-4- © 2002 Grizzly Industrial, Inc.

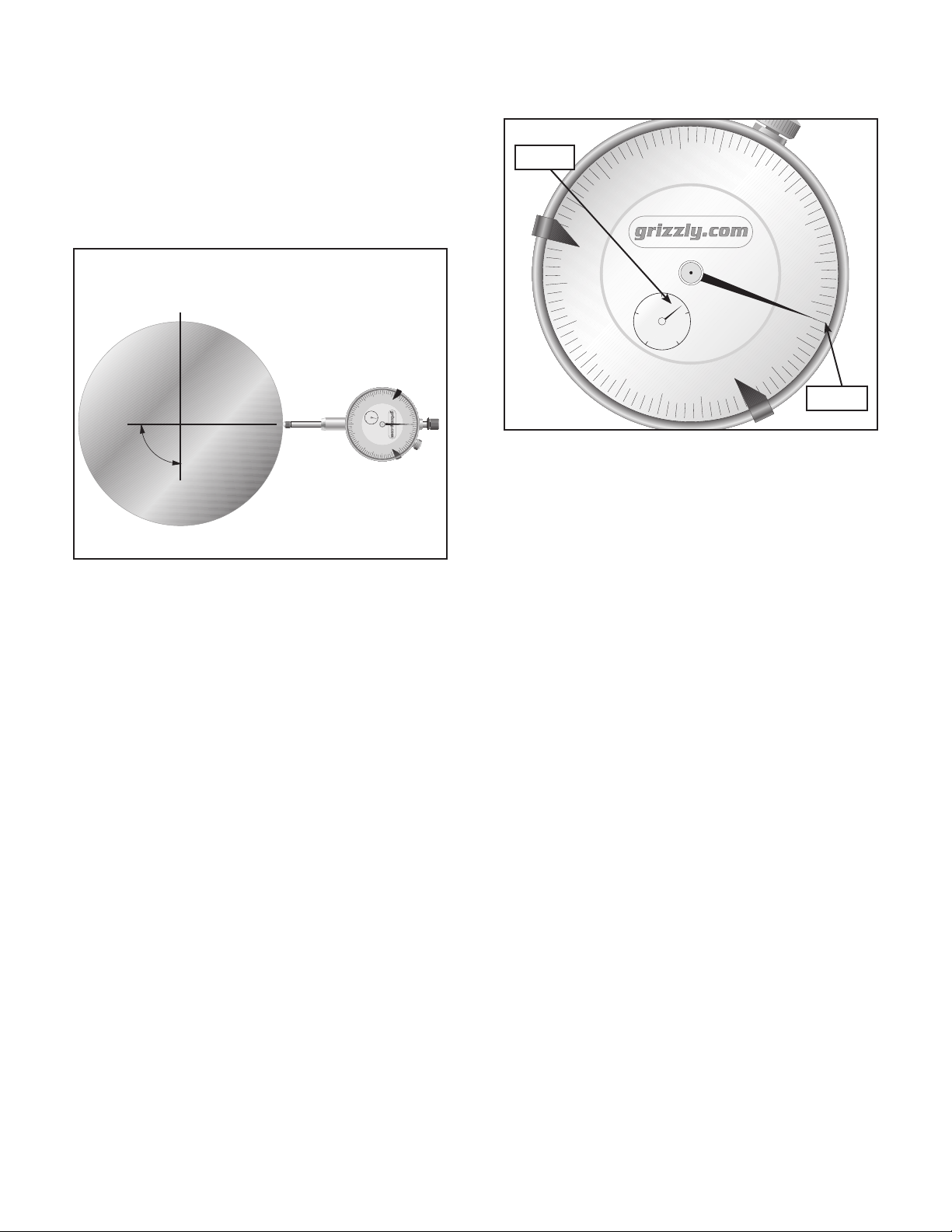

Dial Lock

Loosening the dial lock allows the dial face to

be rotated. This can be helpful when an absolute

measurement is desired and changing the adjust-

ments to the column, boom and fine adjustment

knob are difficult or impractical. In Figure 9 the

dial face has been rotated.

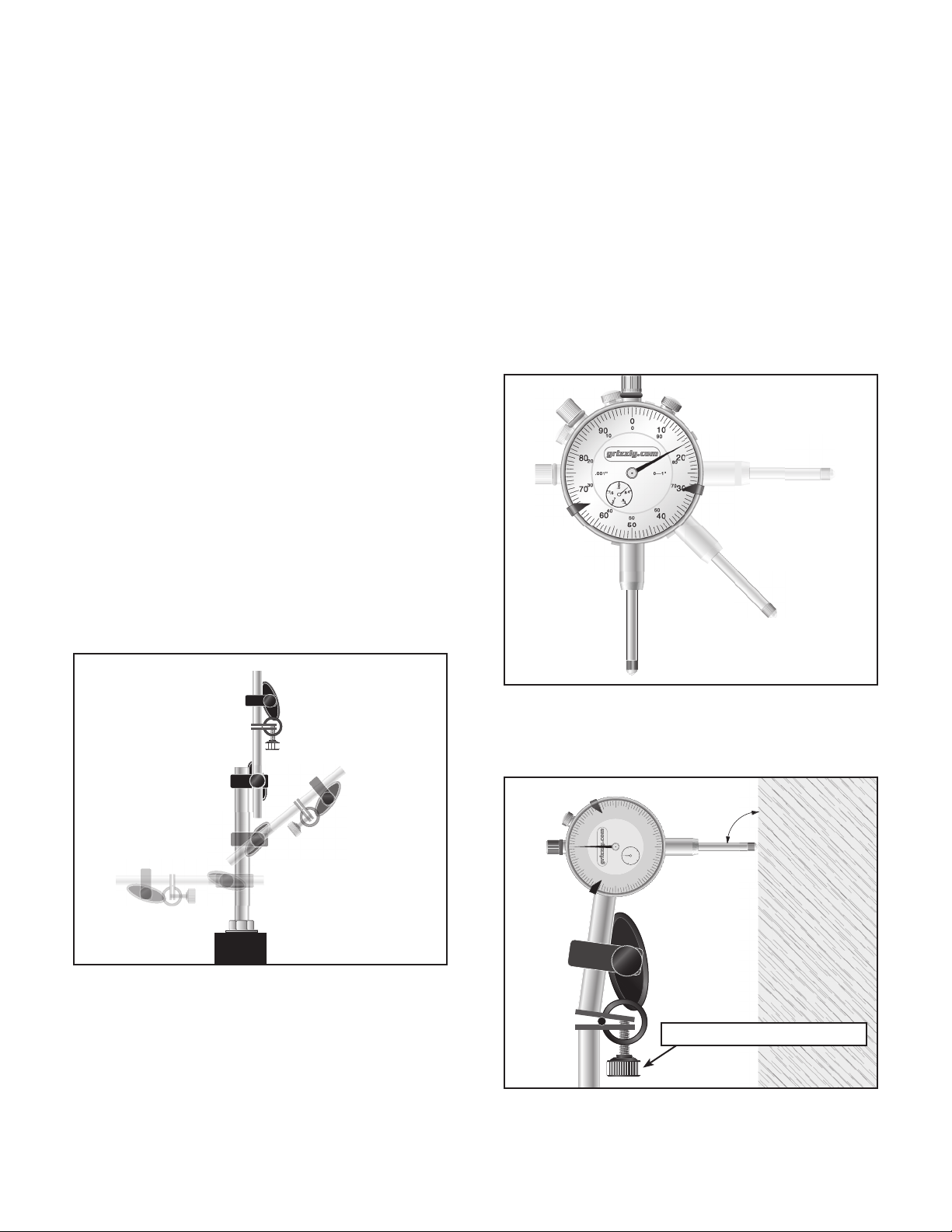

Setting the Contact Point

One of the most important setup issues with a

dial indicator is to make sure the contact point

is perpendicular to its expected motion or to

the motion of the object to be tested. Failure to

ensure proper setup will result in an error in mea-

surement. Please refer to Figure 7 and 8.

Another important note about setup is that the

contact point must be resting against the part

before any change can be indicated. It is there-

fore necessary to adjust the unit so the needle

has moved to ensure a proper measurement.

Use the fine-tune adjustment knob illustrated in

Figure 7.

Reading the Dial

Adjustable Markers

The dial indicator is calibrated to read 0.001" and

has a range of 1". When the contact point is not

touching anything, the pointers for each dial will

read “under” the zero inch mark.

It is important to understand that the pointers

rotate in opposite directions as the contact point

is depressed. The pointer for the large dial rotates

clockwise and the pointer for the smaller dial

rotates counterclockwise when the contact point

is depressed. You must keep track of the number

of revolutions for the smaller dial! The first revolu-

tion is indicated by the numbers on the outer ring

of the numbers and the second revolution is indi-

cated by the innermost numbers. The example in

Figure 9 indicates 0.417".

As with the decade counter, the main dial has

a second set of numbers. These can be used

to keep track of the actual motion of the contact

point when it is released.

The dial indicator can also be set up to be used

as a range tester. There are 2 adjustable mark-

ers that can be positioned on the dial face. A

range can then be checked. In the example in

Figure 9, the adjustable markers have been set

to measure between 0.030" and 0.065". Again, if

a larger range than 0.100" is needed, the revolu-

tions of the pointer on the smaller dial will have

to be counted.

10

20

30

40

50

60

70

80

90

0

0

.5

.4

.9

.3

.8

.2

.7

.1

.6

.001'' 0—1''

20

10 90

80

70

60

50

40

30

0

Figure 9. The dial reads 0.417".

10

20

30

40

50

60

70

80

90

0

0

.5

.4

.9

.3

.8

.2

.7

.1

.6

.001'' 0—1''

20

10 90

80

70

60

50

40

30

0

C

L

90˚

Figure 8. The indicator is positioned perpendic-

ular to the axis of a round bar. When the bar is

turned, the runout or lateral motion is indicated

by motion of the needle.

0.400"

0.017"

462402622