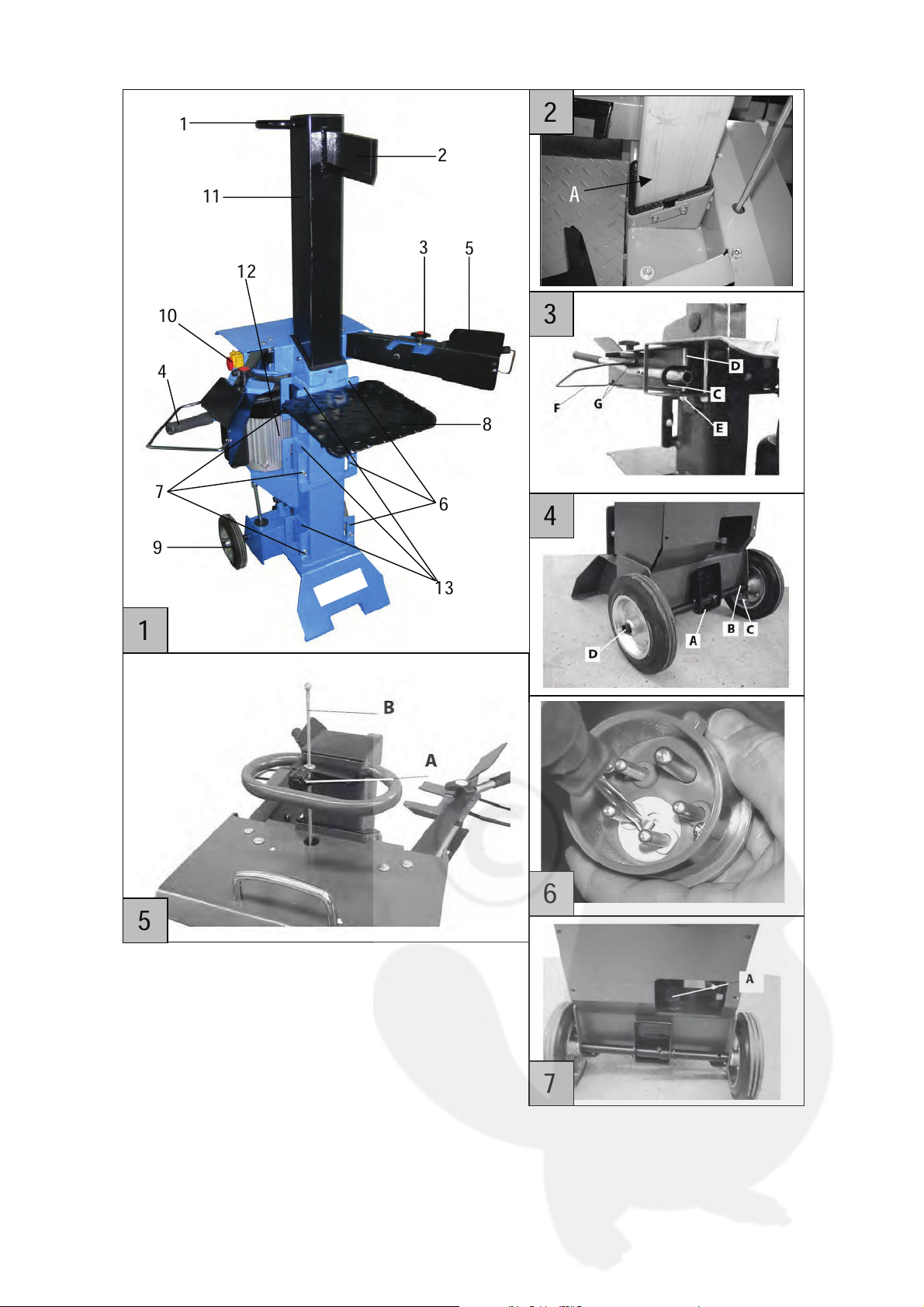

Assembly of wheels – pic. 4

Put the wheel axis with the foot lever (A) through both holes on

the oil tank. Put the M6 socket-head screw (B) through the

wheel axis and screw it with the check nut on the plate (C).

Then install the turning wheel on both sides and secure it with

a safety pin (D) on both sides. Slightly bend the safety pin to

prevent falling out.

Table assembly - pic. 1

Depending on the split wood length, the table board can be

fixed in three heights - 570 mm, 770 mm and 1,060 mm.

Table locking levers (pic. 1/7) are fixed in every assembly

position. Insert the table board to the required holders (pic.

1/12). Now secure the table board by the locking lever on

both sides.

Lift adjusting (pic. 5)

The working output can be increased for wood pieces smaller

than app. 50 cm and for more wood pieces by shortening the

backward movement of the splitting knife.

Proceed as follows:

Put a short piece of wood on the splitter table and move the

splitting knife as low as app. 2 cm above the wood. Switch the

splitter off (red button on the switch and disconnect the plug).

Now you can shorten the backward movement using the fixed

rod (pic. 5/B) by fixing the rod in the required height with the

adjusting screw (pic. 5/A).

Area of application

The appliance can only be used for wood processing. The split

material must have the following dimensions:

- Minimum diameter: 120 mm

Maximum diameter: 300 mm

- Wood splitting along fibre is only allowed.

- Risk of getting jammed at branchy wood when splitting.

- Jammed piece of wood is released by tipping on the

wood.

- Cutting the split wood out prohibited!

Split wood length adjusting

Wood of various lengths can be split depending on the splitter

type:

Electric/hydraulic connection (pic. 6 and 7)

Plugging

All splitters are fitted with undervoltage release in the switch in

accordance with provisions of branch professional

organisations “CE“, etc. The release prevents automatic

starting of the appliance in case supply is interrupted as a

result of power failure, unintentional unplugging, defective

fuse, etc. The appliance must unconditionally be switched on

again by pressing the green switching button.

Wilful holding or blocking of the switching button with no

directly earthed conductor automatically leads to switch failure.

In this case that can subsequently be identified the guarantee

expires.

The appliance meets EN 61000-3-11 requirements and is

subject to special connection conditions. That means that

use on optionally selected connection points is

inadmissible.

The appliance can lead to occasional voltage fluctuations

under unfavourable power conditions.

The appliance is only designated to be used for connection

points not exceeding the maximum allowed impedance of

Zmax = 0,233 .

As a user, you must make sure your connection point on

which you want to use the appliance meets the above-

mentioned requirements – after agreement with your

electricity supplier if necessary.

Hydraulic equipment

Tightness needs to be checked at hydraulic hoses and

couplings after app. 4 running hours and tighting must be

provided if necessary.

Only at 400 V appliances: It is necessary to be particular

about the running direction of the engine (see the arrow

on the engine) as running in wrong running direction can

damage the oil pump. In such a case, all claims arising

from the guarantee expire. If necessary, have the running

direction changed by reversal of polarity of the plug by a

professional electrician. See pic. 6! (three-phase current

models only!)

Hydraulic oil/tank

Common hydraulic oil (e.g. HLP 46 or oil of different producer

of identical viscosity) can be filled in all splitters. Oil change is

not necessary.

Vent the tank before each operation by screwing the filling

screw out and in (pic. 7/A).

Operation

Attention: Make sure wood is cut at right angle, if

possible, and seated closely on the splitting table. Cross-

cut or extremely branchy wood can slide or bend the

service arms.

Always put wood on surfaces (tables) designated for

this purpose (never on the frame). That could damage the

splitter.

1. Start the engine by pressing the green switching button.

Attention: Be particular about the running direction of

the engine at 400 V models!

2. Keep the feeder cable as short as possible at 230

V models and select as big cross section as possible.

3. When the temperature is low, let the splitter run idle

for app. 15 minutes so that oil warms up to

corresponding temperature.

4. Put the split material on the table and hold it using

clamping plates on the lever.

5. Splitting starts by pressing both levers down (as soon as

the splitting knife enters wood tip the lever slightly out

while pressing it down. This will prevent holding sheets

(arms) from bending).

6. Lift at least one lever after you have finished splitting – the

splitter pillar will automatically go up.

It is strictly prohibited to operate the wood splitter in two

persons with one holding wood and the other one

pressing on the clamping plates. Blocking one lever

(clamping plate) is prohibited, too.

Transport instructions

Transport

All wood splitters are fitted with big wheels. Grasp the handle

on the splitting pillar with one hand and handle above the

engine with the other hand and slightly tilt the splitter to you for

transport purposes. The splitter can effortlessly be moved in

this position.

To prevent hydraulic oil leakage, never transport the splitter

laid down

.

Always let the splitting knife go absolutely down for transport.

Residual risks and protective measures

Warning!!!

Taking out of operation, any change, blocking,

disassembly, changeover or assembly of all parts on

safety and protective equipment of the appliance is strictly

prohibited and can have serious consequences, i.e. life

threatening injuries if not observed.

The producer cannot be held liable for material damages

or injuries caused as a result of such negligence.

All guarantee claims towards the producer immediately

expire at each of the above-mentioned negligence.

The splitter can only be operated by one person. Remove

wood remnants that could block or negatively influence

the safety and service elements near the splitter and

workplace during operation.