Introduction

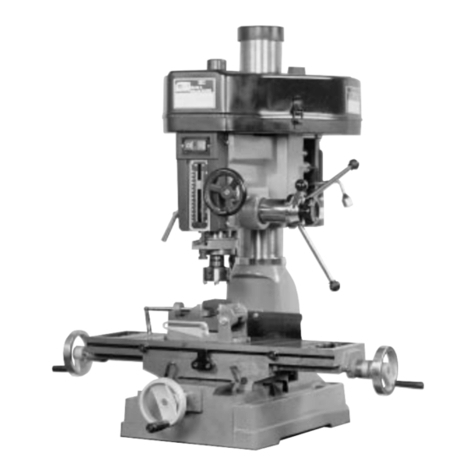

The Model H7819 High Speed Steel Tap and Drill

Set comes supplied with six of the most commonly

used coarse thread sizes with the corresponding

tap drill. Each size set has taps with taper, plug,

and bottoming grinds, allowing you to choose the

right tap for any job. Tap handle not included.

Inventory

A. 27⁄64" Tap Drill .............................................. 1

B. 1⁄2"-13 Plug Tap .......................................... 1

C. 1⁄2"-13 Bottoming Tap ................................. 1

D. 1⁄2"-13 Taper Tap ........................................ 1

E. 5⁄16" Tap Drill ............................................... 1

F. 3⁄8"-16 Plug Tap .......................................... 1

G. 3⁄8"-16 Bottoming Tap ................................. 1

H. 3⁄8"-16 Taper Tap ........................................ 1

I. F Tap Drill ................................................... 1

J. 5⁄16"-18 Plug Tap ......................................... 1

K. 5⁄16"-18 Bottoming Tap ................................ 1

L. 5⁄16"-18 Taper Tap ....................................... 1

M. #7 Tap Drill ................................................. 1

N. 1⁄4"-20 Plug Tap .......................................... 1

O. 1⁄4"-20 Bottoming Tap ................................. 1

P. 1⁄4"-20 Taper Tap ........................................ 1

Q. #25 Tap Drill ............................................... 1

R. #10-24 Plug Tap ......................................... 1

S. #10-24 Bottoming Tap ................................ 1

T. #10-24 Taper Tap ...................................... 1

U. #29 Tap Drill ............................................... 1

V. #8-32 Plug Tap ........................................... 1

W. #8-32 Bottoming Tap .................................. 1

X. #8-32 Taper Tap ........................................ 1

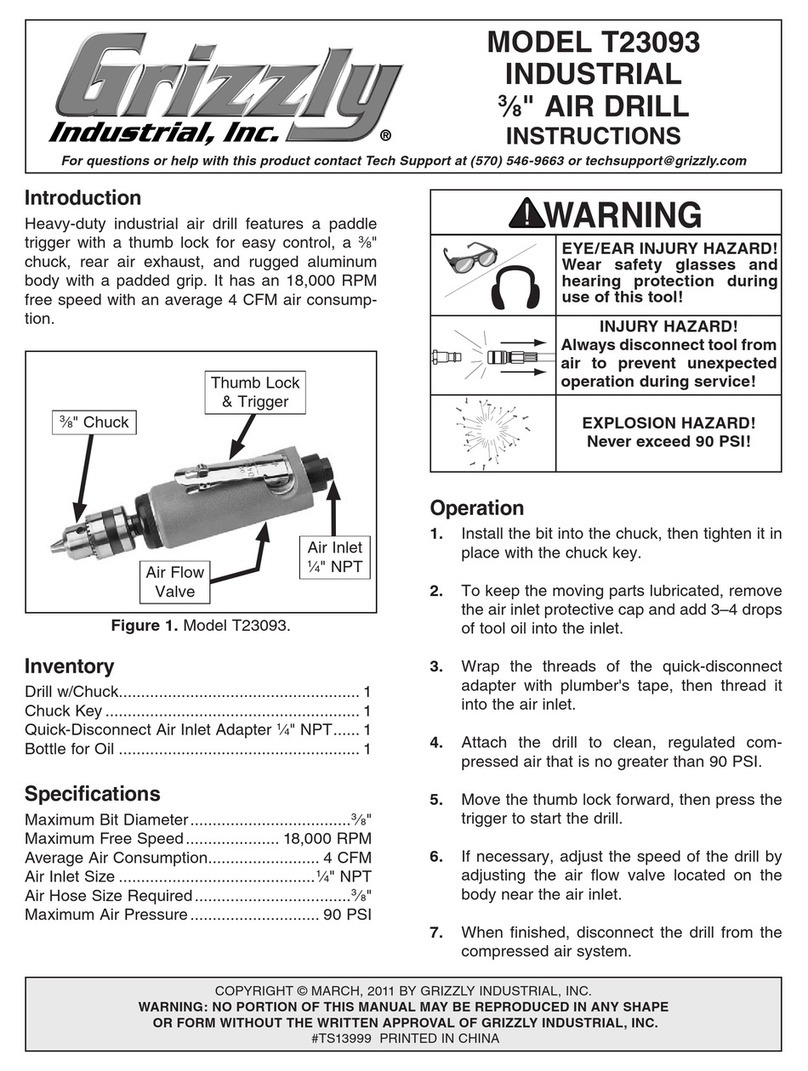

MODEL H7819

24-PC H.S.S. DRILL &

TAP SET

INSTRUCTION SHEET

Figure 1. Model H7819.

COPYRIGHT © AUGUST, 2006 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#PC8462 PRINTED IN CHINA

Always wear safety

glasses when tapping!

Identification

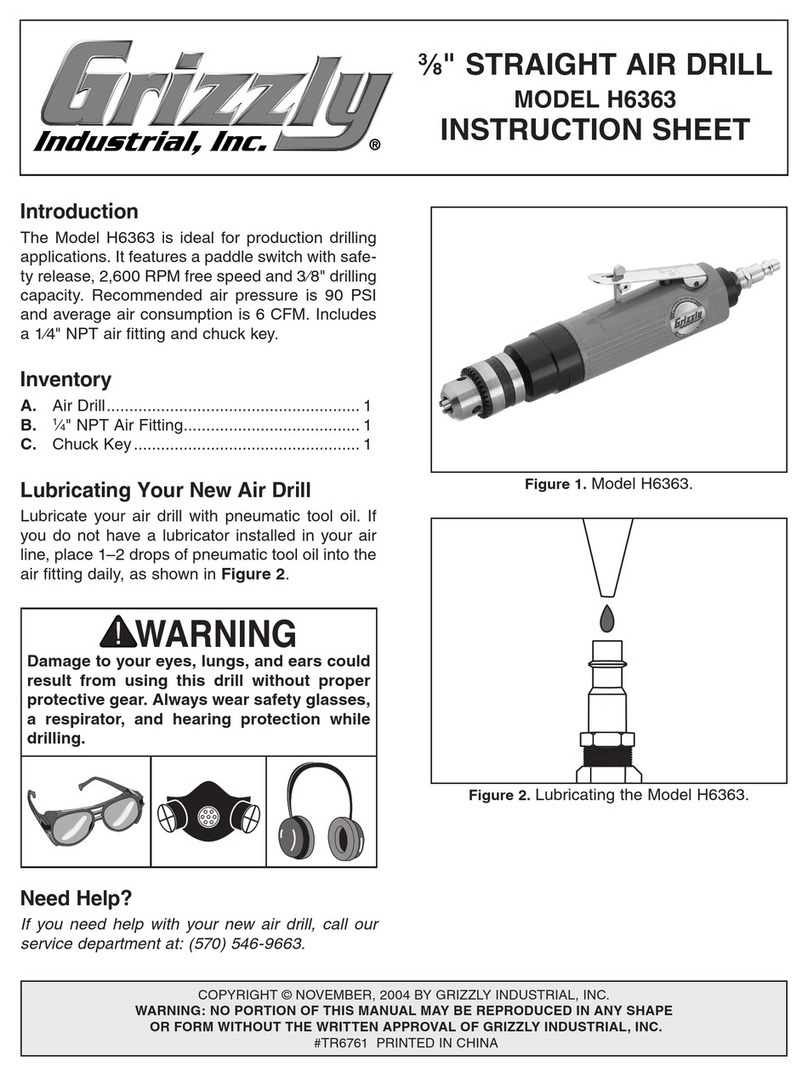

Tapered Taps: Tapered taps have 7-10 threads

at the bottom that are tapered. The lengthened

taper on these taps makes it easier to keep the

tap straight as the cutting begins.

Plug Taps: Plug taps have 3-4 threads at the bot-

tom that are tapered. Plug taps follow the tapered

tap. Plug taps are designed for tapping open or

"through holes." They can also be used for start-

ing threads on easily cut materials like aluminium,

brass and cast iron.

Bottoming Taps: Bottoming taps have 1-2 threads

at the bottom that are tapered. Bottoming taps are

generally used for cutting threads as close as

possible to the bottom of a hole or "blind holes."

The bottoming tap is usually used after threads

have been started with the taper tap or the plug

tap (see Figure 2).

Tap Drill: The tap drill is a standard jobber type

drill used for drilling the pilot hole.