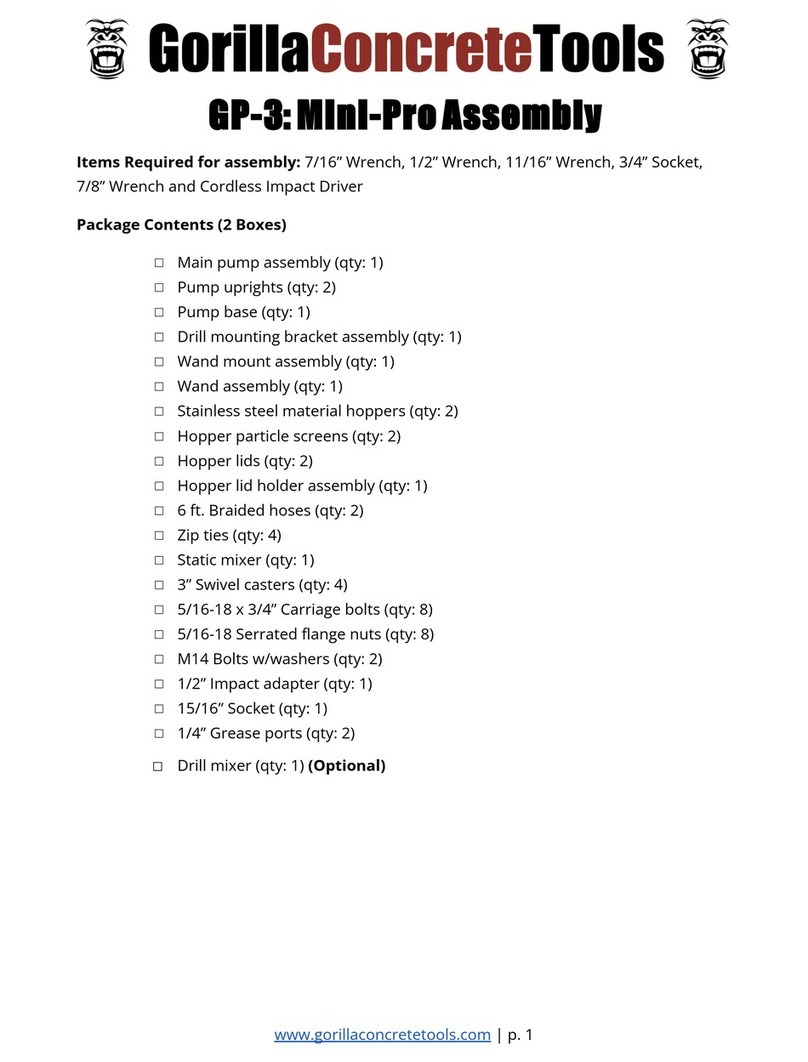

Call (+1(440)-236-5112) or visit our website (www.gorillaconcretetools.com) for our terms and conditions

Page 6

Read the manufacturer's safety data

sheet and instructions for the material

you will be using.

Mix components according to the

manufacturer's instructions.

After mixing components, pour Part A

into Part A tank, and then, pour Part B

into Part B tank. (Fig. 1)

Filling Pump:

1.

2.

3.

Never cross contaminant tanks.

Clean off the manifold with the static

mixing tip removed. (Fig. 2)

Dispense material into a waste container

to check for a smooth, air-free flow of

both components. Make sure that there

are two smooth, consistent streams.

If the streams of material are not

consistent, check for blockages and

clean the manifold accordingly and

repeat the previous steps.

Attach a new static mixing tip onto the

manifold.

If dispensing a cure sample, follow long-

term interruptions directions below.

Preparing for Use:

1.

2.

a.

3.

a.

____________________________

Short Term (5 or so minutes): periodically

trigger applicator wand to dispense material

into a waste container every 30-45 seconds to

ensure the material in static mixing tip does not

set.

Long Term (lunch break or cure sample):

remove static mixing tip and discard. Pump

grease into fittings on the manifold. Upon

returning to work, re-install a new static mixing

tip.

Work Interruptions:

1.

2.

Figure 1

Figure 2

____________________________

Figure 2

Pump Set Up

Pump Set Up