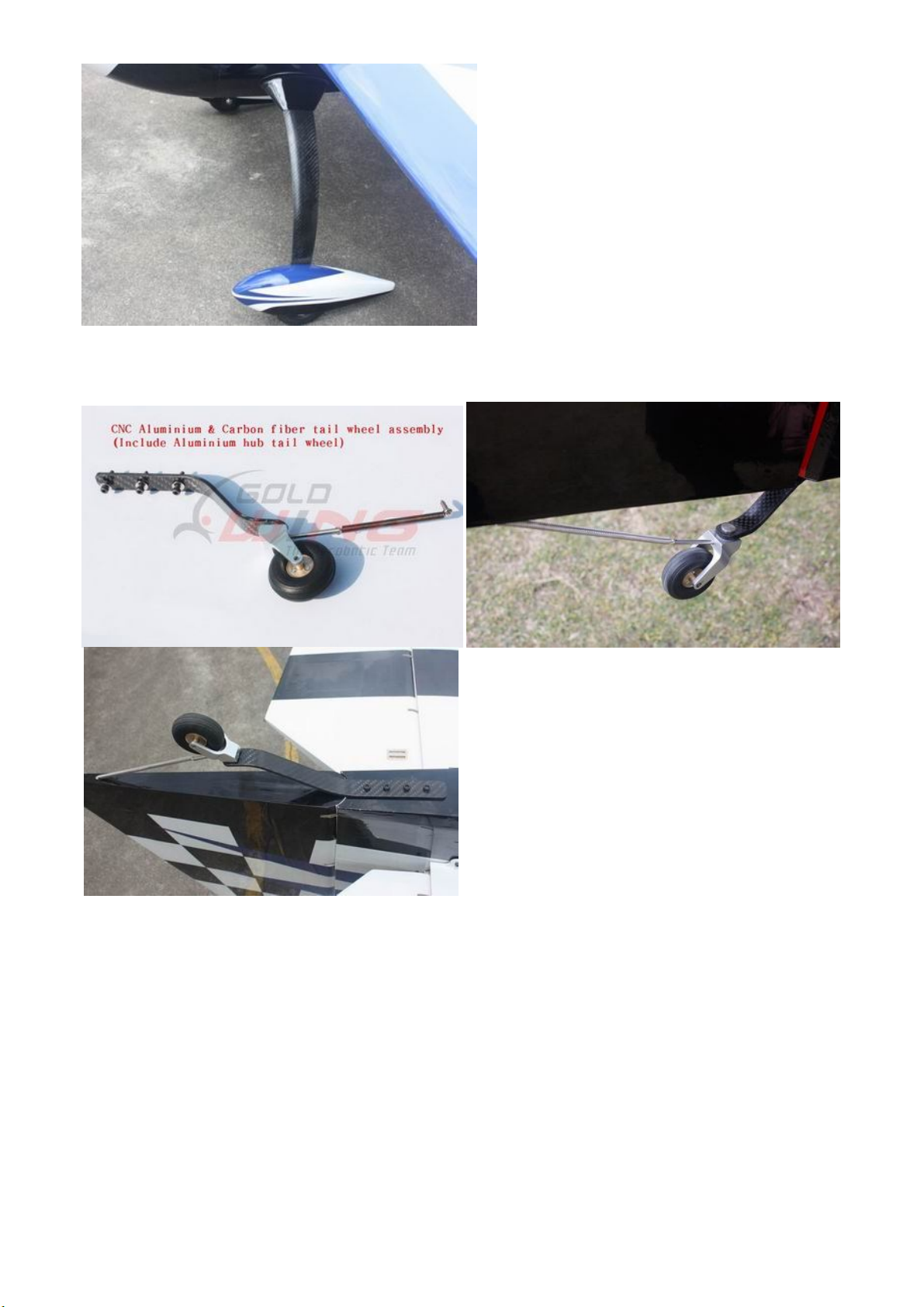

6.Spare covering included in the package. Convenient for repair.

7.Improved ball link assembly.

8.Upgraded to carbon fiber control horns.

9. Improved axles ,the material of the axle is stainless steel.

10. Include Side force generators.

11. Improved Pocket Style Scale Hinging.

12. This V4 new design with a longer fuselage moment arm aids the tracking of the model, giving it rock

sold precision flight. Making it perfect for modern day flight schedules for IMAC and Freestyle competitions.

A QUICK WORD ABOUT SAFETY AND RADIO CONTROL FLYING MODELS

With radio control aircraft, like any hobby or sport, there are certain risks. The operator of these models is

responsible for these risks. If misused or abused, you may cause serious bodily injury and/or damage to

property. With this in mind, you will want to be certain that you build your model carefully and correctly. If

you are not an experienced flier, have your work checked and ask for help in learning to fly safely. This model