4 Gossen Metrawatt GmbH

Measurement results are displayed at the test

instrument.

Note!

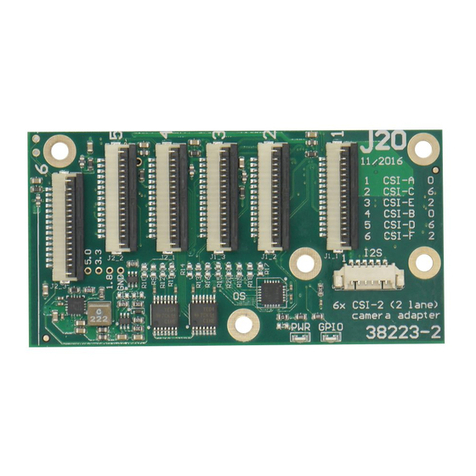

The AT3-III E test adapter is equipped with

electronic error monitoring which discon-

nects the device under test from the mains in

the event of fault currents of greater than

18 mA.

2 Safety Precautions

The test adapter has been manufactured and

tested in accordance with the following regula-

tions:

IEC 61010-1/DIN EN 61010-1/VDE 0411-1 “Reg-

ulations for electronic testers and controllers, part

1: Safety measures for electrical measuring instru-

ments”

DIN VDE 0404 “Devices for technical safety test-

ing of electrical equipment, parts 1 and 2.”

EN 61326-1 product standard EMC requirements.

Safety is only assured for the user and the test

adapter when used for its intended purpose in

combination with the test instruments mentioned

in chapter 1 "Applications".

In order to maintain flawless technical safety con-

ditions, and to assure safe use, it is imperative that

you read these operating instructions thoroughly

and carefully before placing your test adapter into

service, and that you follow all instructions con-

tained herein.

Due to the fact that all tests performed with the AT3-

III E must be executed in combination with a test instru-

ment mentioned in chapter 1 "Applications", you must

also read the safety precautions and liability limitations

included in the operating instructions for this instru-

ment.

Observe the following safety precautions:

Attention!

!If the red LED (10) remains lit even after

the AT3-III E has been disconnected from

the mains and connected once again, the

test adapter is defective.

If this is the case,

the AT3-III E must be removed from service

and repaired before it is used again.

• In order to assure compliance with technical

safety requirements, the AT3-III E test adapter

should only be repaired by the manufacturer.

• The AT3-III E must be disconnected from the

mains and from the test instrument before it is

opened.

Measurements within electrical systems are prohibited!

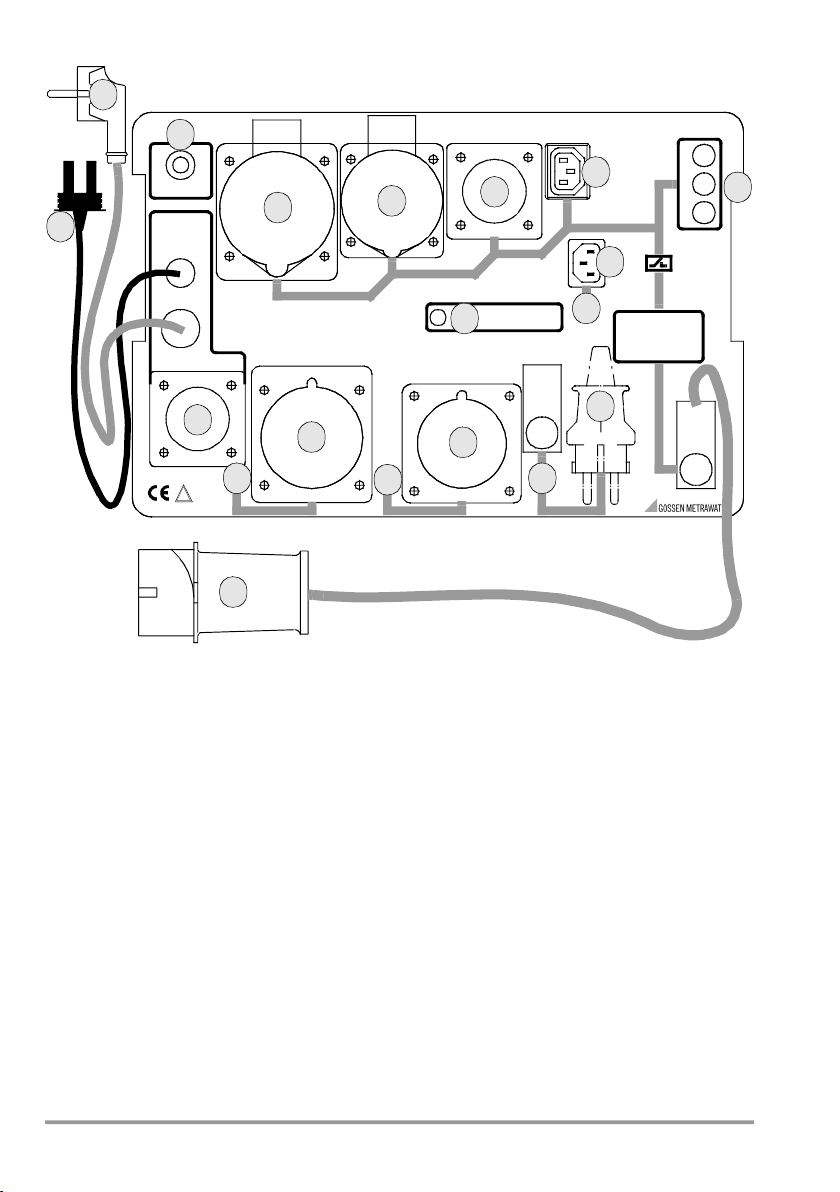

• The test adapter’s 16 A CEE 3P+N+PE (16)

plug may only be connected to 230/400 V

50 Hz mains power. In order to avoid unde-

sired shutdown of defective devices under

test, the electrical circuit for the device under

test should be separately fused.

• Before connecting the AT3-III E to the mains,

the test instrument must first be connected to

the AT3-III E.

Attention!

!Tests during which mains power is ap-

plied may only be selected with the func-

tion selector switch at the test instrument

after safety class I devices under test

have passed the protective conductor

test. If the protective conductor is defec-

tive (interruptions / reversed conductors),

line voltage may be present at the hous-

ing of a defective device under test, at the

earthing contacts of the test plugs (4 – 7)

and at the safety socket (15)!

• For REASONS OF SAFETY, the device under test

must be turned off before switching to

“MAINS” so that dangerous devices under

test (e.g. a circular saw) can only be switched

on intentionally.

•Measurement with line voltage:

Exposed parts may conduct dangerous touch

voltage during testing. Do not touch under

any circumstances! Use a special cover in

order to avoid touch contact.

Under certain circumstances, full mains dis-

connection at the device side may not occur

in the event of leakage current, or it may be

inadequate to meet the requirements of a

PRCD.

Work only at a protected workstation, i.e. use

enhanced touch protection, use a 30 mA

RCD and wear personal safety equipment

(PSE).

• Be prepared for the occurrence of unex-

pected voltages at devices under test (e.g.

due to charged capacitors).

• Before connecting the device under test to

the test adapter, subject it to a thorough

VISUAL INSPECTION first. Damaged devices

under test must be repaired prior to testing.

• Only extension cables which have been

plugged into the test outlets (1-4) at the test

adapter may be connected to the device

plugs (4- 7) at the test adapter.

• Due to test adapter design in accordance with

DIN VDE 0404, the “PE” contacts at the out-

lets (1-4) are only connected to the mains pro-

tective conductor when the test instrument

has been set for testing with mains power.