-6- Model G0704 (Mfg. Since 0 8 /11)

The information contained herein is deemed accurate as of 3/3/2014 and represents our most recent product specifications.

Due to our ongoing improvement efforts, this information may not accurately describe items previously purchased. PAGE 2 OF 3Model G0704

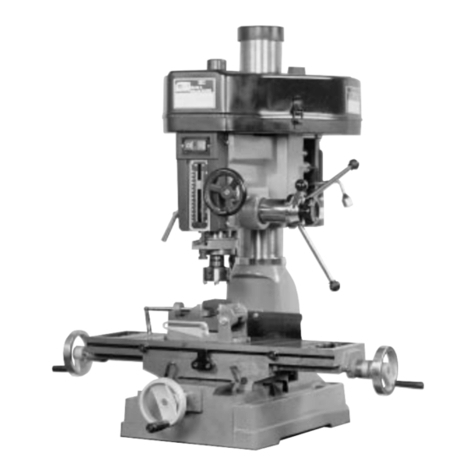

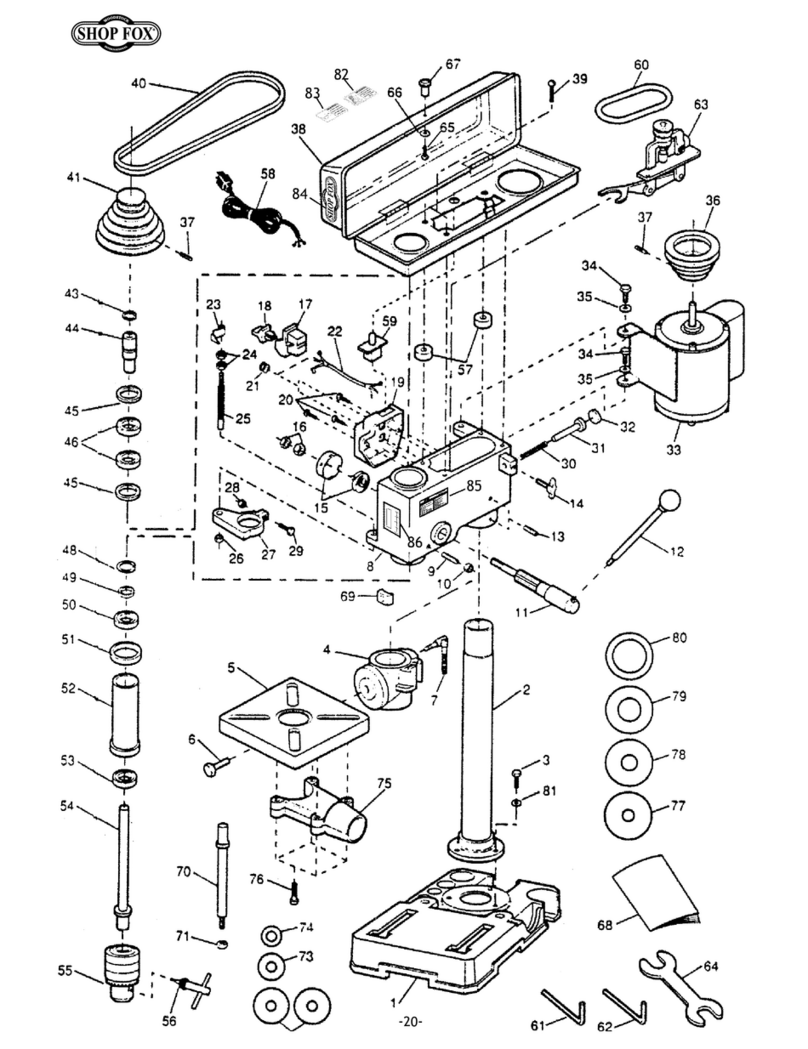

Main Specifications:

Operation Info

Spindle Travel.............................................................................................................................................. 2 in.

Max Distance Spindle to Column.......................................................................................................... 7-1/2 in.

Max Distance Spindle to Table.................................................................................................................. 13 in.

Longitudinal Table Travel (X-Axis)...................................................................................................... 18-7/8 in.

Cross Table Travel (Y-Axis).................................................................................................................. 6-7/8 in.

Vertical Head Travel (Z-Axis)..................................................................................................................... 11 in.

Head Tilt (Left/Right).............................................................................................................................. 90 deg.

Drilling Capacity for Cast Iron................................................................................................................... 3/4 in.

Drilling Capacity for Steel......................................................................................................................... 5/8 in.

End Milling Capacity................................................................................................................................. 3/4 in.

Face Milling Capacity............................................................................................................................ 2-1/2 in.

Table Info

Table Length........................................................................................................................................ 26-5/8 in.

Table Width......................................................................................................................................... 7-1/16 in.

Table Thickness.................................................................................................................................... 1-3/4 in.

Number of T-Slots............................................................................................................................................ 3

T-Slot Size................................................................................................................................................ 1/2 in.

T-Slots Centers...................................................................................................................................... 2-1/2 in.

Spindle Info

Spindle Taper............................................................................................................................................... R-8

Number of Vertical Spindle Speeds...................................................................................................... Variable

Range of Vertical Spindle Speeds............................................................................................. 50 – 2250 RPM

Quill Diameter......................................................................................................................................... 2.36 in.

Drawbar Thread Size............................................................................................................................. 7/16-20

Drawbar Length................................................................................................................................. 9-11/16 in.

Spindle Bearings......................................................................................................... Tapered Roller Bearings

Construction

Spindle Housing/Quill........................................................................................................................... Cast Iron

Table....................................................................................................................... Precision-Ground Cast Iron

Head.................................................................................................................................................... Cast Iron

Column/Base....................................................................................................................................... Cast Iron

Base..................................................................................................................................................... Cast Iron

Stand.......................................................................................................................................................... Steel

Paint....................................................................................................................................................... Enamel

Other Specifications:

Country Of Origin ............................................................................................................................................... China

Warranty ........................................................................................................................................................... 1 Year

Approximate Assembly & Setup Time .............................................................................................................. 1 Hour

Serial Number Location ...................................................................................................... ID Label on Head Casting

Sound Rating ..................................................................................................................................................... 80 dB

ISO 9001 Factory .................................................................................................................................................. Yes

CSA Certified .......................................................................................................................................................... No

Features:

Digital spindle scale reads metric, inches, zero, set, on/off

Forward/reverse switch

Chip guard

Digital display for spindle speed

Dovetail column

Front mounted fine feed knob

Coolant trough