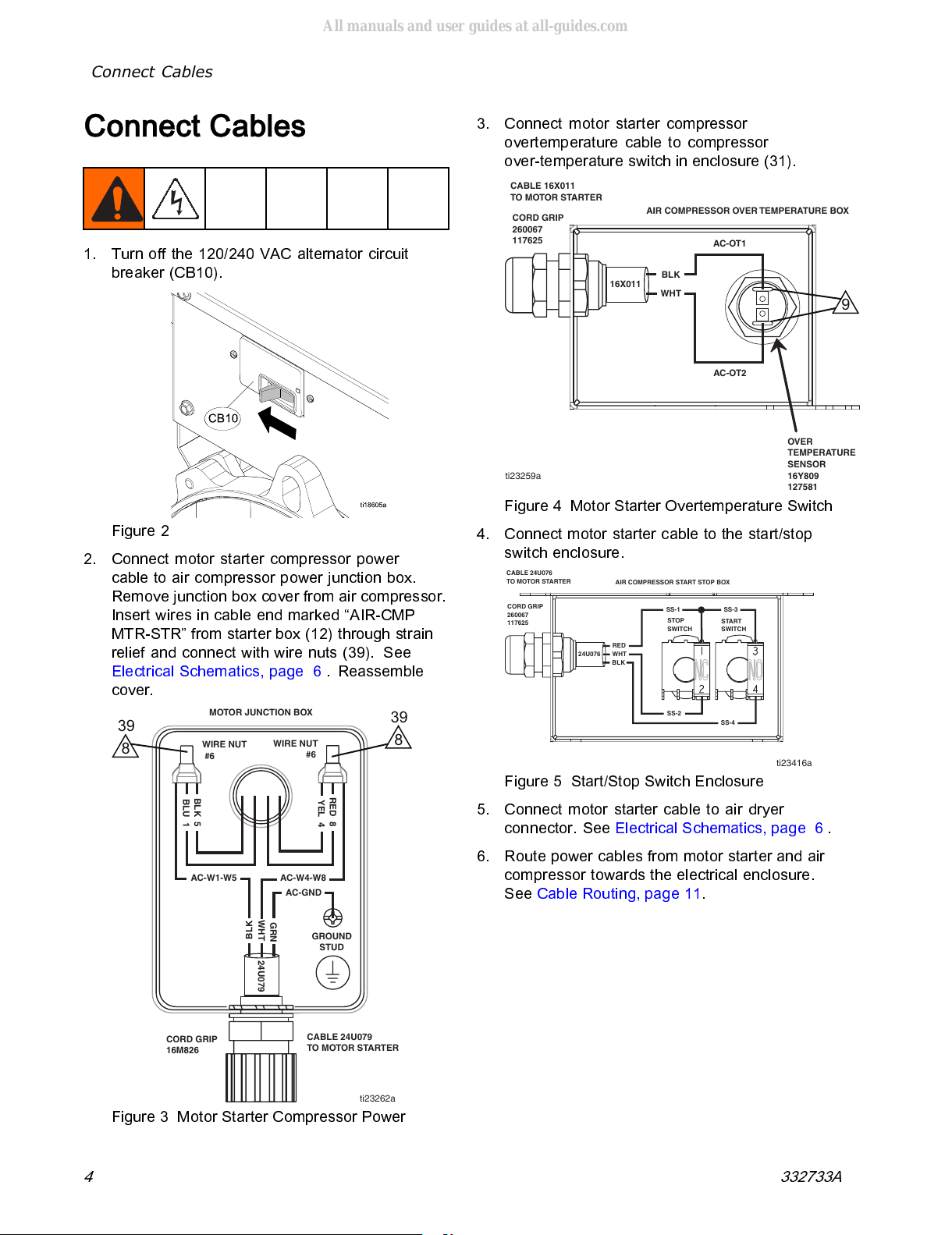

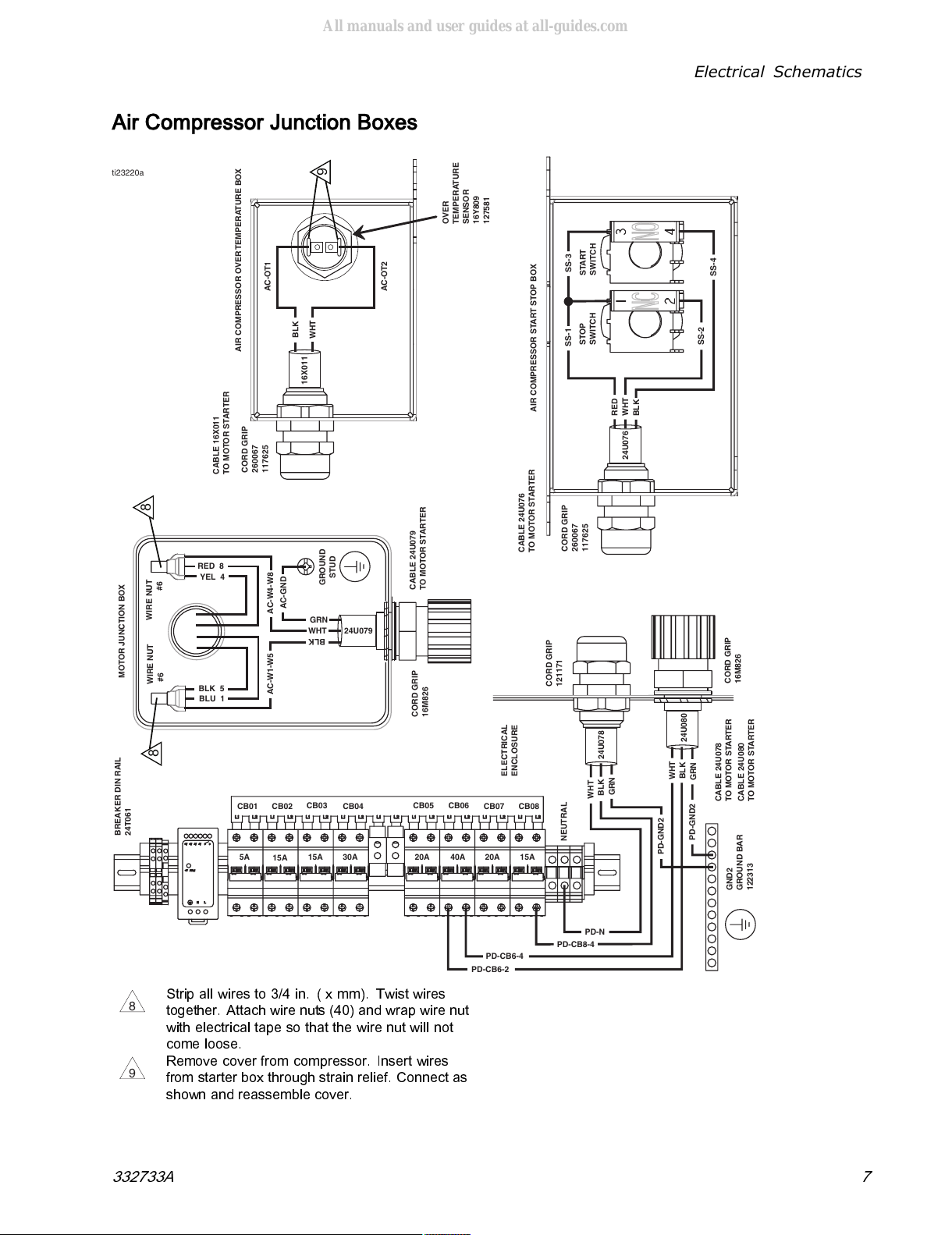

Install Air Compressor

Install Air Compressor

Reference parts illustration, Parts, page 9 .

1. Install air compressor frame (1) and air dryer

frames (2) on pallet with screws (723). eave

nuts and bolts loose.

Note

The fuel tank may need to be removed

to gain access to the frame mounting

screws.

2. Remove two existing nuts (N) from system and

secure frame (2) to system with nuts (N). Torque

to 40 ft-lbs (54 N•m).

Note

Shift or tilt the proportioner forward to

gain alignment.

3. Connect air compressor frame (1) and air dryer

frame (2) with frame (3).

4. Tighten all bolts and nuts.

5. Install end caps (37).

6. Install two motor brackets (29) with screws (31)

on top of frame (1).

Use lifting device to prevent personal injury

when lifting the compressor. Do not overlap

lifting straps over tubing or other fragile

components.

7. ift air compressor on top of brackets (29) and

secure to brackets with screws (30).

8. Install motor starter (10) to bracket (12) with

screws (14) and nuts (15). Attach to air

compressor frame (1) with screws (31).

9. Install switch box enclosure (17) on air control

panel with screws (18).

Install Air Dryer

Reference parts illustration, Parts, page 9 .

1. Connect air dryer outlet fittings and dump valve

(16), (24–268), and (40) and install on dryer as

shown.

2. ift air dryer onto frame (2) and align with fan

facing the engine. Install a nut (5) on the bottom

of each threaded rod to the end of the thread.

Thread rods (9) through nuts in bracket (2) and

secure with nuts pre-installed on rod.

3. Connect clamp bracket (8) to rods (9) with nuts

(5).

4. Connect elbow fitting (32), barbed fitting (33) and

rubber hose (34) to fitting. Secure hose (34) with

clamp (38) and route hose to drain pail.

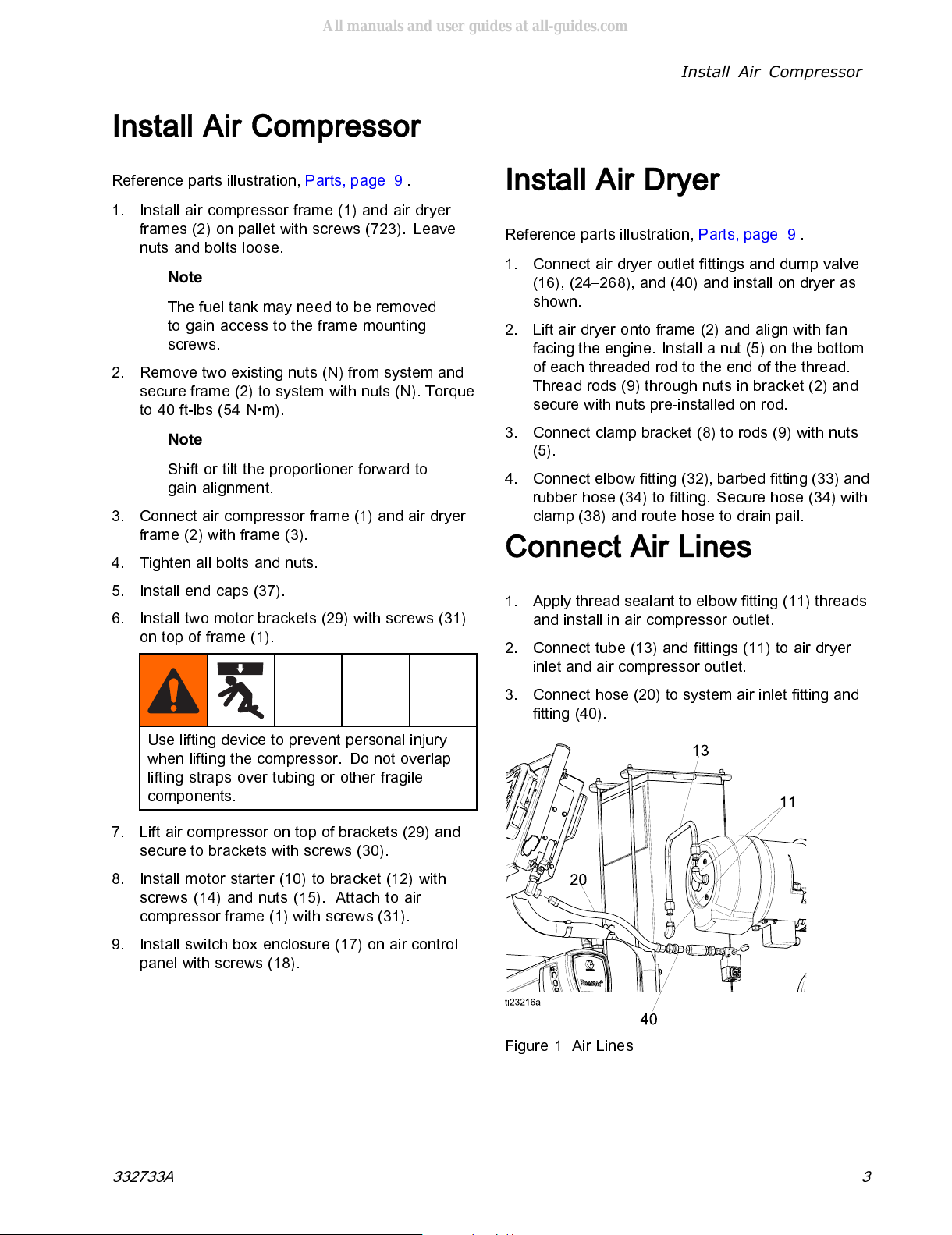

Connect Air Lines

1. Apply thread sealant to elbow fitting (11) threads

and install in air compressor outlet.

2. Connect tube (13) and fittings (11) to air dryer

inlet and air compressor outlet.

3. Connect hose (20) to system air inlet fitting and

fitting (40).

Figure 1 Air ines

332733A 3