HAKKI PILKE RAVEN TRANSLATION VERSION 1-2015

Table of contents

1 General information ...................................................................................................................................4

1.1 Introduction....................................................................................................................................... 4

1.2 Purpose of use ................................................................................................................................... 4

1.3 Machine models and basic information ............................................................................................ 4

1.4 Operating conditions ......................................................................................................................... 5

1.5 Safety instructions ............................................................................................................................. 5

1.6 Noise and vibration............................................................................................................................ 5

2 Setting up the machine for operation and transport .................................................................................8

2.1 Delivery inspection ............................................................................................................................ 8

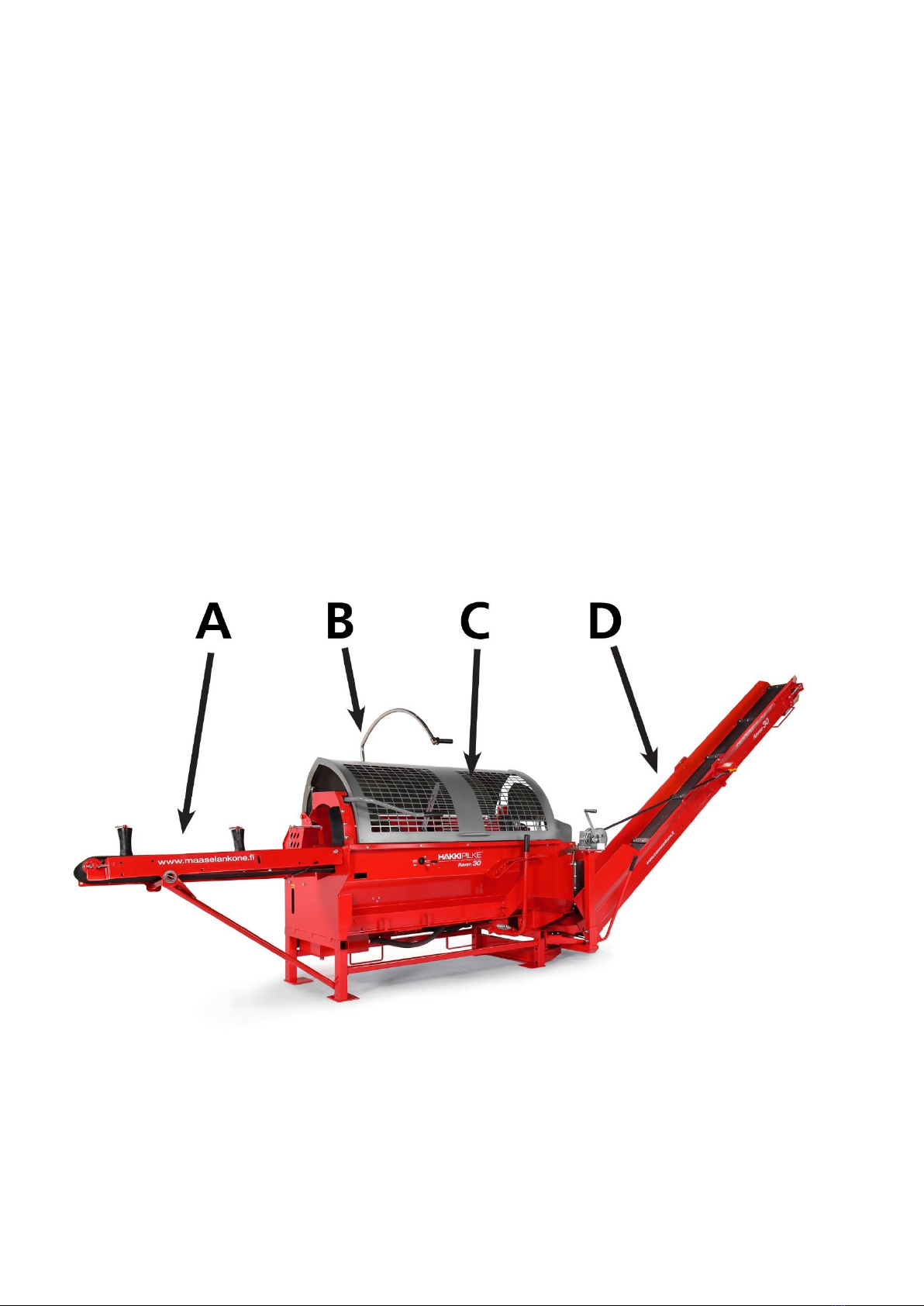

2.2 Main components of the machine .................................................................................................... 8

2.3 Arranging the machine for operation and transport......................................................................... 9

2.4 Connecting the machine to a power source.................................................................................... 13

2.5 Lifting and moving the machine ...................................................................................................... 15

2.6 Additional hydraulics connections (accessories)............................................................................. 16

2.7 In-feed conveyor belt speed control (accessory) ............................................................................ 16

3 Operating the machine............................................................................................................................ 17

3.1 machine controls and functions ...................................................................................................... 17

3.2 Performing a test run on the machine ............................................................................................ 18

3.3 Wood feeding, cutting and splitting ................................................................................................ 19

3.4 Using the output conveyor.............................................................................................................. 20

3.5 After use .......................................................................................................................................... 22

4 Maintenance and adjustment of the machine........................................................................................ 22

4.1 Disconnecting the machine from its power source......................................................................... 22

4.2 Adjusting the log length................................................................................................................... 23

4.3 Height adjustment of the splitting knife.......................................................................................... 24

4.4 Replacing the splitting knife ............................................................................................................ 25

4.5 Adjusting the tightness and alignment of the output conveyor belt .............................................. 26

4.6 Cutting blade and drive end ............................................................................................................ 27

4.7 Changing the oil............................................................................................................................... 29

4.8 Changing the oil of the multiplier gear............................................................................................ 30

4.9 Conveyor maintenance.................................................................................................................... 30

4.10 Lubrication....................................................................................................................................... 32

4.11 pressure regulating valves............................................................................................................... 36

4.12 Washing and cleaning...................................................................................................................... 37

4.13 Storage............................................................................................................................................. 37