915.710057-V3.0

U 189-010 en

6 Fault Correction

The numbers in brackets occurring in the following refer to the

items of the enclosed sectional drawings 15.189-200 and

12.4188-300.

FAULT

No changing over

The change - over device

switches to the stand - by bat-

tery despite filled cylinder or

drum and opened connecting

valve.

CAUSE

●The gas dosing system is

leaky, so that the vacuum

required for the change - over

function cannot be gener-

ated.

●The change - over device is

coupled with a chlorine gas

dosing unit V 107 or V 115,

without having provided a

compensation for the main

regulator.

●The diaphragm (2) or o - ring

(3) in the change - over de-

vice are leaky.

●The vacuum regulator lets

through only an insufficient

amount of chlorine or the

vacuum line is too long (this

fault occurs mainly with a

high flow rate). It can also be

the case that a chlorine cyl-

inder is frozen up.

●Using the change - over de-

vice in connection with the

vacuum regulator C 105-230

(all vacuum system) the flow

rate of each regulator can

exceed 600 g/ h or 30 PPD.

DISCERNIBLE FROM

☞The rotameter indicates a

flow, although the supply bat-

tery (cylinder, drum) is empty

or closed.

☞The vacuum of 2 - 3 m WS /

52" - 78" WC required for the

change - over function is not

attained (measure the vacu-

um between change - over

device and regulator with a

vacuum meter).

☞The rotameter indicates a

flow, although the supply bat-

tery (cylinder, drum) is empty

or closed.

☞Measure the vacuum after

the outlet of the change -

over device with a vacuum

meter. The vacuum must

amount to less than 2 m WS /

52" WC.

☞Measure the vacuum after

the outlet of the change -

over device with a vacuum

meter. The vacuum has to

be less than 2 m WS / 52" WC.

Adjust a smaller flow rate, so

that the value of the operat-

ing vacuum falls below that

of the vacuum required for

the change - over function.

CORRECTION

☞Check the dosing system for

leaks. For this purpose dis-

connect the vacuum lines

between the rotameter and

the vacuum regulators one

after the other, close them

with the finger and observe

the rotameter. See sections

5.1 and 5.2 Leak test.

☞Arrange a compensation for

the main regulator.

☞Replace the defective parts.

☞Clean the vacuum regulator

and restart it or lay a vacuum

line with a larger cross sec-

tion.

☞Add a further vacuum regu-

lator with chlorine cylinder to

the supply battery, if the

maximum flow rate is re-

quired.

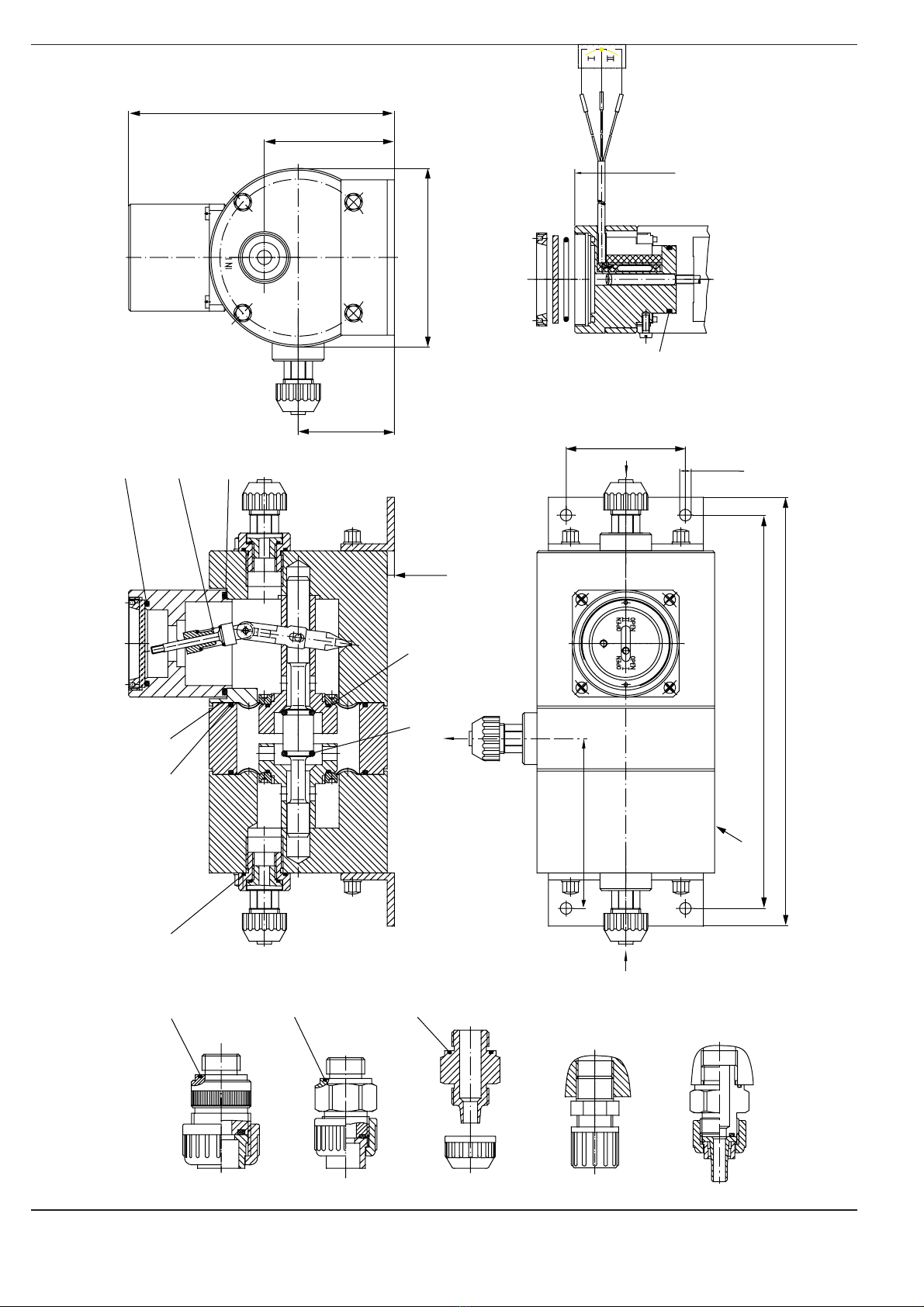

7 Spare Parts Set

There is a spare parts set, order no. 553-1024 available for

the vacuum change - over device U 189-010. It comprises the

o - rings (1 / 3 / 4 / 5 / 7 / 8 / 9), the diaphragm (2) as well as the

pressure spring (6). If other than the indicated parts are defec-

tive, return the change - over device to the works for repair or

replacement.