AQUA ECOLOGIC | instructions for use, maintenance and installation | September 2015

9

DANGER !

It is forbidden to install shut-off valves for the flow (draft) of air (flap valves that can prevent airflow or disable

drafts).

ATTENTION

If the ejection path of smoke creates such a bad draft, of a bad flow of air (many curves, improper completion

of the ejection of smoke, constriction, etc.) discharge of smoke can be bad, or in a situation like this smoke

discharging is not as good as it could be.

The smoke ejection system from the stove operates under negative pressure in the stove chamber and

with mild pressure from the smoke drain pipe. It is very important that the smoke extraction system is

hermetically closed (sealed). This requires the use of a smooth tube on the inside. First of all you must

carefully study the plan and structure of the room when the smoke extraction pipe is set up through the

walls and roof, so that the installation of pipes is performed properly in accordance with the standards of

fire protection.

You should first ensure that the room where the stove is located has enough air for combustion. It is

advisable to periodically performs check so as to ensure that the combustion air comes right up to the

combustion chamber. The stove operates at 230 V ~ 50 Hz. Make sure that the electrical cord is not

underneath the furnace, to be away from the stove, to be away from hot spots, and not to touch any sharp

edges that it could interdict. If the stove is electrically overloaded, this can lead to shortening of the lifetime

of the electronics of the stove.

Never turn off the power supply by pulling the plug when there is a burning flame in the stove. This

could jeopardize the proper functioning of the stove.

4.2 THE SMOKE EXHAUST SYSTEM

The smoke exhaust must be carried out in accordance with existing standards. Exhaust gas tube should

be well sealed (see Figures 1-7).

For smoke exhaustion, one can also use classic brick chimneys while flues can also be made of pipes that

need to be well insulated (double wall) and sealed, to avoid creating condensation in them.

The drain tube absolutely must not be connected to other systems of any kind, such as the systems where

the smoke is removed from the combustion chamber, exhaust grilles or air distribution system, etc. Also,

the smoke exhaust must not be set up in enclosed or semi-enclosed areas such as garages, narrow

corridors, underground passages, or at any other places where they is smoke. When the stove is connected

to the exhaust gas pipeline, it is necessary to bring professional chimneysweep to verify that the chimney

does not even have the tiniest cracks or fissures. If in the exhaust gas chimney there are such cracks, the

pipe for smoke exhaustion must be wrapped in insulation for proper functioning.

For this purpose, the tubes that can be used are solid and made of painted steel (minimum thickness 1.5

mm) or from stainless steel (minimum thickness 0.5 mm).

The smoke extraction system (chimney) out of metal pipes must have a grounding in accordance with

existing standards and regulations. Grounding is required by law.

The grounding connection must be separated from the grounding for the stove.

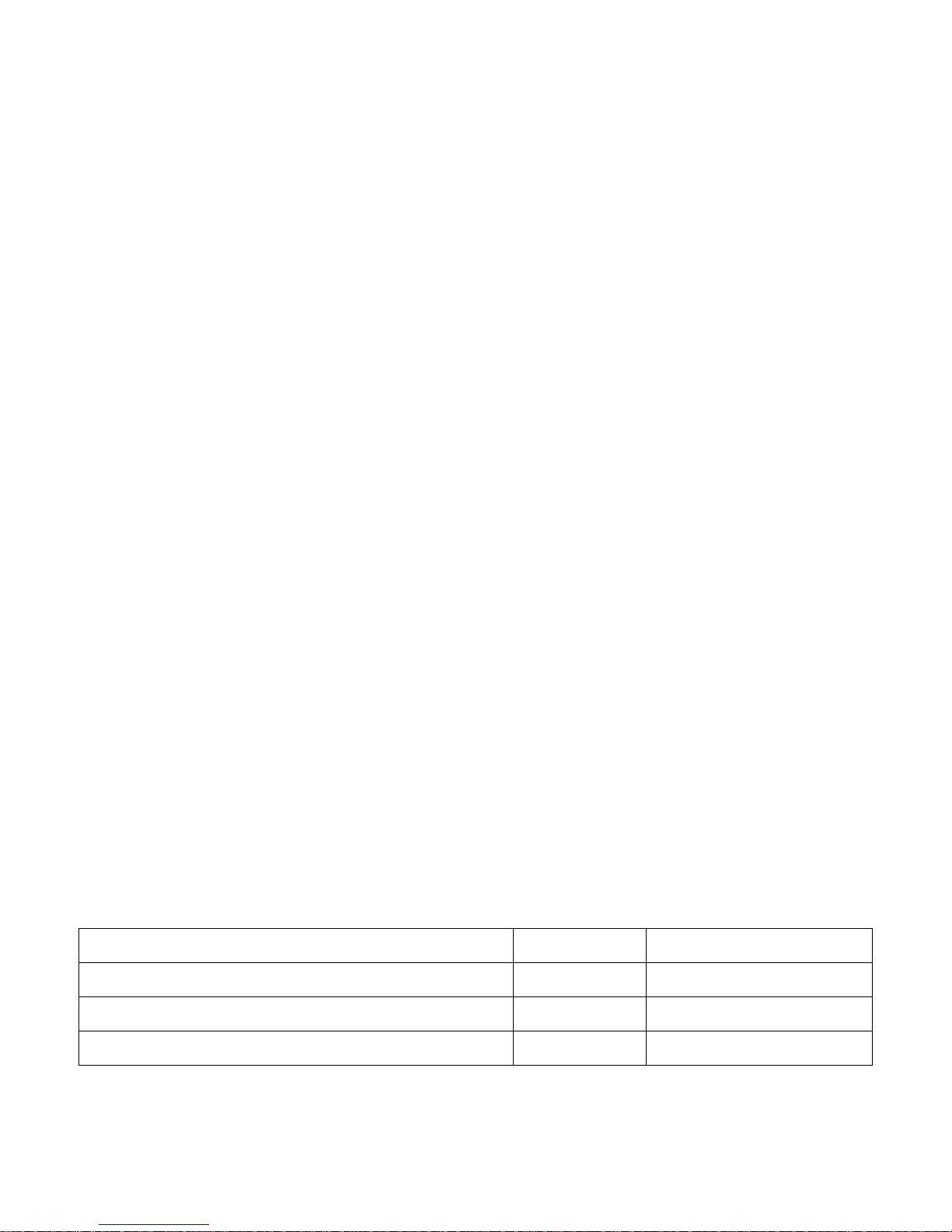

The smoke exhaustion pipe must be done according to the standards in terms of dimensions

and materials used for its construction (Figure 1).

A) The top of the chimney is resistant to wind