MR-04427 SM SERIES PUMPS

TROUBLESHOOTING PAGE B - 3

Be certain to refer to the wiring diagram(s)

in the Installation Section of this manual be

fore reconnecting any electrical compo

nents which have been disconnected.

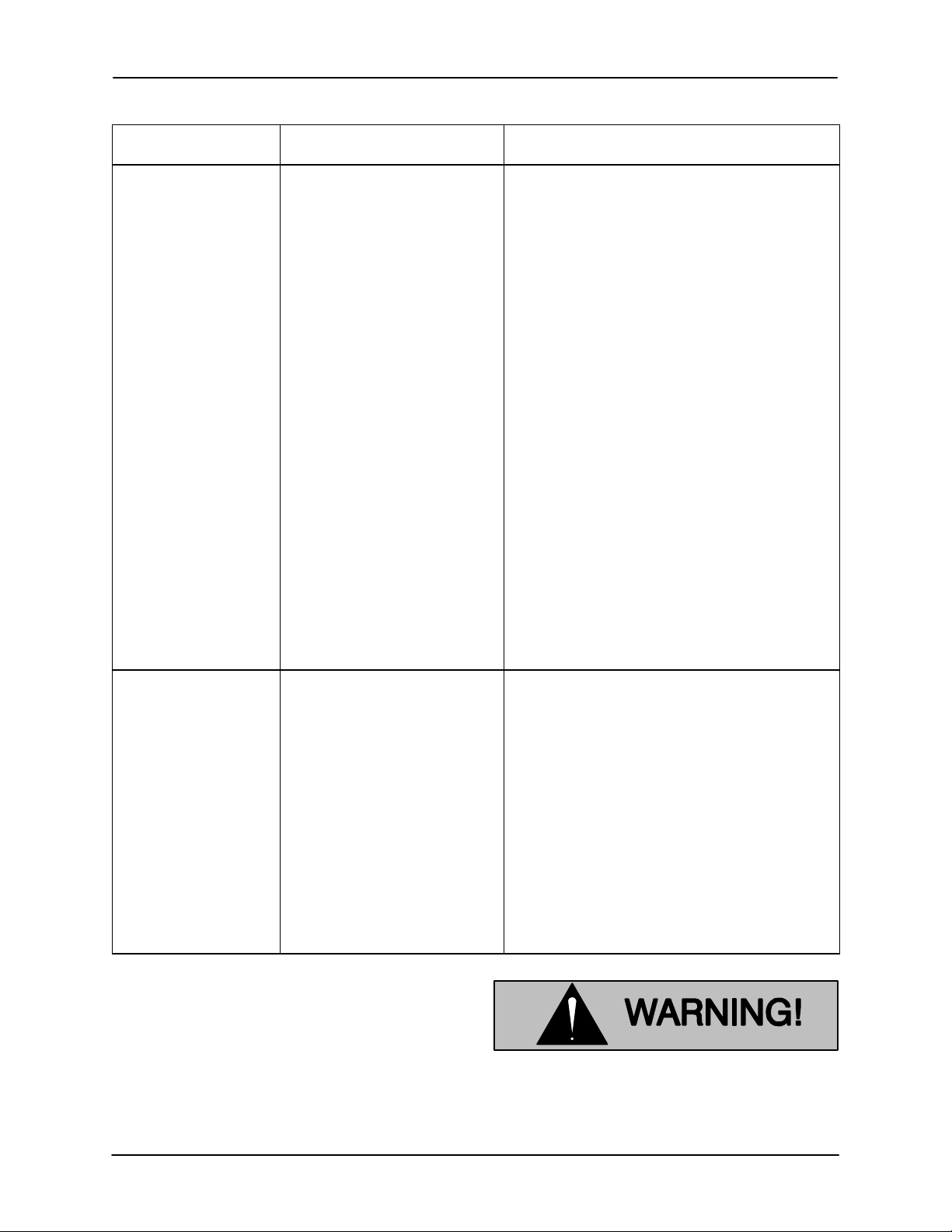

Test Equipment

A volt/amp/ohmmeter and megohmeter of ade

quate range and quality will be required to conduct

the following electrical tests. The suggested equip

ment indicated below is commercially available, or

an equivalent substitute may be used.

Equipment Use

Ammeter To check AC Voltage

and current (amperage)

Ohmeter To measure resistance

(ohms) to ground

Voltage Imbalance

Each phase of the incoming three‐phase power

must be balanced with the other two as accurately

as a commercial voltmeter will read. If the phases

are balanced, check out the motor as described

below. If the phases are out of balance, contact

your power company and request that they correct

the condition.

a. Use a voltmeter, amprobe, or equivalent me

ter to read the voltage across terminals 1 &

2, 2 & 3, and 1 & 3 in the control box. All three

measured voltages must be the same, as

accurately as the meter will read. If possible,

measure the voltage with the pump off, with

the pump running but out of the water, and

with the pump running in the water at full

load. All the measured voltages at each con

dition must be the same.

b. Use an amprobe or equivalent meter to

measure the current draw of each phase

while the pump is running at full load and at

no load. All three amperage readings must

be the same at each condition, as accurate

ly as the meter will read. Nominal amperage

values are listed in Table 1, but these apply

only when the actual voltage at the site is the

nominal voltage listed.

c. If the voltages are balanced with the pump

off, but are unbalanced when the pump is

running, a thorough check of the power

source, all interconnecting cables, and the

pump motor is required to isolate the defect.

Motor And Motor Power Cable Continuity

To check continuity, zero‐balance the ohmmeter

set at the RX1 scale, and test as follows:

a Disconnect the motor power cable leads

from the control box and connect the test

leads to any two of the three power cable

leads (not to the green ground lead or yellow

ground check lead). If there is a high resis

tance reading on the ohmmeter, there is an

open or broken circuit cause a break in the

power cable or motor windings, or by a bad

connection between the motor and the pow

er cable. Switch one test lead to the third

power lead, and test again.

b. If an open or broken circuit is indicated,

check the power cable for obvious damage,

and replace as necessary (see MAINTE

NANCE AND REPAIR). If there is no appar

ent damage to the motor cable, remove the

terminal housing (see MAINTENANCE

AND REPAIR) and check the continuity of

each power cable lead at the terminal posts.

c. If an open circuit still exists after each lead

(terminal) has been tested and tightened,

then the entire motor power cable must be

replaced. Splicing or other means of repair

are not recommended.

d. If no break is found in the power cable,

check the motor leads for continuity. If the

test reading indicates an open or broken cir

cuit, there is an open circuit in the motor.

NOTE

It is recommended that a pump with a defective mo

tor be returned to Gorman‐Rupp, or to one of the

Gorman‐Rupp authorized Submersible Repair

Centers.