www.gritomatic.com

Note: When you read about knife sharpening, you may come across the term “full

sharpening angle.” This means the sum of the two angles used to sharpen both sides of a

blade (e.g. 15 one side + 15 the other side = 30 full sharpening angle). As a result, when

using the Hapstone, you need to divide the value of the full angle by 2 to get the value of

the angle you need to set on the Hapstone.

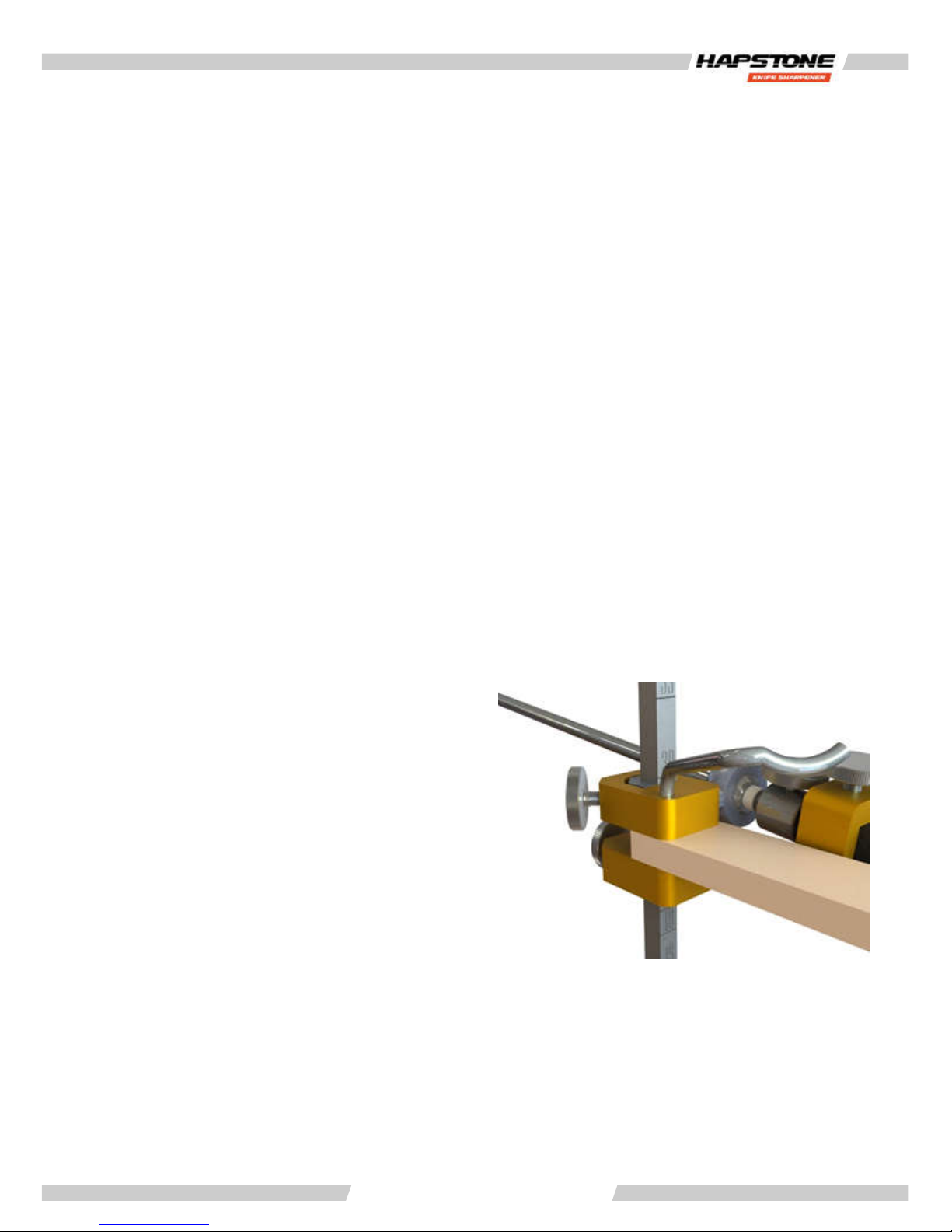

You'll see angle marks for knife sharpening (at 15, 18, 20, 25, 30, 35 and 40 degrees) on

the pivot rod of the Hapstone knife sharpener. On the lower part of the pivot rod, there is

a mark with the smallest angle value, on the upper part, the largest.

Note. The actual sharpening angle also depends on the thickness of the knife spine. The

thicker the knife spine is, the less the actual angle is. For example, if the knife thickness is

3 mm, the knife sharpening half angle is reduced by about 2 degrees. Keep this in mind

when sharpening.

4 2 . .Using the thickness compensator

Because the sharpening stones vary in size and thickness, the sharpening angle varies as

well. The thicker the sharpening stone is, the smaller the sharpening angle you get. The

thickness compensator helps to keep sharpening angle the same.

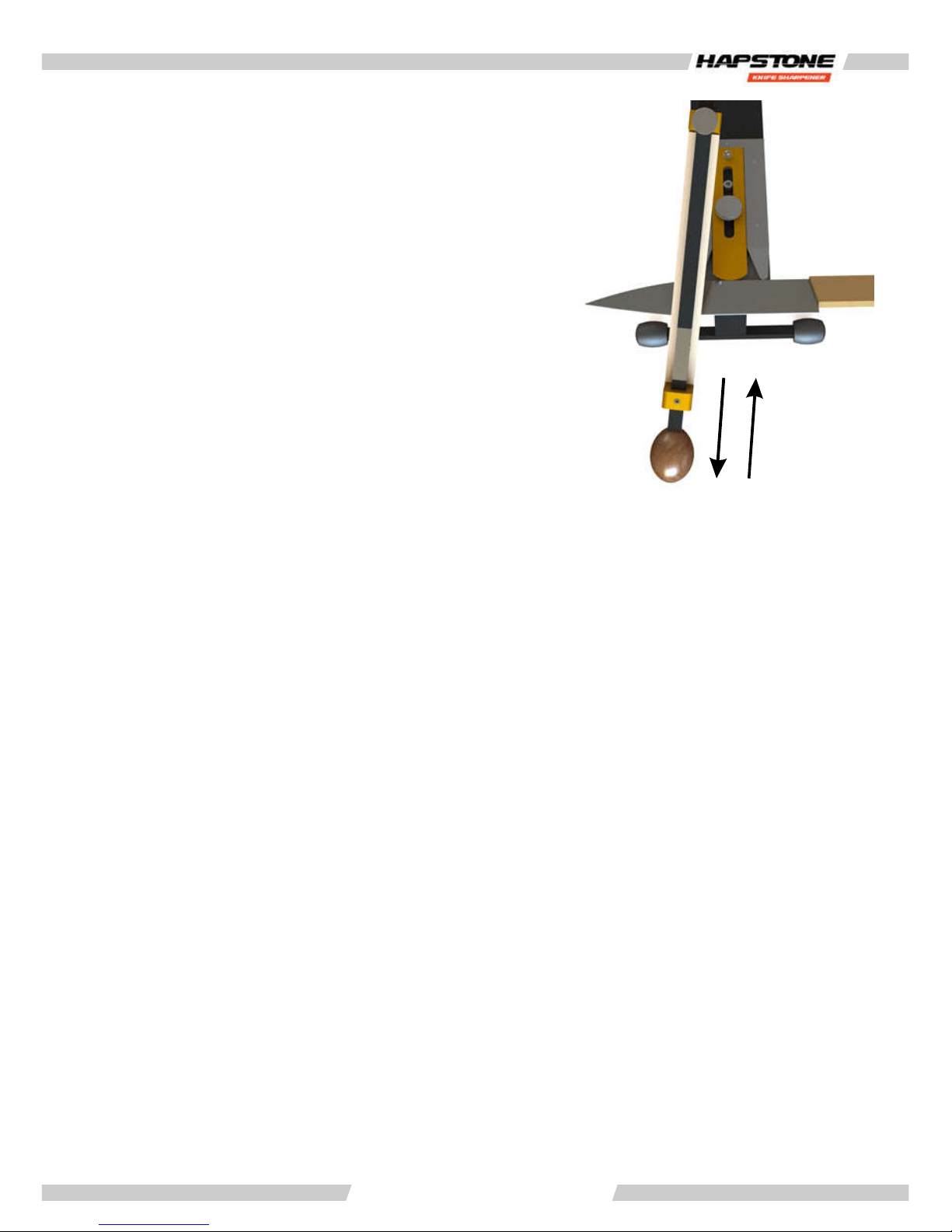

After choosing a sharpening angle, lift the

thickness compensator on the pivot rod up

to the necessary angle indicator mark. The

upper side of the thickness compensator

should be on the level of the chosen angle

indicator mark. Next, fasten the compensator

on the pivot rod with the thumb screw. When

setting the angle of sharpening, the

thickness of the sharpening stone should be

taken into consideration. To do this, before

setting the sharpening stone, put it with its

horizontal surface down onto the surface of

the thickness compensator. Lower the pivot

to securely fasten the sharpening stone

between the thickness compensator and

pivot.