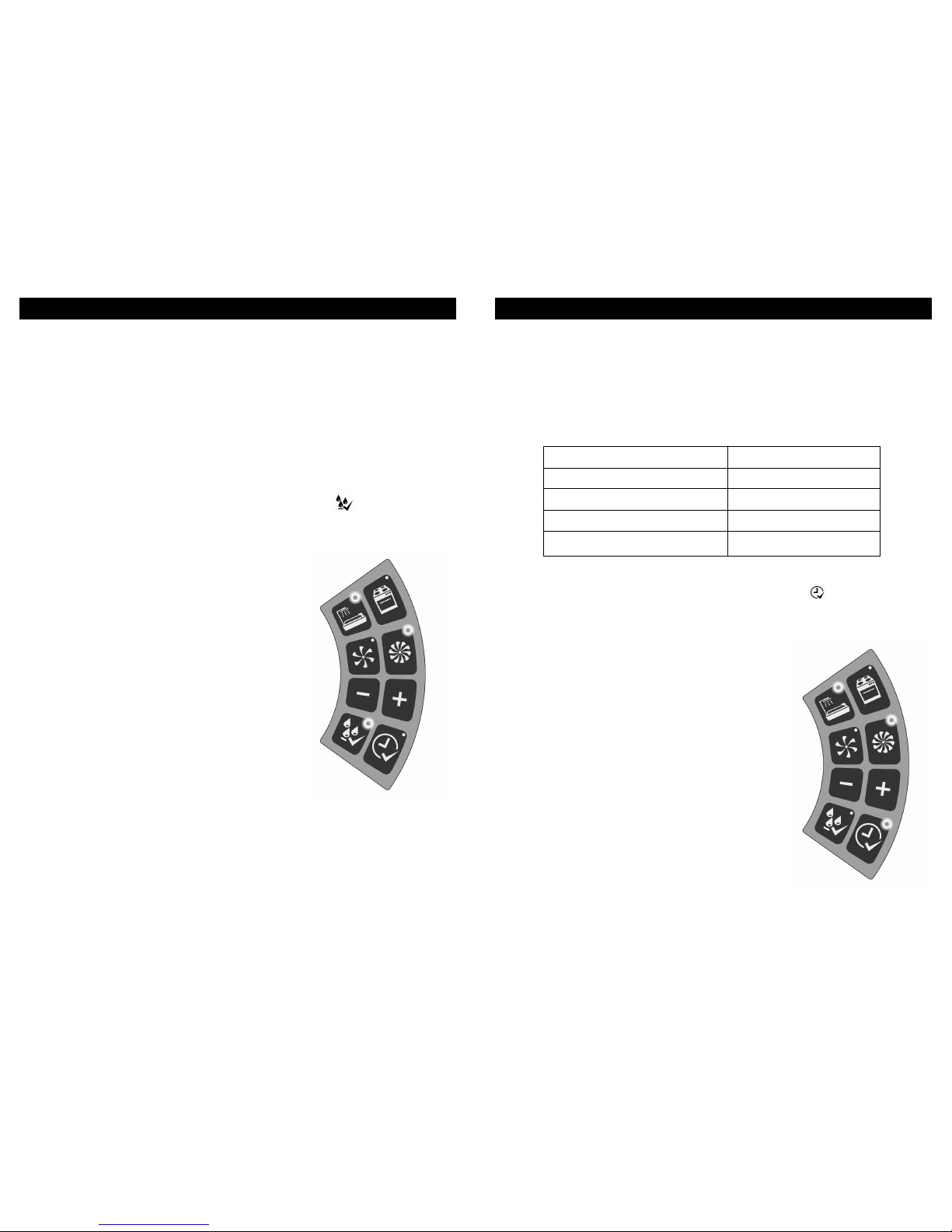

The specific operation of your fan may vary depending on the way it has

been installed.

The options are –

Trickle Speed: Operating on a continual basis.

Boost Speed: Activated manually using our GS2 switch or via the

room light switch.

GS2 switch markings - Trickle (I) & Boost (II)

Operation

Note: Other manufacturers switches may show different markings.

To maintain a healthy indoor environment the Unity CV2GIP / CV2SVGIP

includes SMART technology for Over-run Timer (Greenwood

TimerSMARTTM) and Humidity (Greenwood HumidiSMARTTM).

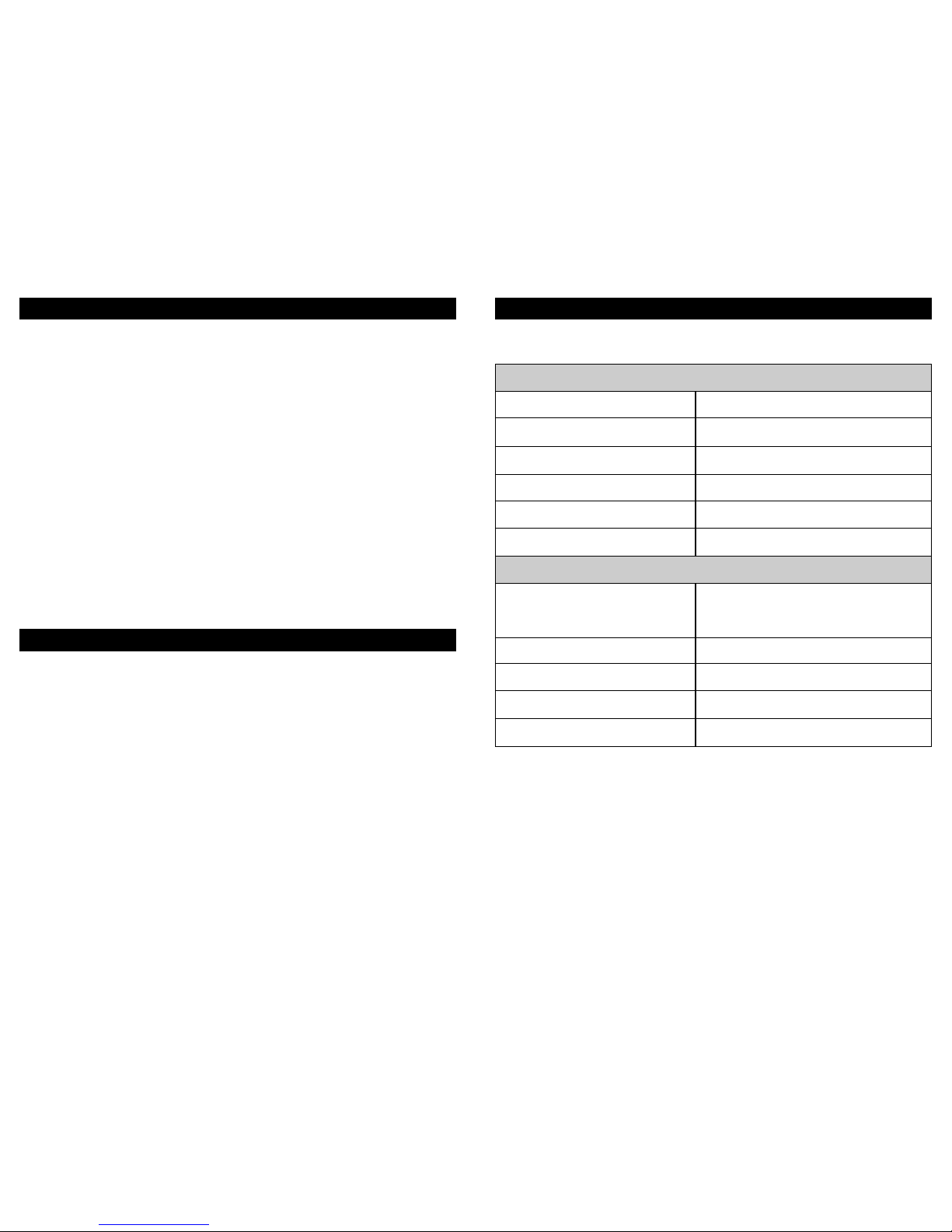

Greenwood TimerSMARTTM monitors the length of time that there is an

occupancy presence within a wet room (via the ‘switch-live’) and provides

a fixed over-run time period to best match the length of time that the

‘switch live’ is active (as shown below):

Note: The first 5 minutes will not activate an over-run.

This removes nuisance running noise and unnecessary energy wastage

typically associated with traditional timers.

4 5

2.0 General Overview

2.1.1

2.1.2

2.1.3

Greenwood HumidiSMARTTMmonitors the ambient humidity within the

wet room environment and looks for short peaks of humidity made by

either showering or bathing. This smart technology ensures that your

Unity CV2GIP / CV2SVGIP is not on boost for prolonged periods of time

removing nuisance running noise and unnecessary energy wastage

typically associated with increases to background humidity which

naturally occurs with the changing seasons.

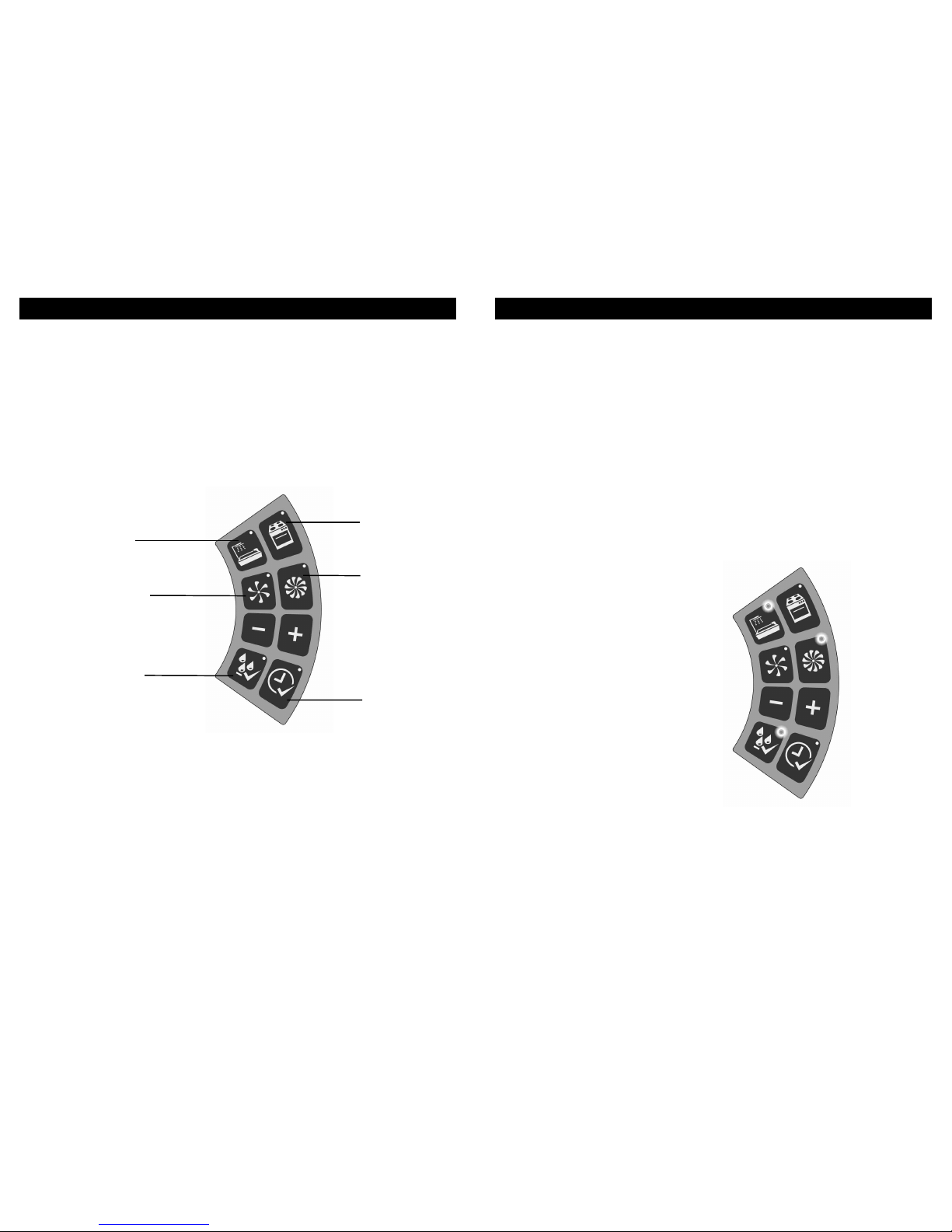

To maintain good indoor air quality within the dwelling it is important

that the fan remains in operation at all times unless switched off for

maintenance. (See section 4.0 Servicing / Maintenance).

Depending on when your home was built background window trickle

ventilators may be provided in dry habitable rooms. Trickle vents should

not be installed in the same rooms as the fan, as overall ventilation

effectiveness can be reduced.

Warning: This appliance can be used by children aged from 8

years and above and persons with reduced physical sensory or

mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance.

Where an open-flued oil or gas-fuelled appliance is installed

precaution must be taken to avoid a back-flow of gases into

the room.

The CV2SVGIP fan must only be installed by using the supplied

Safety Extra Low Voltage (SELV) controller corresponding to the

markings on the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

Always isolate fan from mains supply before cleaning. Do not use

solvents to clean this fan.

2.1.4

2.1.5

2.1.6

2.1.7

2.1.8

2.1.9

2.1.10

2.1.11

II

I

Time ‘Switch Live’ is Active

0– 5 minutes

5–10 minutes

10 – 15 minutes

15+ minutes

Over-run Boost Period

No over-run

5 minutes

10 minutes

15 minutes