Startup

3A6225A 9

Startup

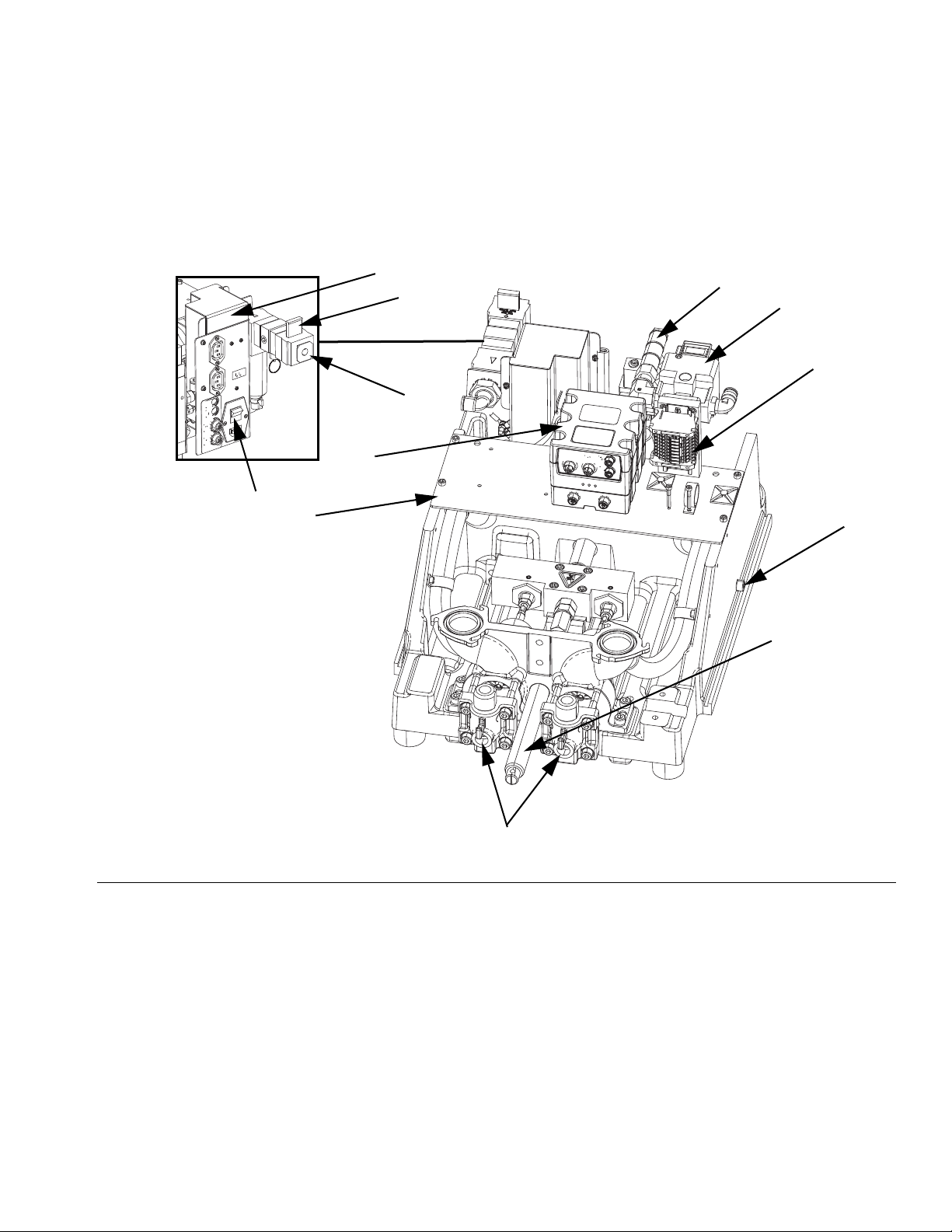

If the newly converted PR70f is not turned on, locate the

power switch (J) at the rear of the machine and turn the

power on. The Advanced Display Module (ADM) will

automatically turn on and begin to load.

With the air line connected to the machine at the air inlet

(K), slide up the system air pressure relief switch (L). It

is the yellow tab on the air inlet at the rear of the

machine. The hole in the tab should not be showing.

Using the Advanced Display

Module

When the main electrical power is turned on, the Graco

splash screen will be displayed on the ADM until com-

munication and initialization is complete.

The ADM will operate in any mode other than Disabled

(shown below). Press the Mode Select soft key to

change to another operating mode. Once you have

selected the desired mode, press the ADM’s Enter key

to accept it.

There are two types of screens on the ADM: Run and

Setup screens. The ADM starts in the Run screens. To

access the Setup screens, press . If the password

feature is enabled, you need to enter the password

when prompted to access the Setup screens. Use the

numeric keypad to enter the password, then press

.

Refer to the PR70f with Flow Control Operation - Main-

tenance manual for information about the available

screens. See Related Manuals on page 3.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the

work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and

burns.

NOTICE

To prevent damage to soft keys buttons, do not press

the buttons with sharp objects such as pens, plastic

cards, or fingernails.