GORMAN-RUPP GHS Series User manual

Other GORMAN-RUPP Water Pump manuals

GORMAN-RUPP

GORMAN-RUPP 811/2E3-B Application guide

GORMAN-RUPP

GORMAN-RUPP 02K11-B Application guide

GORMAN-RUPP

GORMAN-RUPP 13D1-(19) PPO User manual

GORMAN-RUPP

GORMAN-RUPP AMT 370F-97 Assembly instructions

GORMAN-RUPP

GORMAN-RUPP PA Series User manual

GORMAN-RUPP

GORMAN-RUPP AMT 370F-95 Assembly instructions

GORMAN-RUPP

GORMAN-RUPP 0 SERIES Application guide

GORMAN-RUPP

GORMAN-RUPP 2P5X Assembly instructions

GORMAN-RUPP

GORMAN-RUPP SF4F Application guide

GORMAN-RUPP

GORMAN-RUPP T8A60-B/F Installation and operating instructions

GORMAN-RUPP

GORMAN-RUPP AMT 3391-V9 Assembly instructions

GORMAN-RUPP

GORMAN-RUPP U3A60S-B User manual

GORMAN-RUPP

GORMAN-RUPP IPT Series User manual

GORMAN-RUPP

GORMAN-RUPP SFDV3B Application guide

GORMAN-RUPP

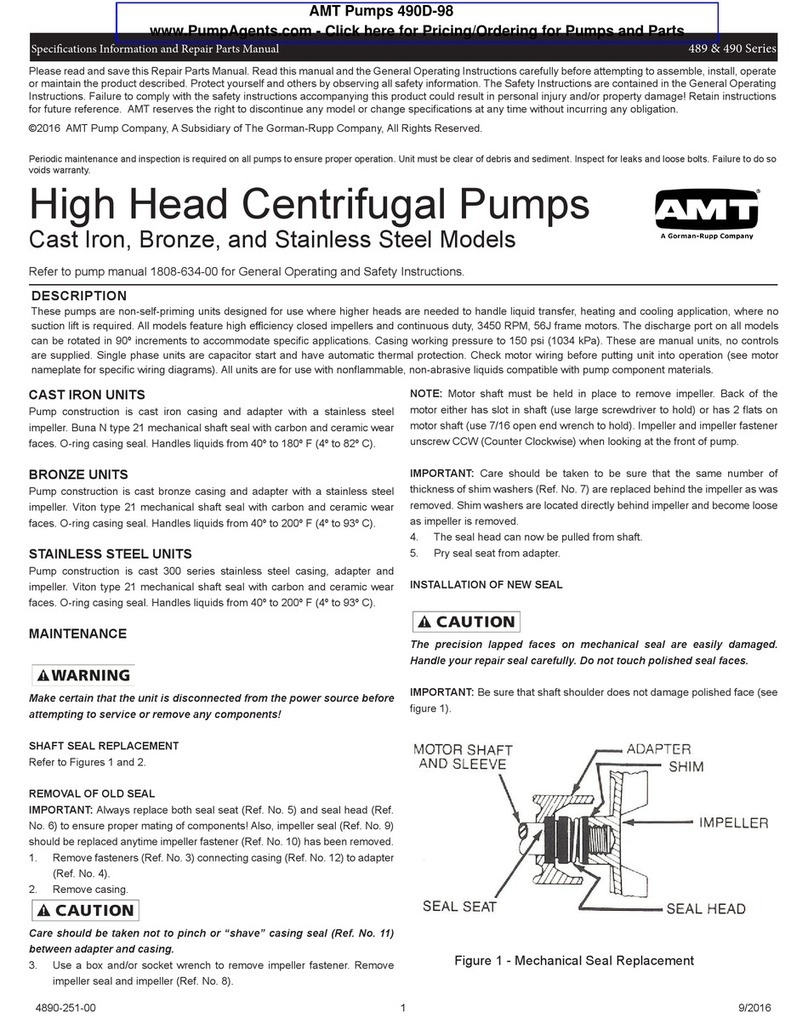

GORMAN-RUPP AMT 489 Series Assembly instructions

GORMAN-RUPP

GORMAN-RUPP SFV Series Installation and operating instructions

GORMAN-RUPP

GORMAN-RUPP 60 Series User manual

GORMAN-RUPP

GORMAN-RUPP AMT 316A-95 User manual

GORMAN-RUPP

GORMAN-RUPP AMT IPT 4222-V5 Assembly instructions

GORMAN-RUPP

GORMAN-RUPP 16A20-B User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual