Section 3: InstallationPage 6

3 INSTALLATION

3.1 GENERAL

This section gives details of the installation process for the Grant

Combined volumiser/low loss header with backup immersion

heater.

These installation instructions must be read in conjunction with

the Grant Aerona³ air source heat pump installation instructions

(provided with the heat pump).

Before starting any installation work on the Grant Aerona³ air

source heat pump and volumiser/low loss header, please read the

Health and Safety information given in Section 14 of the Aerona³

Installation Instructions.

3.2 REGULATIONS AND STANDARDS

The installation of the Grant Aerona³ air source heat pump and

the volumiser/low loss header must be in accordance with the

following recommendations, as applicable:

• Building Regulations for England and Wales, and Building

Standards for Scotland

• Local Bylaws (check with the Local Authority for the area)

• Water Supply (Water Fittings) Regulations 1999

• MCS Installer Standards (if applying for the Renewable Heat

Incentive)

• MIS3005 Requirements for contractors undertaking the

supply, design, installation, set to work, commissioning and

handover of microgeneration heat pump systems.

• MCS020 MCS Planning Standard

The installation should also be in accordance with the latest

edition of the following standards and Codes of Practice:

• BS7671 and amendments

• BS EN 12831

3.3 LOCATION

The Grant Combined volumiser/low loss header can be mounted

on any suitable wall surface capable of carrying the weight of the

unit when full of water and where the required clearances can be

achieved.

The unit MUST be installed vertically, with the immersion heater at

the top, as shown in Figure 2-1.

It MUST only be installed inside a property, and not located

externally, as it not designed to be weatherproof.

! NOTE !

The Grant volumiser/low loss header MUST NOT be

installed externally.

3.4 CLEARANCES

The Grant Combined volumiser/low loss header must be installed

such that adequate clearance is available for maintenance. In

particular, a suitable clearance of 300mm must be available

immediately above the unit to allow the removal and replacement

of the electric immersion heater.

Suitable clearance should also be allowed on the right-hand side

of the volumiser/header for access to, and the use of, the air

vent, drain cock, and any system isolating valves, as and when

required.

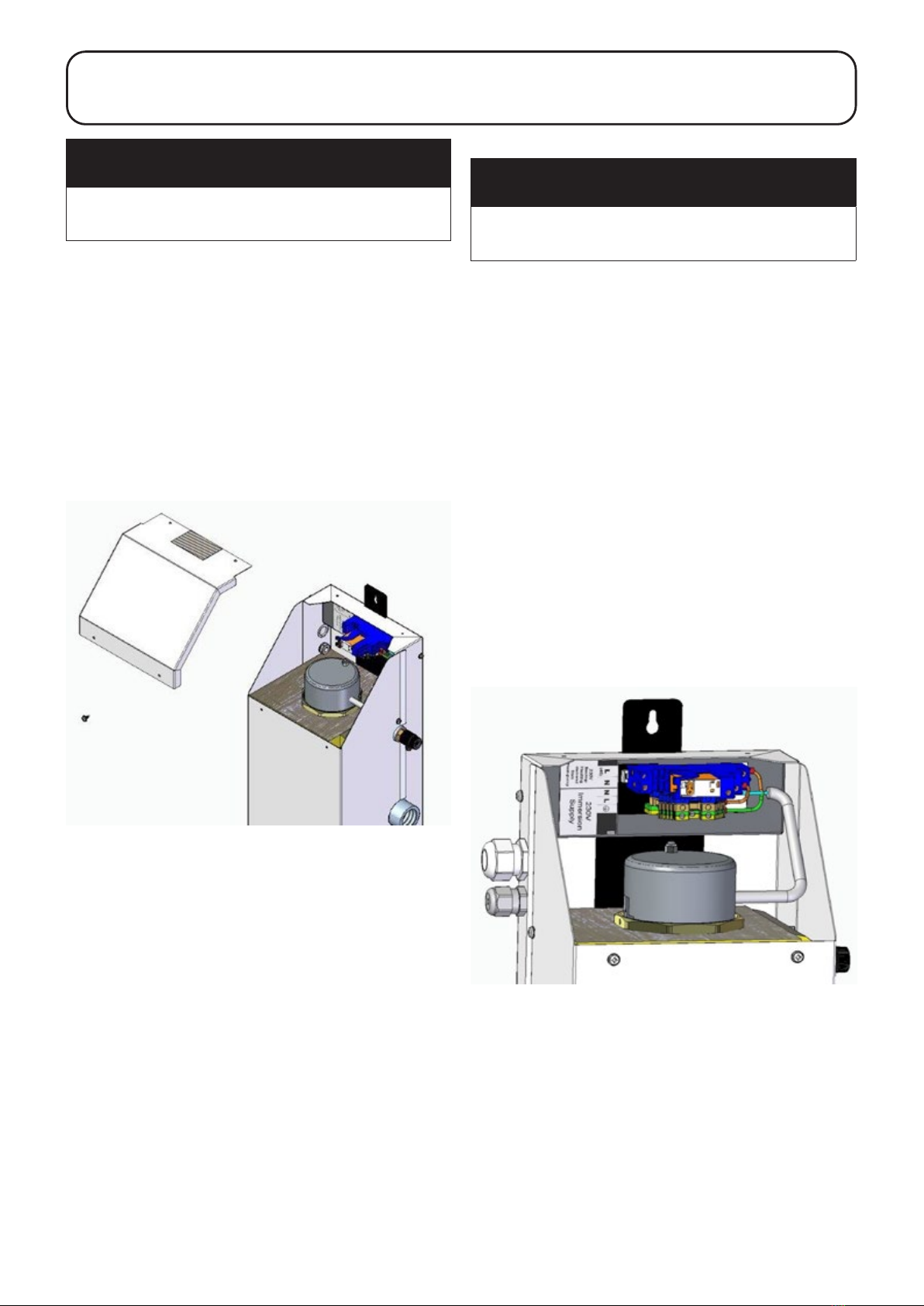

3.5 UNPACKING

The Grant Combined volumiser/low loss header is supplied

wrapped in bubble wrap with a separate kit of components

in a plastic bag located inside the top cover. Refer to list of

components given in Section 1.3 of these Instructions.

! NOTE !

Take care if cutting the bubble wrap with a knife not to

damage the volumiser/low loss header casing immediately

beneath.

3.6 INSTALLATION PROCEDURE

To install the Grant Volumiser/Low Loss Header:

1. Using a suitable thread sealant, t the ⅜” x ¼” reducing bush

into the ⅜” socket at the top of the right-hand side of the

volumiser/header and then t the ⅜” manual air vent into the

reducing socket. Refer to Figure 2-1. Position the air vent

such that the outlet is pointing downwards.

2. Again, using a suitable thread sealant, t the drain cock into

the ½” socket at the bottom of the right-hand side of the

header/volumiser. Refer to Figure 2-1. Position the drain cock

such that the outlet is facing downwards.

3. Position the volumiser/header with the back against the wall

on which it is to be mounted and mark the two xing centres

from both the top and bottom xing brackets.

4. Note that when lled with water, the volumiser/header will

weight 30kg. Ensure that the wall concerned is structurally

capable of carrying this weight.

5. Drill the wall to take suitable wall xings (not supplied) for

the type of wall construction and the weight of the volumiser/

header when full of water and t the wall xings.

6. Re-position the volumiser/header against the wall, align the

holes in the top and bottom xing brackets with the two wall

xings, and secure the header/volumiser to the wall with

screws.

! WARNING !

The immersion heater must NOT be used unless it is fully

immersed in water.

Always ensure that the volumiser/low loss header is full of

water BEFORE switching on the electrical supply.

3.7 HEAT PUMP FLOW AND RETURN

CONNECTIONS

The heat pump ow and return connections can be made to either

the right-hand or left-hand connections of the Grant Combined

volumiser/low loss header, but BOTH connections must be made

to the same side. Refer to Figures 3-1 and 3-2 for connection

details.

A second heat pump can also be connected to the volumiser/

header, but it must be connected to the same side as the rst heat

pump.

This second heat pump will operate as a ‘supplementary’ unit

controlled from the other ‘lead’ heat pump. Refer to Section 5 of

these instructions for the required parameter settings for both heat

pumps for this control conguration.

All unused connections should be sealed using the brass blanking

plugs provided.