Table of contents

2 / 28 B-H88.0.14.DB2-1.0

Table of contents

1 About this documentation ................................................................................................................. 4

1.1 Foreword............................................................................................................................................... 4

1.2 Purpose of the document...................................................................................................................... 4

1.3 Legal notices......................................................................................................................................... 4

1.4 Correctness of content.......................................................................................................................... 4

1.5 Layout of this document........................................................................................................................ 4

1.6 Further information ............................................................................................................................... 5

2 Safety ................................................................................................................................................... 6

2.1 Explanation of safety symbols .............................................................................................................. 6

2.2 Safety instructions ................................................................................................................................ 6

2.3 Foreseeable misuse ............................................................................................................................. 6

2.4 Intended use ......................................................................................................................................... 6

2.5 Qualified personnel............................................................................................................................... 7

3 Description .......................................................................................................................................... 8

3.1 Scope of delivery .................................................................................................................................. 8

3.2 Functional description........................................................................................................................... 8

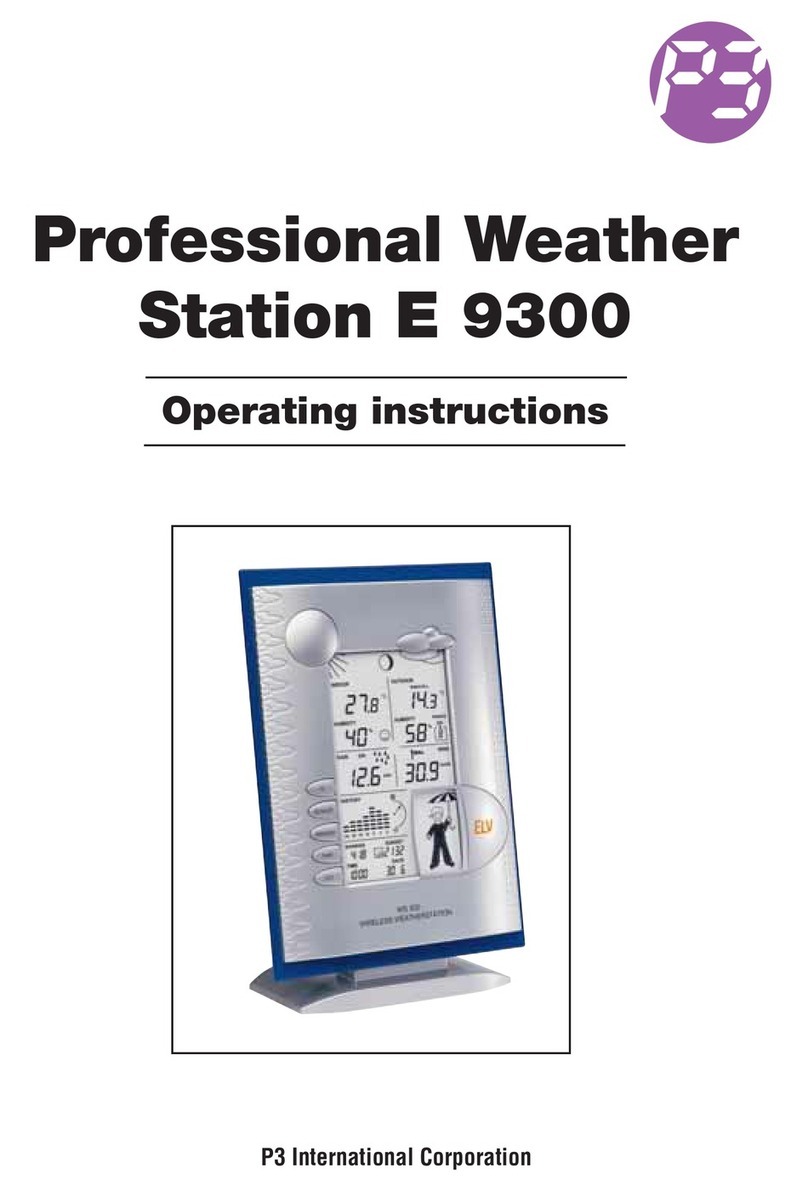

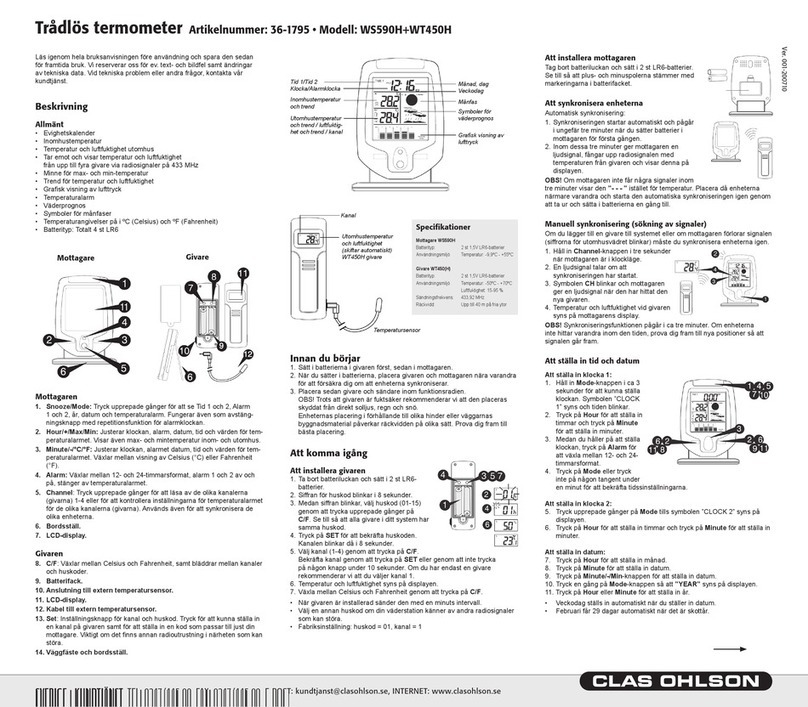

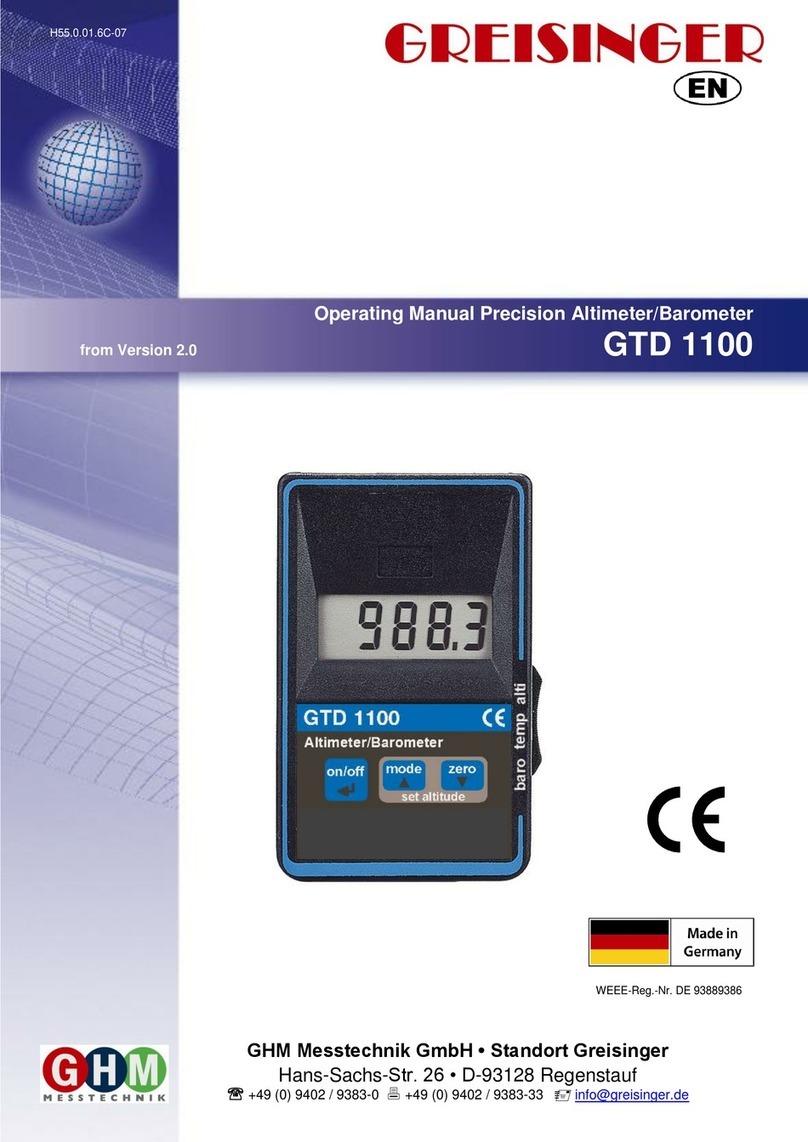

4 The product at a glance ..................................................................................................................... 9

4.1 The G 1114........................................................................................................................................... 9

4.2 Display elements .................................................................................................................................. 9

4.3 Operating elements .............................................................................................................................. 9

4.4 Connections........................................................................................................................................ 10

5 Operation........................................................................................................................................... 11

5.1 Commissioning ................................................................................................................................... 11

5.1.1 Explanation ......................................................................................................................................... 11

5.2 Configuration ...................................................................................................................................... 11

5.2.1 Explanation ......................................................................................................................................... 11

5.2.2 Opening the configuration menu......................................................................................................... 11

5.2.3 Configuring parameters of the configuration menu............................................................................. 12

5.2.4 Open the adjustment menu ................................................................................................................ 13

5.2.5 Parameters of the adjustment menu................................................................................................... 14

6 Measurement Basics ........................................................................................................................ 16

6.1 Vacuum measurements...................................................................................................................... 16

6.2 Special functions................................................................................................................................. 16

6.2.1 NVLL Tare function ............................................................................................................................... 16

6.2.2 AVR 0:02 / AVR 0:05 / AVR 0: 10 ............................................................................................................. 16

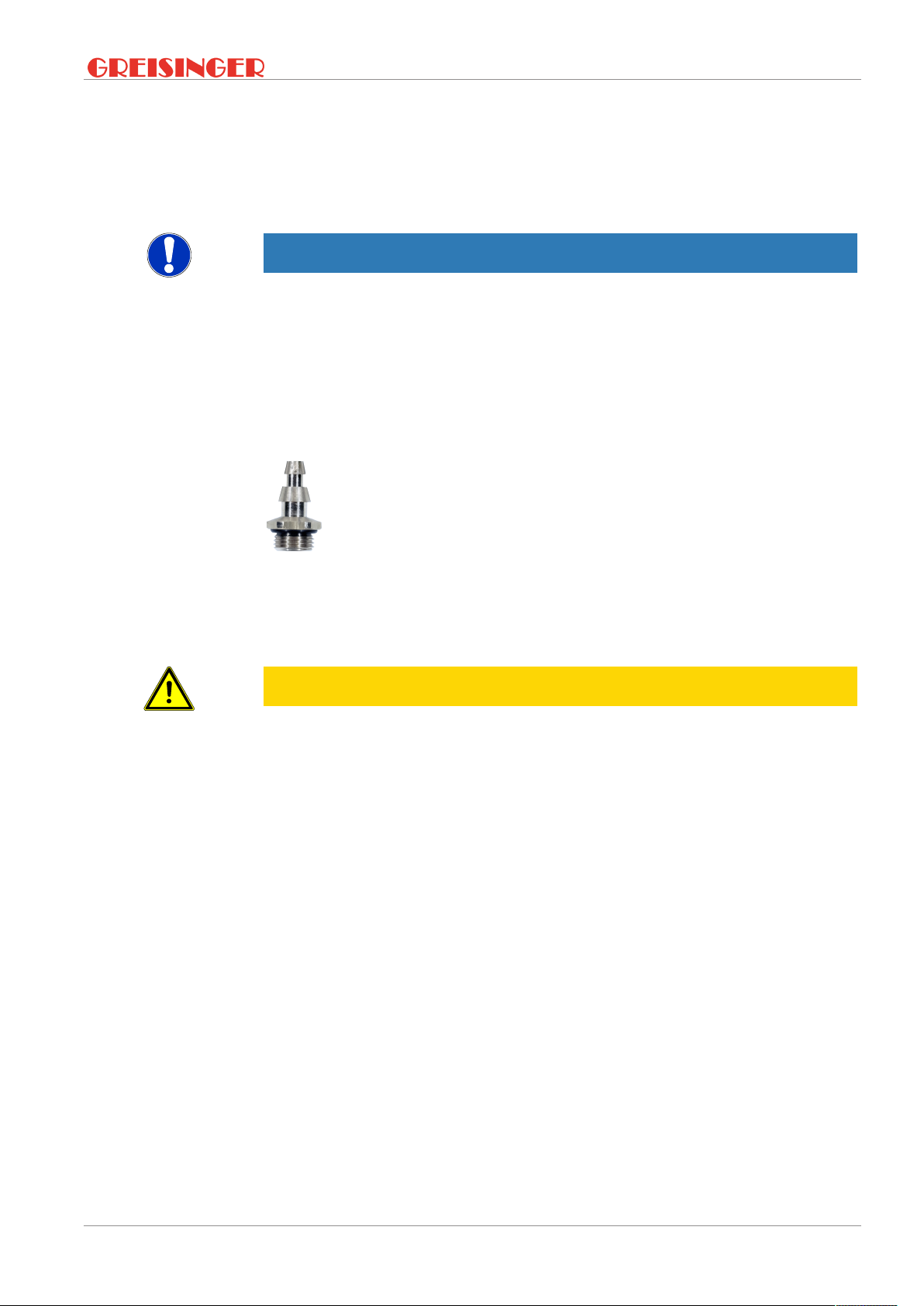

6.3 Pressure connections ......................................................................................................................... 17

6.4 UT operation ....................................................................................................................................... 17

6.5 QC6 operation .................................................................................................................................... 18

6.6 ST6 operation ..................................................................................................................................... 18

6.7 MCM operation ................................................................................................................................... 18

6.8 Replacement of pressure hoses ......................................................................................................... 19

6.9 Protection of sensors with use of filter membranes ............................................................................ 19

7 Operation and maintenance ............................................................................................................ 20

7.1 Operating and maintenance notices ................................................................................................... 20