Raypak DELTA LIMITED 989B-2339B User manual

Other Raypak Boiler manuals

Raypak

Raypak Xtherm 1005 Setup guide

Raypak

Raypak 0090B 0135B User manual

Raypak

Raypak Commercial Space Heating and Domestic Water User manual

Raypak

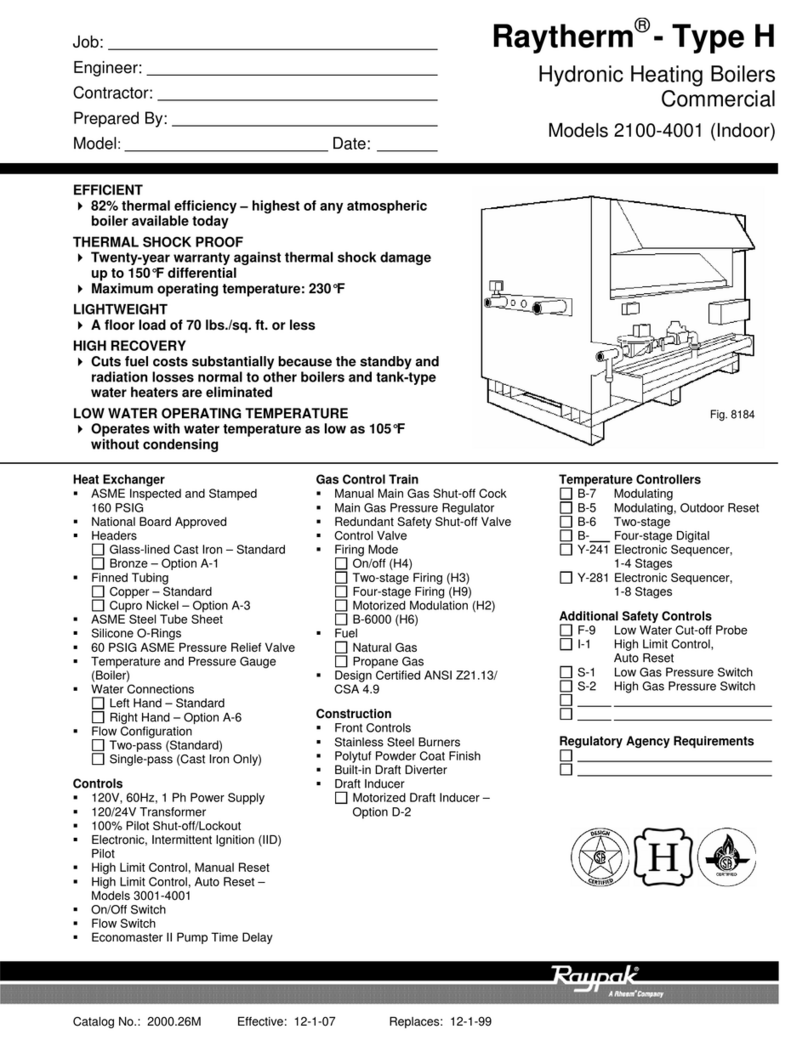

Raypak Raytherm H-2100 User manual

Raypak

Raypak Xtherm 1505A Manual

Raypak

Raypak XFyre 300A Manual

Raypak

Raypak 0133-4001 User manual

Raypak

Raypak RAYTHERM 0042B Manual

Raypak

Raypak 2503 Manual

Raypak

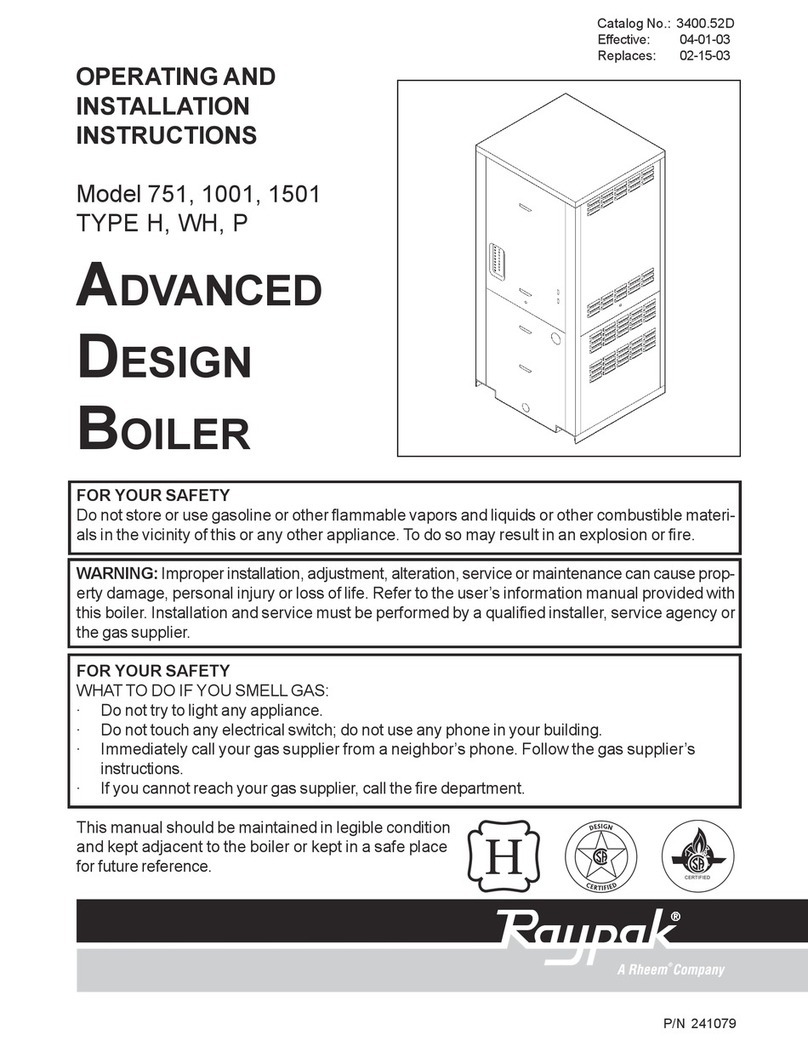

Raypak 1001 Specification sheet

Raypak

Raypak 88AR-398A Manual

Raypak

Raypak RAYTHERM 133 User manual

Raypak

Raypak XPAK 120 Manual

Raypak

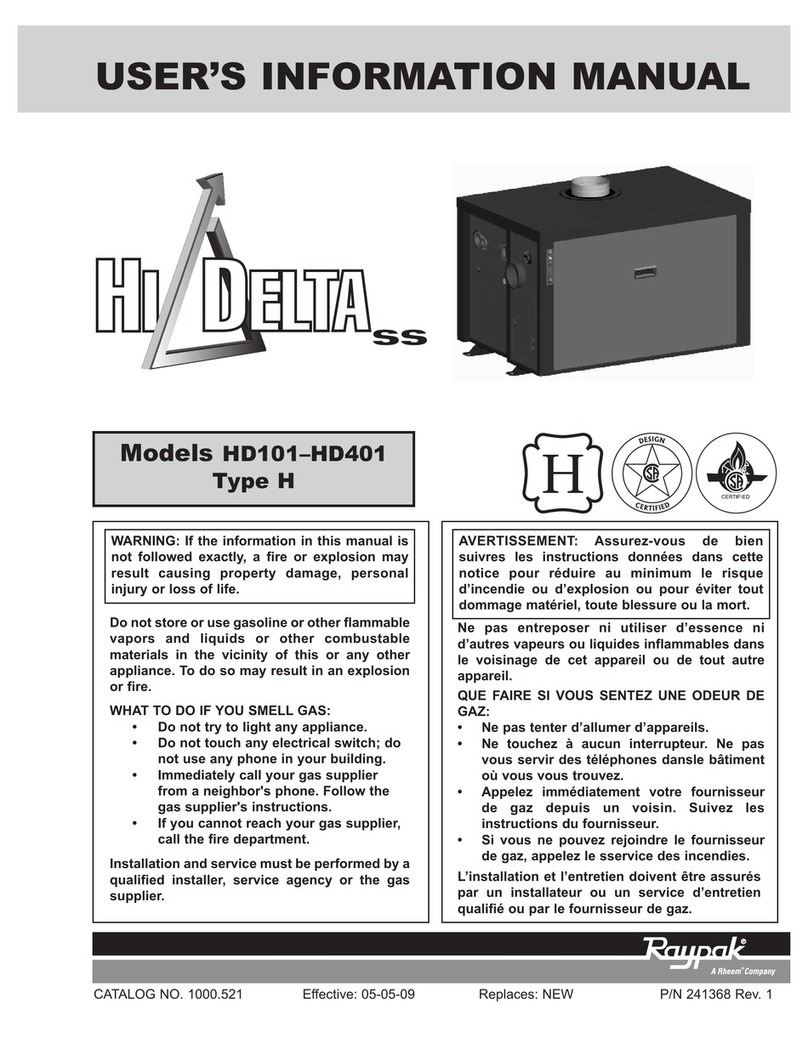

Raypak HI DELTA HD101 THRU 2342B Guide

Raypak

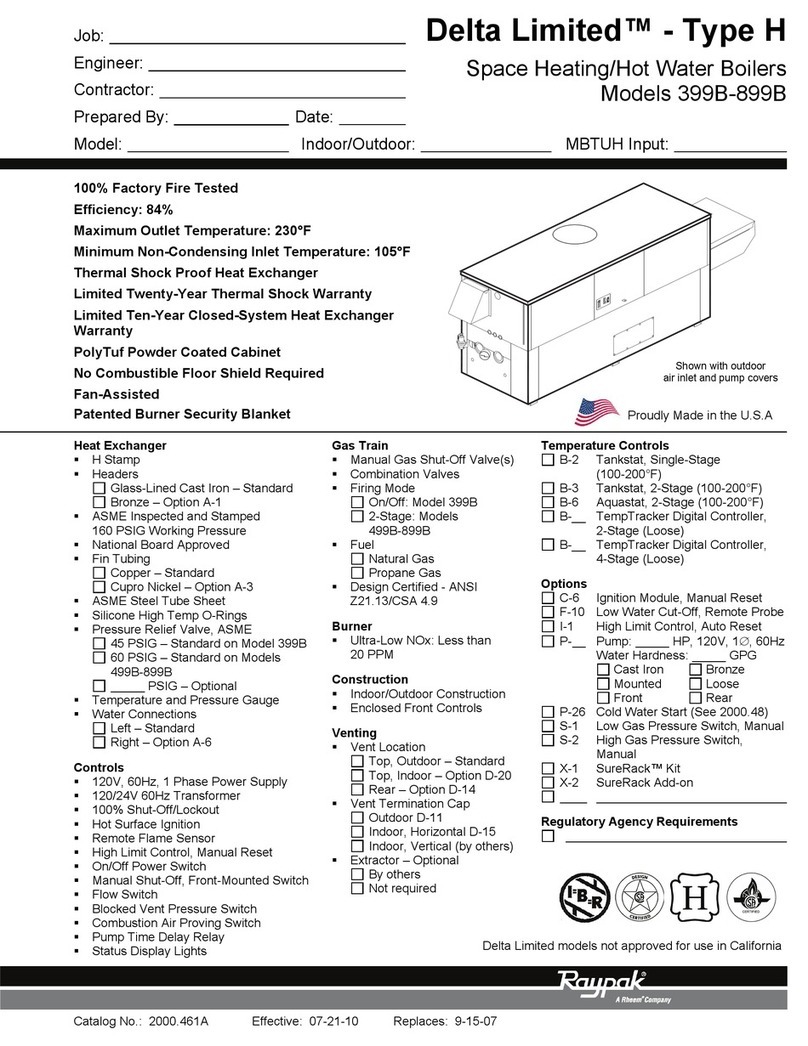

Raypak DEL TA LIMITED 399B User manual

Raypak

Raypak 503-2003 User manual

Raypak

Raypak 180B User manual

Raypak

Raypak RAYTHERM 133-4001 Manual

Raypak

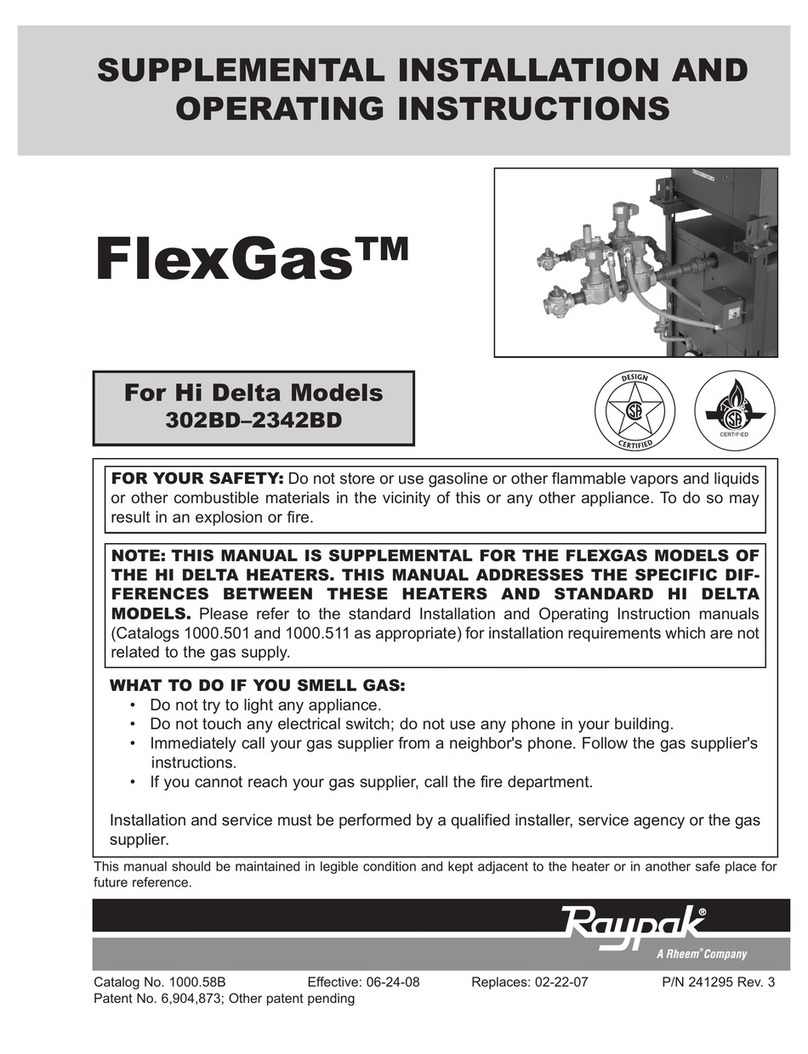

Raypak FlexGas 302BD-2342BD User manual

Raypak

Raypak 503-2003 Manual

Popular Boiler manuals by other brands

Vaillant

Vaillant uniSTOR VIH SW GB 500 BES operating instructions

Radijator

Radijator BIO max 23.1 instruction manual

Brunner

Brunner BSV 20 Instructions for use

Buderus

Buderus Logamax GB062-24 KDE H V2 Service manual

Potterton

Potterton 50e Installation and Servicing Manual

UTICA BOILERS

UTICA BOILERS TriFire Assembly instructions

Joannes

Joannes LADY Series Installation and maintenance manual

ECR International

ECR International UB90-125 Installation, operation & maintenance manual

Froling

Froling P4 Pellet 8 - 105 installation instructions

Froling

Froling FHG Turbo 3000 operating instructions

U.S. Boiler Company

U.S. Boiler Company K2 operating instructions

Henrad

Henrad C95 FF user guide

NeOvo

NeOvo EcoNox EF 36 user guide

Potterton

Potterton PROMAX SL 12 user guide

Eco Hometec

Eco Hometec EC 25 COMPACT Technical manual

Viessmann

Viessmann VITODENS 200 Operating instructions and user's information manual

Baxi

Baxi Prime 1.24 installation manual

REXNOVA

REXNOVA ISA 20 BITHERMAL Installation, use and maintenance manual