Installation

Introduction

The

Second Color Kit is designed to increase existing

Road Lazer System capability by adding an additional

pump and supporting accessories. The Second Color

Kit can be added to an existing Road Lazer with one or

two pumps.

Pressure Relief Procedure

WARNING

INJECTION

HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally

. Fluid

under high pressure can be injected through the

skin and cause serious injury

. T

o reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

in

your sprayer manual whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tip.

1.

Flush the system. See

Flush System in manual

308–611.

2.

Relieve pressure. See

Pressure Relief Proce

-

dure

in manual 308–61

1.

General Instructions

The

following paragraphs provide instructions for

installing the Second Color Kit components on the

Road Lazer Striper

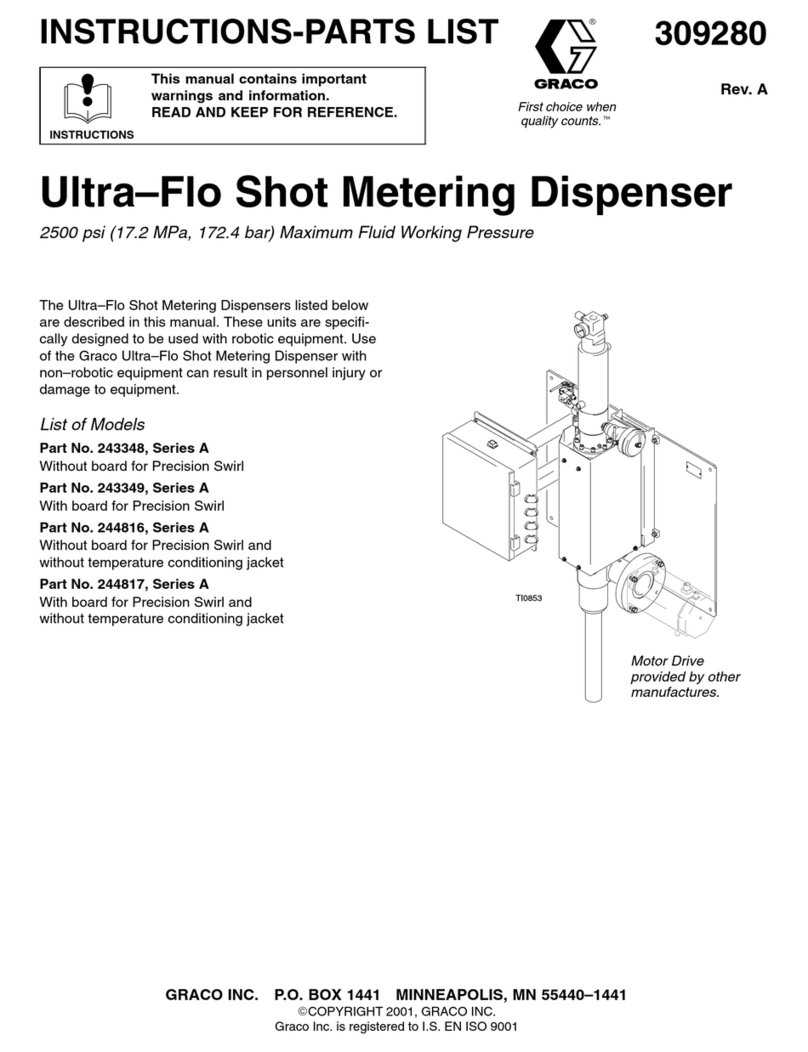

. Refer to Figs. 1 thru 4 for installa

-

tion. See Fig. 5 for parts list. The schematics on pages

10 and 1

1 provide additional detail and orientation in

-

formation for installation. Index numbers with an A are

kit parts. Other index numbers are parts for the Road

Lazer.

Installation of Pump, Fluid Filter, and

Paint Hose

1. See

Figs. 1 and 2. Install kit pump (A01) by pla

-

cing in open space in pump mount base (413) next

to installed pump. Attach with four capscrews

(A24) and four locknuts (A15).

2.

Attach fluid filter assembly (A02) to pump nip

-

ple (A23).

3.

See Fig. 3. Connect one end of coupled hose

(A38) to swivel union (A04) on fluid filter

. Route

hose along protection tube (5) to second gun

(341). Use tie straps (A37) to secure hose to tube.

4.

Remove spare pipe plug from second gun (341).

Attach hose to spare gun inlet using swivel union

(A04) and ball valve (A39).

Installation of Pump Hydraulic

Components

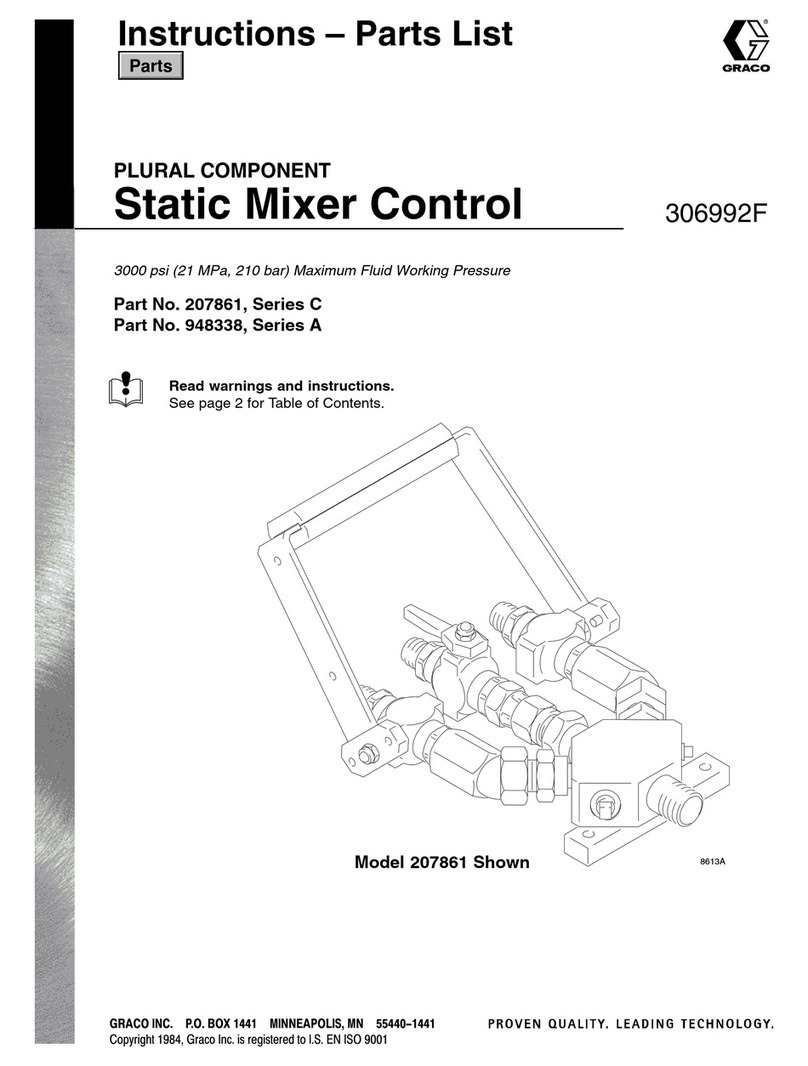

1. See

Fig. 4. Install flow regulator (A26) on valve

manifold (84).

2.

Remove pipe plug next to installed ball valve (91)

on top of manifold. Install kit ball valve (A27), pipe

elbow (A28), straight nipple (A30), and coupled

hose (A31).

3.

Route and attach hose to connection at bottom of

pump.

4.

Install hydraulic hose from top of pump to hydraulic

reservoir

. Remove existing pipe plug from street

tee (97) or elbow (102) on top of reservoir and

connect hose(A32).

Syphon Setup For 2 Pump Configuration

See

Figs. 1 and 3. Attach coupled hose (A20) from

paint syphon to inlet on pump using fitting (A13)

and clamp (A21).

One color setup:

Attach both hoses to one suction

tube.

Two color setup:

Attach each hose to a single suc

-

tion tube.

Syphon Setup For 3 Pump Configuration

See

Figs. 2 and 3. For 3 pump configuration, set

-

up syphons as shown in Figs. 2 and 3.

Complete Installation

WARNING

For

safe operation of this equipment , see

manual 308–61

1 for important warnings and

instructions.

1.

After installing kit, flush system to prepare for

painting. See

Flush System in manual 308–61

1.