OM-06704 PA SERIES

PAGE B - 2 INSTALLATION

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

c. Compare the amperes, phase, voltage and

hertz indicated on the pump motor nameplate

to the ratings indicated for the control box.

d. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated. Note that the pump shaft rotates in

the required direction.

Only operate this pump in the direction in

dicated by the arrow on the pump body

and on the accompanying decal. Other

wise, the impeller could become loosened

from the shaft and seriously damage the

pump.

e. Check levels and lubricate as necessary. Re

fer to LUBRICATION in the Maintenance and

Repair Manual and perform duties as in

structed.

f. If the pump has been stored for more than 12

months, some of the components or lubri

cants may have exceeded their maximum

shelf life. These must be inspected or re

placed to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

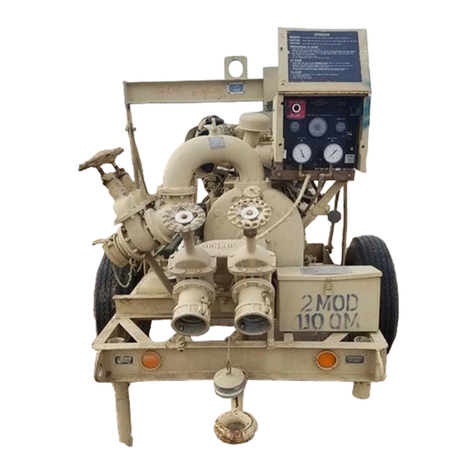

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

If the pump has been mounted on a

movable base, do not attempt to operate

the pump unless the unit is level. Be

sure the leveling stands are positioned

on a solid surface, and the wheels are

chocked.