9

• If the furnace is used in connection with a cooling

unit, install the furnace upstream or in parallel with

the cooling coil. Premature heat exchanger failure

willresult if thecoolingcoil isplaced upstreamofthe

furnace.

For vertical (upflow or downflow) applications, the

minimum cooling coil width shall not be less than

furnace width minus 1”. Additionally, a coil installed

aboveanupflowfurnaceorunderacounterflowfurnace

maybethesame width asthe furnace ormay beone

size larger than the furnace. Example: a “C” width

coil may be installed with a “B” width furnace.

Forupflowapplications,thefrontofthecoilandfurnace

must face the same direction.

• Ifthefurnaceisinstalledinaresidentialgarage,position

the furnace so that the burners and ignition source are

located not less than 18 inches (457 mm) above the

floor. Protect the furnace from physical damage by

vehicles.

• Ifthefurnaceisinstalledhorizontally,ensuretheaccess

doorsarenotonthe“up/top”or“down/bottom”sideofthe

furnace.

• Donotconnectthisfurnacetoachimneyfluethatserves

aseparateappliancedesignedtoburnsolidfuel.

• OnCounterflowInstallations,theairconditioningcoilmust

bedownstreamonthesupply(positive)sideofthefurnace

heatexchanger.

•Counterflow Installation over a noncombustible floor.

Beforesettingthefurnaceovertheplenumopening,ensure

the surface around the opening is smooth and level.A

tightsealshouldbemadebetweenthefurnacebaseand

floor by using a silicone rubber caulking compound or

cementgrout.

•Counterflow Installation over a combustible floor. If

installationoveracombustiblefloorbecomesnecessary,

use an accessory subbase (see Specification Sheet

applicableforyourmodelfordetails.) Aspecialaccessory

subbase must be used for upright counterflow unit

installationsoveranycombustiblematerialincludingwood.

Refertosubbaseinstructionsforinstallationdetails.Follow

theinstructionswiththe subbase for properinstallation.

Do not install the furnace directly on carpeting, tile, or

other combustible material other than wood flooring.

(NOTE: The subbase will not be required if an air

conditioning coil is installed between the supply air

openingonthefurnaceandthefloor.)

CLEARANCESANDACCESSIBILITY

POSITION SIDES REAR FRONT BOTTOM FLUE TOP

Upflow 0" 0" 3" C 0" 1"

Horizontal 6" 0" 3" C 0" 6"

*MVM96* MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS

(INCHES)

C = If placed on combustible floor, floor MUST be wood only.

NOTES:

• For servicing or cleaning, a 24” front clearance is required.

• Unit connections (electrical, flue and drain) may necessitate

greater clearances than the minimum clearances listed above.

• In all cases, accessibility clearance must take precedence over

clearances from the enclosure where accessibility clearances

are greater.

POSITION SIDES REAR FRONT BOTTOM FLUE TOP

Downflow 0" 0" 3" NC 0" 1"

Horizontal 6" 0" 3" C 0" 6"

*CVM96* MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS

(INCHES)

C = If placed on combustible floor, floor MUST be wood only.

NC = For installation on non-combustible floors only. A combustible subbase

must be used for installations on combustible flooring.

NOTES:

• For servicing or cleaning, a 24” front clearance is required.

• Unit connections (electrical, flue and drain) may necessitate

greater clearances than the minimum clearances listed above.

• In all cases, accessibility clearance must take precedence over

clearances from the enclosure where accessibility clearances

are greater.

Installationsmustadheretotheclearancestocombustiblemate-

rialstowhichthisfurnacehasbeendesigncertified. Theminimum

clearanceinformationforthisfurnaceisprovidedontheunit’sclear-

ancelabel. Theseclearancesmustbepermanentlymaintained.

Clearancesmustalsoaccommodateaninstallation’sgas,electri-

cal,anddraintrapanddrainlineconnections. NOTE: Inaddition

totherequiredclearancestocombustiblematerials,aminimumof

24inchesserviceclearancemustbeavailableinfrontoftheunit.

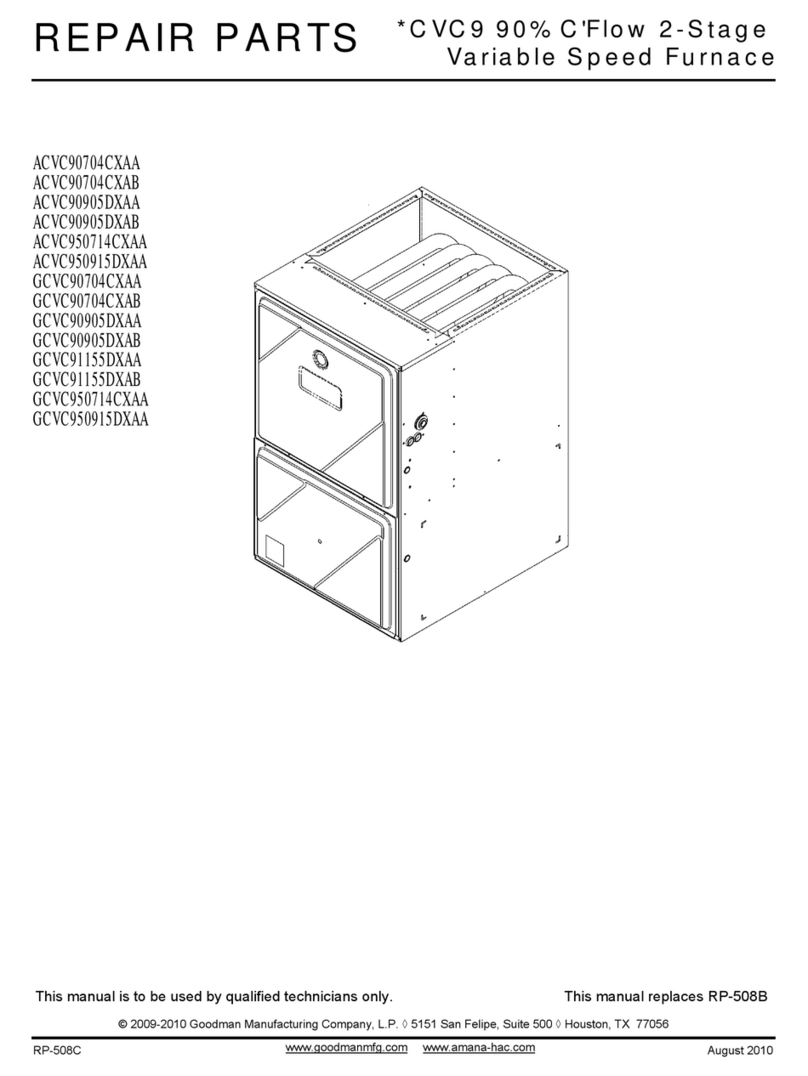

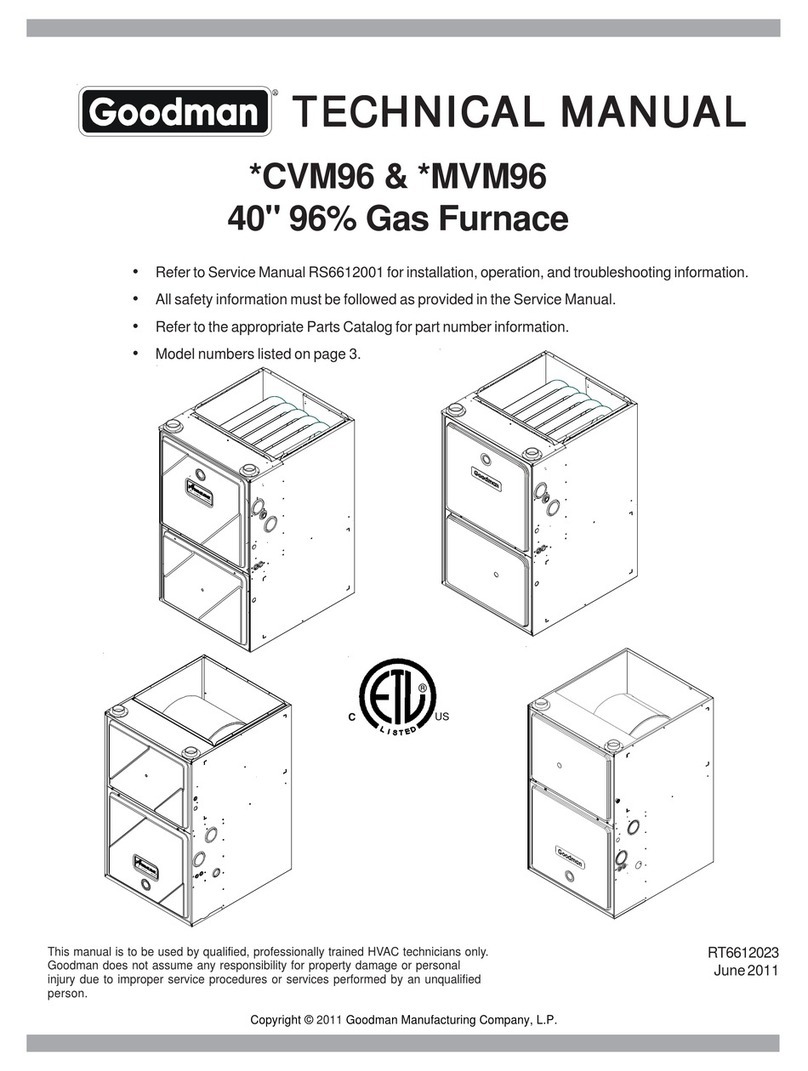

TOP

BOTTOM

SIDE SIDE SIDE

TOP

BOTTOM

Upflow Counterflow Horizontal

EXISTINGFURNACEREMOVAL

NOTE:Whenanexistingfurnaceisremovedfromaventingsys-

temservingotherappliances,theventingsystemmaybetoolarge

toproperlyventtheremainingattachedappliances.

ThefollowingventtestingprocedureisreproducedfromtheAmeri-

canNationalStandard/NationalStandardofCanadaforGas-

Fired Central Furnaces ANSI Z21.4, CSA-2.3 latest edition

Section 1.23.1.

The following steps shall be followed with each appliance con-

nectedtotheventingsystemplacedinoperation,whileanyother

appliancesconnectedtotheventingsystemarenotinoperation:

1. Seal any unusedopeningsintheventingsystem;

2. Inspecttheventing system forproper sizeandhorizon-

tal pitch, as required by the National Fuel Gas Code,

ANSIZ223.1 orthe Natural Gasand PropaneInstalla-

tionCode, CSAB149.1-05and theseinstructions.De-

termine that there is no blockage or restriction, leak-

age,corrosionand other deficiencieswhichcouldcause

anunsafecondition.