Introduction

6

1 Introduction

1.4 Boiler Components

1.4.1 Burner. The burner is supplied

factory-fitted to the boiler. All burners

are supplied with factory default

settings. During commissioning each

burner parameter will need to be

checked (see Section 8), and adjusted

if necessary as the flue length can have

a significant effect on the boiler

performance. Refer to commissioning in

Section 9.

The Burner is equipped with a self

cleaning device to prevent a build up of

ash and clinker in the burner brazier.

The burner output is determined by the

feed / pause times of the pellet feed

auger supplying the burner. See Section

8 for full burner operation details.

1.4.2 Boiler. The SPIRA condensing

boiler is supplied with a combined

primary and secondary heat-exchanger.

Both heat exchangers are equipped

with a self cleaning system.

1.4.3 Boiler controls. The set-point

temperature of the boiler is user

adjustable via two push buttons on the

burner control panel - see Section 8.4

for details.

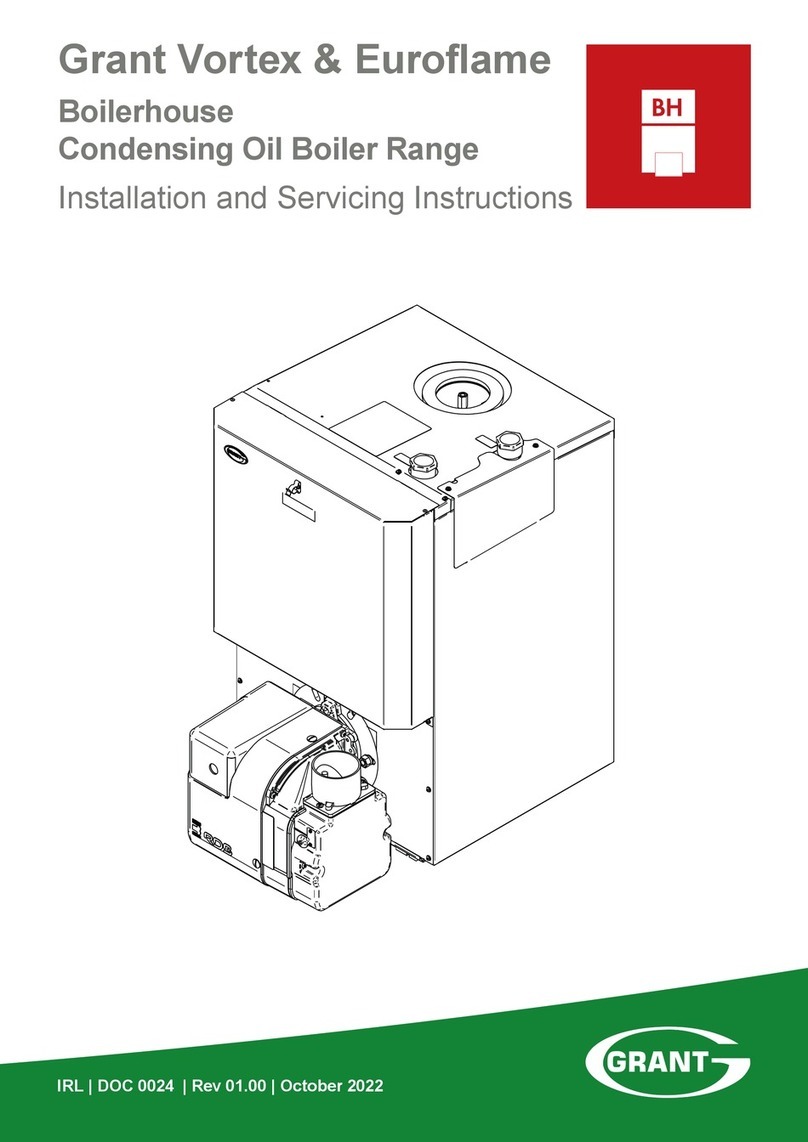

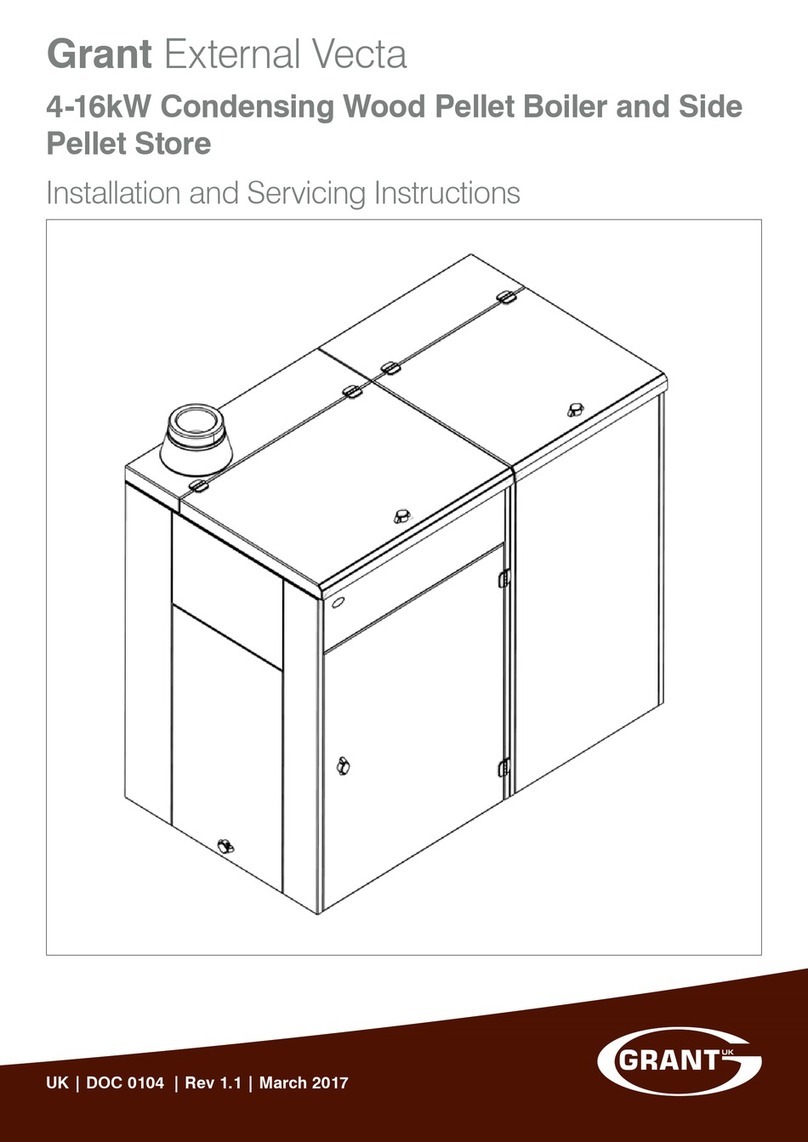

The boiler control panel (See Figure 1.1.)

is located at the top of the boiler and is

fitted with three controls, as follows:

ON/STAND-BY switch – to switch off

the burner when required, by

interrupting the switched live supply to

the burner. This switch does not isolate

the electrical supply to the burner.

OVERHEAT thermostat - this allows

the boiler to be used on a sealed

central heating system and will

automatically switch off the boiler if the

pre-set temperature of 110°C is

exceeded.

CLEANING switch - when pressed

and held in the TEST position, it allows

the cleaning system to be manually

operated and tested. When released it

will automatically return to the default

AUTO position to allow the boiler

cleaning system to perform

automatically. Only operate the cleaning

switch when the boiler is in ‘WAIT

BOILER THERMOSTAT’.

1.4.4 Boiler Pellet Hoppers. All single

boilers (Spira 6-26 and 9-26 models)

come with a pellet hopper. Two sizes of

hopper are available for use with single

boilers, as follows:

• 110 kg hopper – for storing a

maximum of 110kg

(≈170 litres) of wood pellets

• 200kg hopper – for storing a

maximum of 200kg

(≈308 Litres) of wood pellets.

There are two versions of both the

110kg and 200kg pellet hopper

available for use with a single boiler:

Left hand hopper – to be positioned

on the left hand side of the boiler. This

is the ‘standard’ option and will be

automatically supplied with the boiler

unless specified otherwise.

Right hand hopper – to be positioned

on the right hand side of the boiler. This

is the ‘non-standard’ option and must

be specified when ordering the boiler.

Both hoppers are supplied with a single

1.2m pellet feed auger, to be fitted to

the hopper on site by the installer.

All ‘double boiler’ installations (Spira

12-52, 15-62 and 18-72 models) come

with one 'double' hopper to feed both

boilers. This hopper is positioned

between the two boilers and stores a

maximum of 140 kg (≈215 litres).

ALL the Grant pellet hoppers are for

indoor use only and must be

positioned in a dry environment.

Hopper contents switch

All hoppers are fitted with a contents

switch. This detects when the level of

pellets in the hopper falls to a pre-set

minimum value and triggers the

operation of either a bulk store auger,

or vacuum system, to delivery pellets

from the bulk pellet store.

If no bulk store is used, the contents

switch will stop the burner operating

when the minimum pellet level is

reached.

Topping up the hopper with more

pellets will automatically operate the

contents switch and the burner will

restart (if there is a demand for the

boiler to run).

The minimum quantity of pellets

required to restart the boiler is 20kg for

the single boiler hoppers and 3kg for

the double boiler hoppers.

All boiler pellet hoppers are for

indoor use only and MUST be

positioned in a dry environment free

from dampness. They must be located

on the same floor level as the boiler, or

boilers, they are supplying.

All hoppers are mounted on four

castors (with the two front castors

lockable) to allow it to be easily moved

when required. Allow sufficient area in

front of the hopper for it to be moved

out and away from the boiler(s) during

servicing.

The electrical connections to the

boiler(s) are all made to the 4-way

electrical plug on one of the three

factory-fitted ‘flying leads’ at the rear of

the hopper. Refer to Section 7 for

details.

After the burner has been switched

off (either manually by the switch on

the control panel, or automatically by

the boiler control stat, or the heating

system controls) the burner needs to

burn-down the remaining pellets in

the brazier. Do not open the front

combustion chamber access door

until the burner display reads “WAIT

BOILER THERMOSTAT”.

!WARNING

Figure 1-1: Boiler control panel