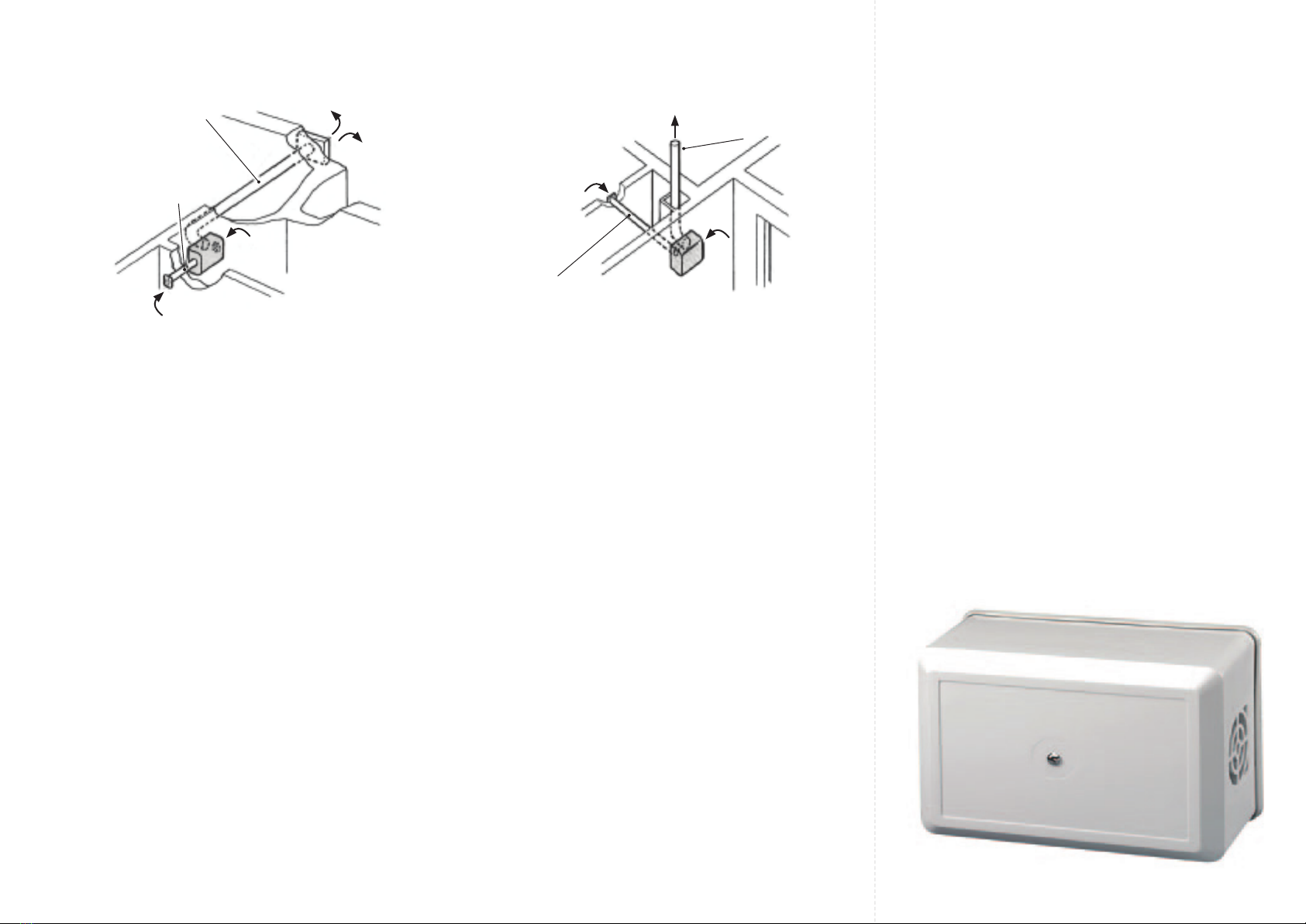

Installation

Horizontal Duct Mounting

For speed and ease of installation use Greenwood

Flexiduct.

1. Cut an opening 100mm diameter through the wall with

slight fall to exterior.

2. Remove fan cover.

3. Drill and plug 4 screw holes suitable for No.8 screws.

4. Fit adhesive foam plastic strip around exhaust spigot (not

required if exiduct hose-clip is used).

5. Fit adhesive foam plastic strip around secondary inlet

spigot if required.

6. Fit rubber sealing strip around base plate of unit.

Ensuring that is has shortest side outward. (P1 only).

7. Fit anti-back-draught shutter into exhaust spigot ensuring

hinge is to the top. (P1 only).

8. Fit base plate to wall using No.8 screws.

Note: PD only to t, motor chassis may be unscrewed

and unplugged from the base plate before xing base

plate to the wall.

9. Fit timer if required.

(See separate installation instructions).

10. Wire fan as required. (See wiring diagram).

11. If cable knock outs in Terminal Block Cover are removed,

ensure that the edges of the knock outs are dressed so

that the external cable insulation is not damaged by any

sharp edges.

12. Replace cover, ensuring printed circuit tongue locates in

the electrical connector and is fully home.

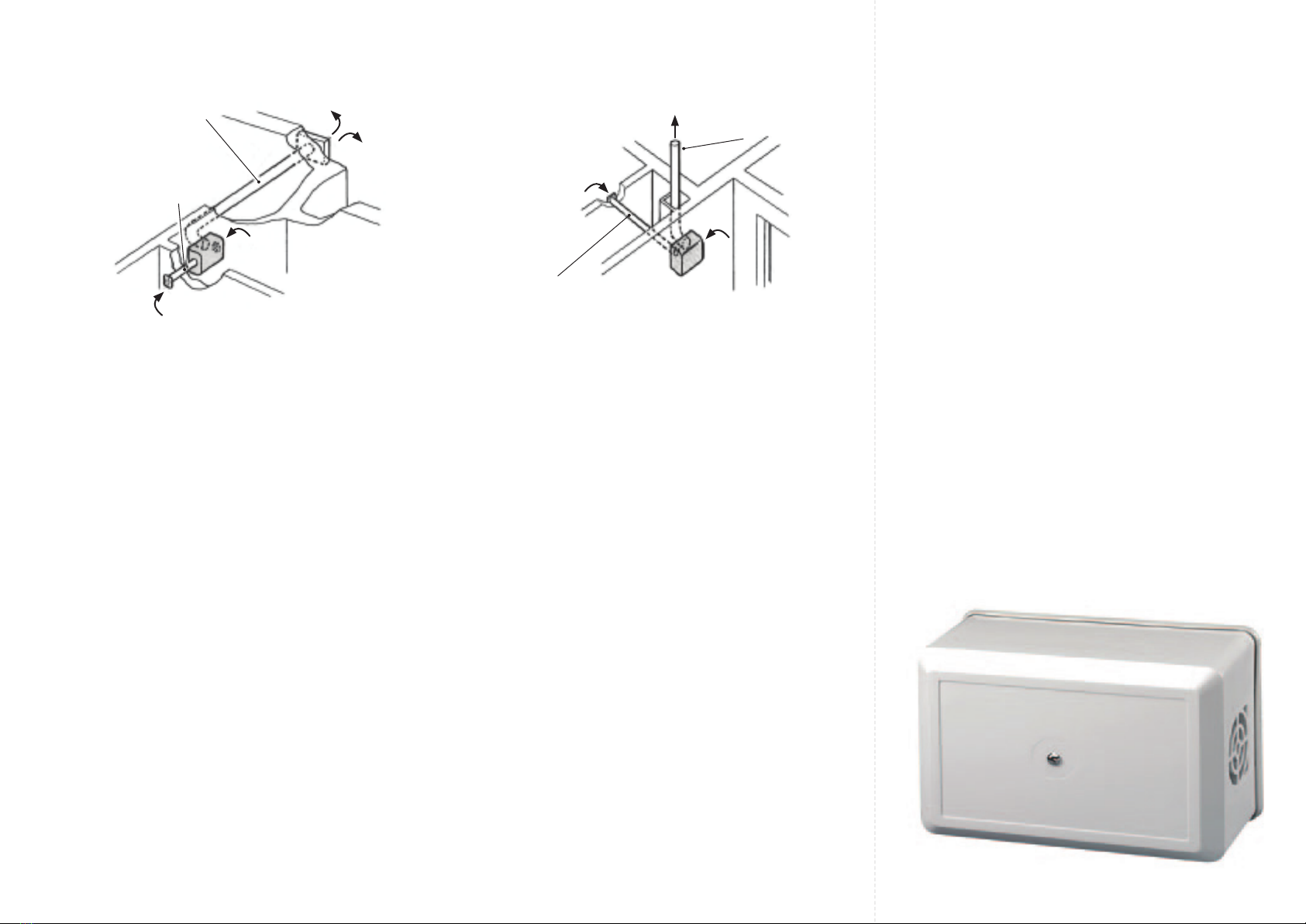

Installation

Vertical Duct Mounting

For speed and ease of installation use Greenwood

Flexiduct.

1. Cut an opening 100mm diameter through the wall with a

set in duct.

2. Remove fan cover.

3. Drill and plug 4 screw xing holes.

4. Fit adhesive foam plastic strip around exhaust spigot (not

required if exiduct hose-clip is used).

5. Fit adhesive foam plastic strip around secondary inlet

spigot if required.

6. Fit rubber sealing strip around base plate of unit. Ensuring

that is has shortest side outward. (P1 only).

7. Fit anti-back-draught shutter into exhaust spigot ensuring

hinge is to the top. (P1 only).

8. Fit base plate to wall using No.8 screws.

Note: PD only to t, motor chassis may be unscrewed and

unplugged from the base plate before xing base plate to

the wall.

9. Fit timer if required.

(See separate installation instructions).

10. Wire fan as required. (See wiring diagram).

11. If cable knock outs in Terminal Block Cover are removed,

ensure that the edges of the knock outs are dressed so

that the external cable insulation is not damaged by any

sharp edges.

12. Replace cover, ensuring printed circuit tongue locates in

the electrical connector and is fully home.

Wiring Notes

1. All wiring must be in accordance with prevailing

national standards (eg. BS7671 IEE UK Wiring

Regulations) and carried out by a qualied

electrician.

2. Switch off mains supply before commencing any

installation, electrical, cleaning, or servicing work.

3. A double pole isolating switch with a minimum

contact gap of 3mm should be used in series with

each fan.

4. For single units use a 3 amp fuse. When supplied

from a 6 amp lighting circuit no local fuse is required.

5. To wire the unit:

a. Remove the fan cover.

b. Remove screws securing connector block.

c. Remove earth test wire and discard.

d. Make all connections on rear of connector block

Note: No mains connections are to be made to the

front of the electrical connector at this will by-pass

the electrical isolator.

e. Replace screws securing connector block.

f. Replace cover, ensuring printed circuit tongue

engages in the electrical connector and is

fully home.

100mm Primary Duct

60mm Secondary Duct

100mm Primary Duct

60mm Secondary Duct