4 – 44 Operating & Installation Instructions EN KLF5/KLF7/KLF15/KLF25 Date 24.08.2023 Version 7.0

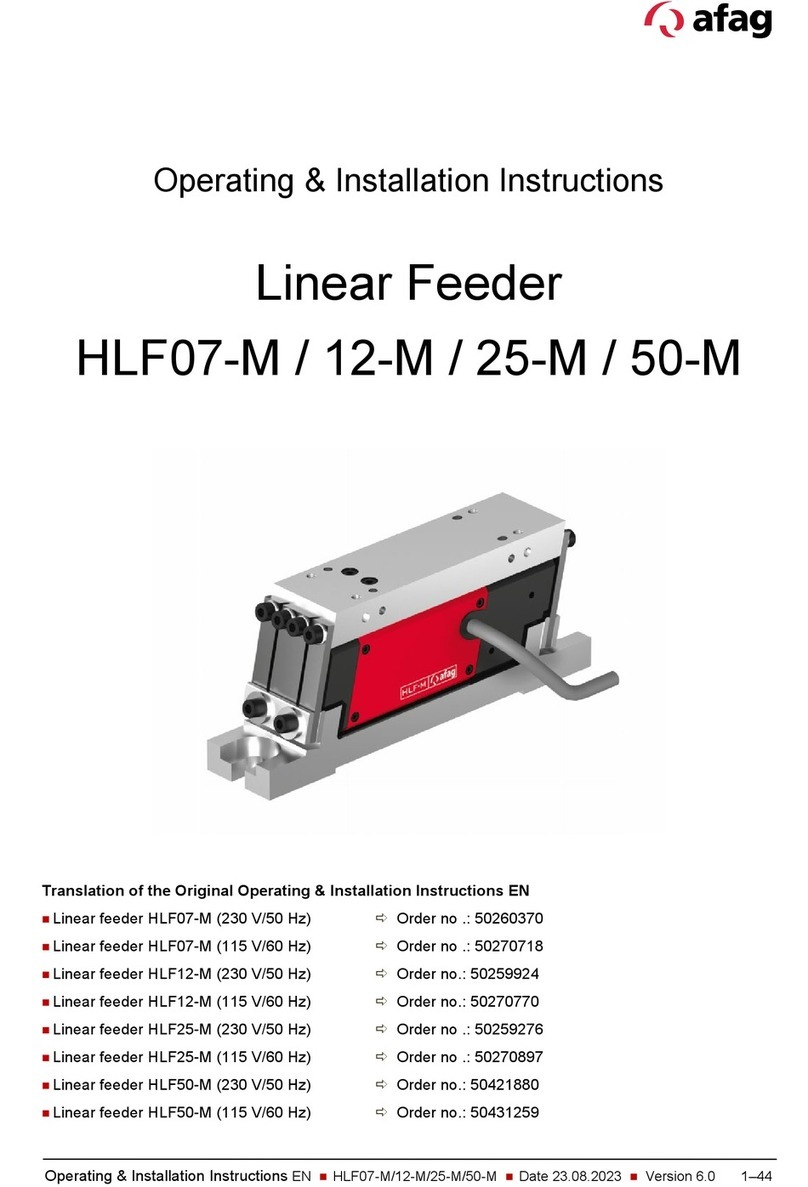

5Design and description ....................................................................................... 22

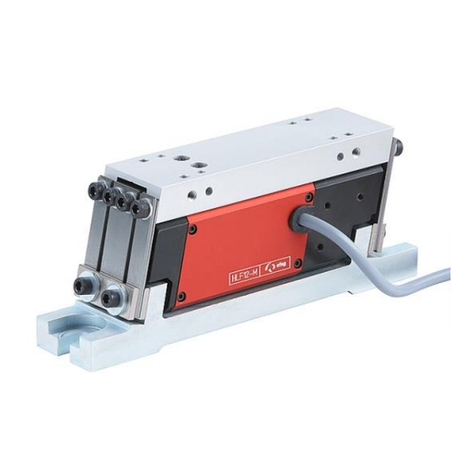

5.1 Structure of the KLF ................................................................................... 22

5.2 Description of the KLF ................................................................................ 22

6Installation, assembly and setting ..................................................................... 23

6.1 Safety instructions ...................................................................................... 23

6.2 Assembly .................................................................................................... 24

6.2.1 Tightening torques................................................................................ 24

6.2.2 Fastening the module........................................................................... 24

6.2.3 Assembly of the conveyor rail .............................................................. 25

6.2.4 Assembly of two conveyor rails............................................................ 26

6.2.5 Assembly of divided conveyor rails ...................................................... 27

6.3 Electrical connection................................................................................... 28

6.4 Settings....................................................................................................... 29

6.4.1 Design of the conveyor rails................................................................. 29

6.4.2 Adjust balance of weights .................................................................... 30

6.4.3 Natural frequency fine adjustment ....................................................... 32

6.4.4 Adjust air gap ....................................................................................... 34

7Operation .............................................................................................................. 35

7.1 Safety instructions for commissioning ........................................................ 35

7.2 Preparatory activities for commissioning.................................................... 35

7.3 Commissioning of the modules .................................................................. 35

8Fault elimination................................................................................................... 36

8.1 Safety instructions ...................................................................................... 36

8.2 Fault causes and remedy ........................................................................... 36

9Maintenance and repair....................................................................................... 39

9.1 General notes ............................................................................................. 39

9.2 Safety instructions ...................................................................................... 39

9.3 Maintenance activities and maintenance intervals..................................... 40

9.3.1Overview of the maintenance points .................................................... 40

9.3.2 Check leaf springs for wear and oxidation ........................................... 40

9.3.3 Check spring setting behaviour............................................................ 41

9.3.4 Remove leaf springs ............................................................................ 41

9.3.5 Further maintenance ............................................................................ 41

9.4 Spare and wear parts lists, repairs............................................................. 42

9.4.1 Spare parts........................................................................................... 42

9.4.2 Wear parts............................................................................................ 42

10 Decommissioning and disposal ......................................................................... 43

10.1 Safety instructions ...................................................................................... 43

10.2 Decommissioning ....................................................................................... 43

10.3 Disposal...................................................................................................... 43