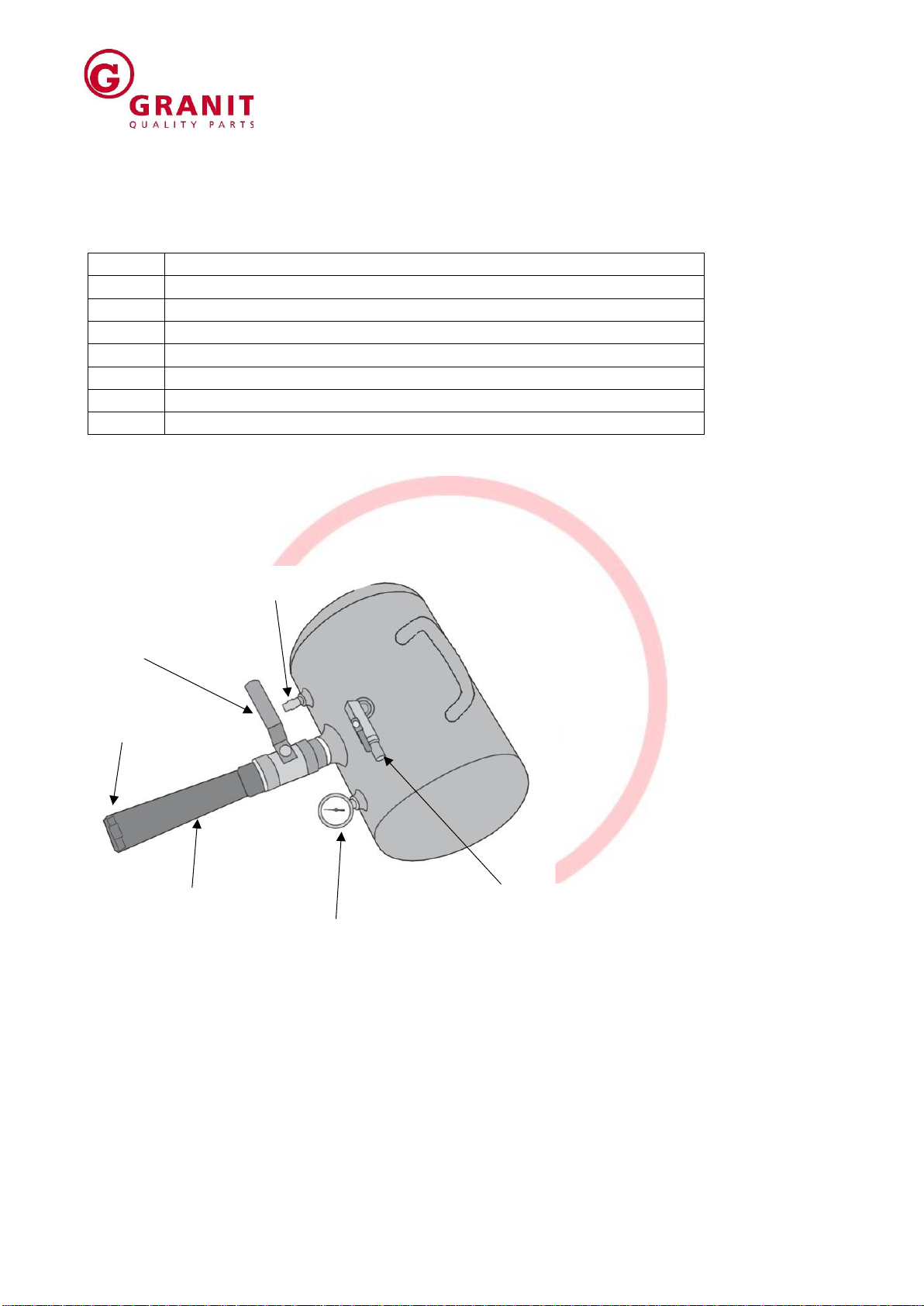

Booster Operating Instructions

810000082/11139940

9

Eye protection. There is a risk of dust, mounting paste or other foreign objects being

ejected by the airflow and causing serious injury to persons. Therefore safety glasses

must always be worn.

Hazards to others

For the protection of persons located close to the work area, the distance between the point

of use and unaffected third parties must be at least 10 m. If it is not possible to comply with

distance, other methods of separation must be provided.

Tyre

ATTENTION: When the edge of the tyre jumps into the final position, it does so with

a large amount of energy and at high speed.

The general protective measures for workshops and tyre fitting and filling devices should be

applied.

for split rims: please make sure that the locking ring is fitted and fixed correctly.

When filling: Do not fill the tyre beyond the recommended permitted pressure; when filling

use a safety cage for tyres.

Damage: Before starting the filling of the tyre please check it carefully for damage.

Unauthorised use

The booster must not be used for example for blowing away dust.

ATTENTION: Never direct the device at persons, animals or other objects. There is a

risk of severe injuries and property damage.

ATTENTION: The tyres and rims must not be cleaned with highly flammable liquids,

before being filled with the booster.

9. Maintenance and storage

Maintenance:

The BOOSTER must be checked for damage regularly, in line with the environment in which

it is used. The pressure tank must be subjected to the required statutory inspections. Any

damaged parts must be replaced by original spare parts prior to use. Please take care not to

damage the tapering filling nozzle. Both maintenance and service work must only be done

with the container empty.

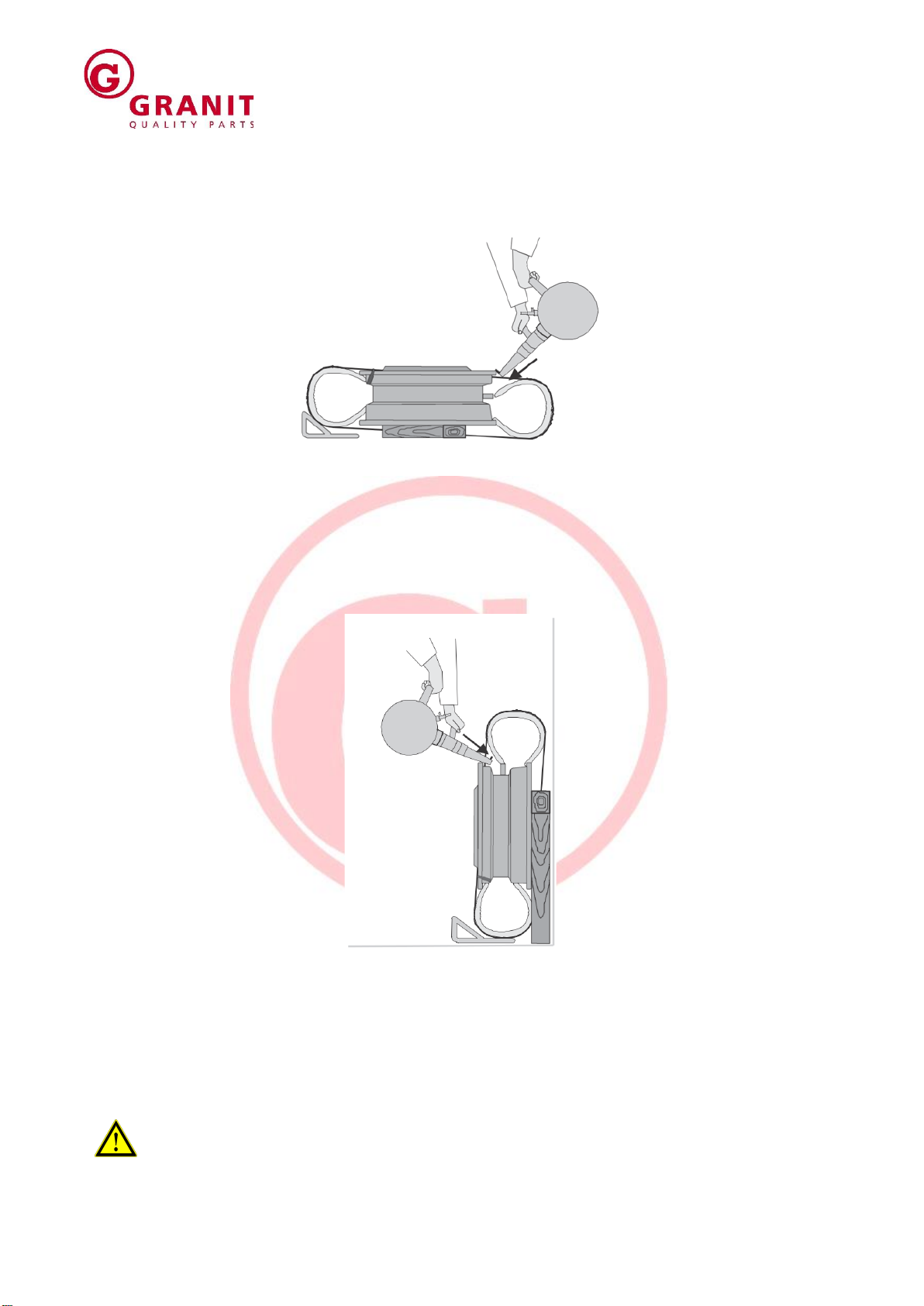

Storage:

The BOOSTER must always be stored with the main valve opened and the tapering nozzle

pointing downwards. The best solution is to hang up the BOOSTER on a suitably load-bearing

wall hook in a dry location. For both maintenance work and storage, the ball valve must be

opened slowly, so that can escape slowly out of the container. When doing so the nozzle

should not be held towards the corner of a room or similar, to prevent staring up dirt particles.