6 307933

Installation

Supplied Components

Refer to Fig. 2 for a typical installation of an air-

assisted system.

WARNING

A red-handled bleed-type master air valve (42) and

a fluid drain valve (4) are supplied in your system.

These accessories help reduce the risk of serious

injury, including fluid injection and splashing of fluid

in the eyes or on the skin, and injury from moving

parts if you are adjusting or repairing the pump.

The red-handled bleed-type master air valve re-

lieves air trapped between this valve and the pump

after the air is shut off. Trapped air can cause the

pump to cycle unexpectedly. Locate the valve close

to the pump.

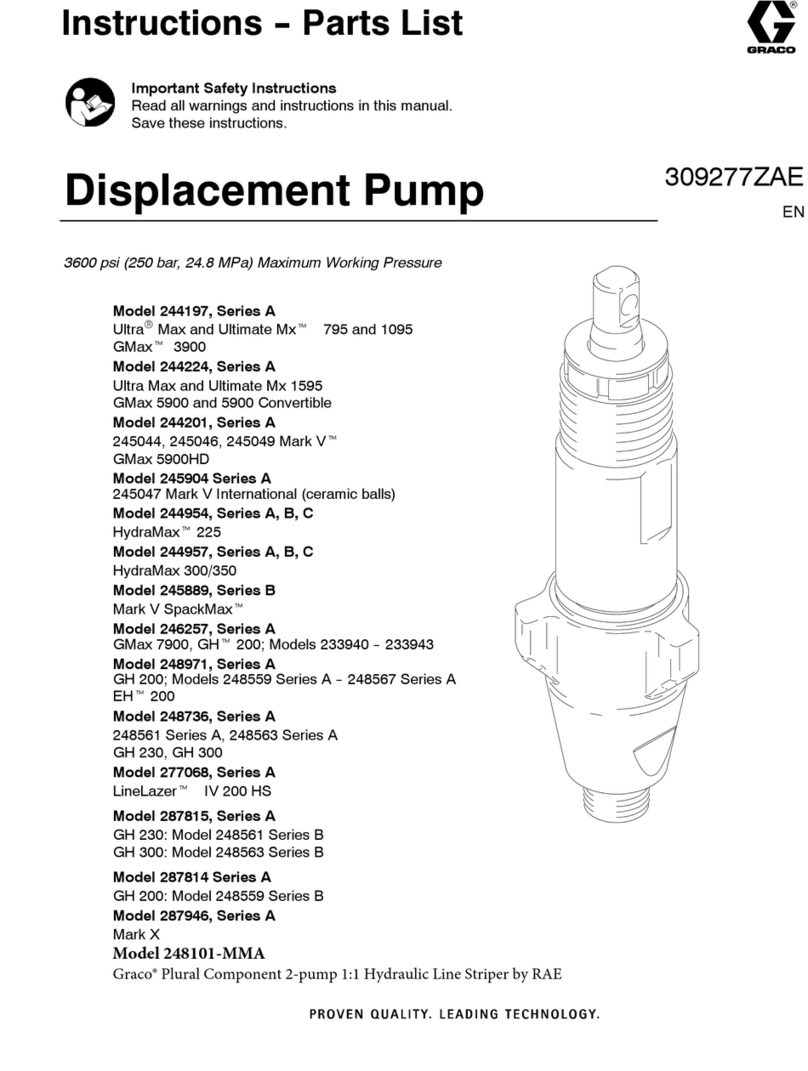

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may not be

sufficient.

DThe red-handled bleed-type master air valve

(42) is required in your system to relieve air trapped

between it and the air motor when the valve is

closed (see the WARNING above). Be sure the

bleed valve is easily accessible from the pump, and

is located downstream from the air regulator.

DThe air regulator (2) controls pump speed and

outlet pressure by adjusting the air pressure to the

pump. Locate the regulator close to the pump, but

upstream from the red-handled bleed-type master

air valve (42).

DThe air manifold (43) has a swivel air inlet. It

mounts to the cart, and provides ports for connect-

ing lines to air-powered accessories.

DThe fluid filter (5) includes a 60 mesh (250 mi-

cron) stainless steel element to filter particles from

the fluid as it leaves the pump.

DThe fluid drain valve (4) is required in your sys-

tem to relieve fluid pressure in the hose and gun

(see the WARNING above).

DThe suction hose (16) and tube (17) allow the

pump to draw fluid from a 200 liter (55 gallon) pail.

System Accessories

Air and Fluid Hoses

Be sure all air hoses (B, K) and fluid hoses (G) are

properly sized and pressure-rated for your system.

Use only electrically conductive hoses.

1. Connect one end of the fluid line (G) to the filter

outlet swivel. Connect a fluid hose to each gun (H).

Install a fluid shutoff valve (P) at each gun drop.

Do not install the spray tip in the gun yet.

2. Close the red-handled bleed valve (42) and air

regulator (2). Connect the air hose (B) to the

swivel inlet of the air manifold (J). In air-assisted

systems, connect an air supply line (K) with regula-

tor (L) and shutoff valve (M) to the air inlet of each

gun.

Air Line Accessories

1. Install an air line filter (A) in the main air line, to

remove harmful dirt and moisture from the com-

pressed air supply.

2. Install a second bleed valve (Q) in the main air

line, to isolate the accessories for servicing.

3. Install a drain valve (W) at the bottom of each air

line drop, to drain off moisture.

4. To provide automatic lubrication of the air motor,

install an air line lubricator (C) downstream from

the red-handled bleed-type master air valve (42).

5. Install a pump runaway valve (F). The runaway

valve will automatically shut off the air to the pump

if the pump starts running too fast. A pump that

runs too fast can be seriously damaged.