Stretching your $$$$

Most cuts will be done by pushing away from you and from side-to-side. This will dull the diamond on the blade front and sides,

but leave the back relatively sharp. By loosening the Blade Chuck’s 7/16” nut and turning the blade 180 degrees, you can

extend your useful blade life.

Note that the blade should never be installed upside-down. To do so will drastically shorten your guide and Blade Chuck life.

Just like a band saw, or any other diamond tool, these blades will become dull from use and you will have to push harder to

make cuts. Pushing extremely hard can break your blade. Finally the blade will need to be replaced. The beauty of the Gryphon

Wire Saw is that the blades are inexpensive. 15 of the Wire Saw blades cost the same a one band saw blade, but 15 Wire Saw

blades will cut nearly twice as much glass under normal use as one band saw blade.

Replacement blades are offered in a choice of three grits. The Super Power blade is the best all-around choice for general cutting, but you can chose a ner or coarser

grit blade depending upon your application.

The Ultra Power blade has the largest diamond particles, and cuts the fastest. It is recommended for difcult glass, tile and stone, or where speed is important. This

blade also has the longest life.

The Power blade offers the nest diamond particles and provides the smoothest surface nish.

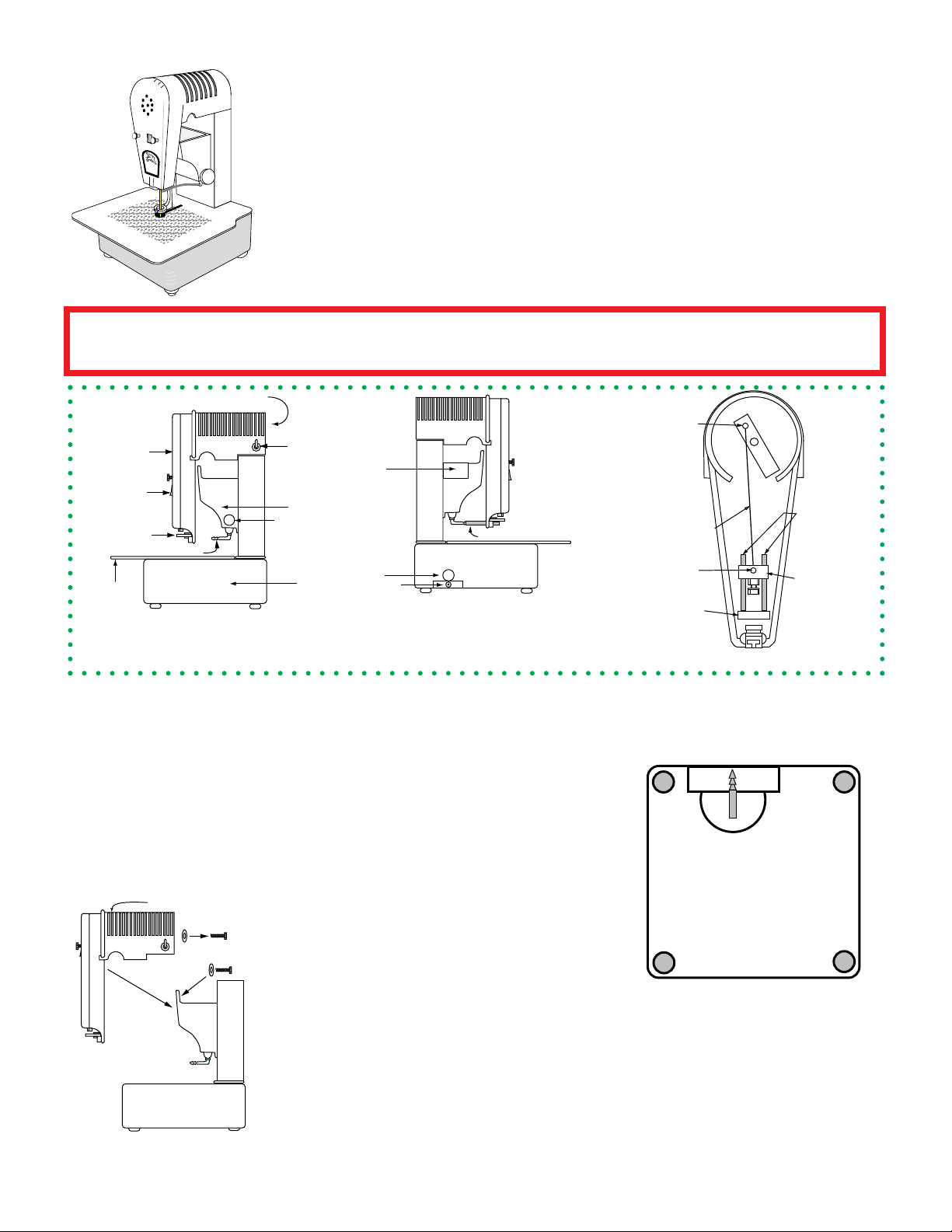

Changing parts

Blade guides pull straight out toward the saw front. They snap in place, so expect a little resistance when

removing and replacing them. Replace the guides when the blade hole becomes sloppy. Note that the

upper and lower blade guides are not interchangeable.

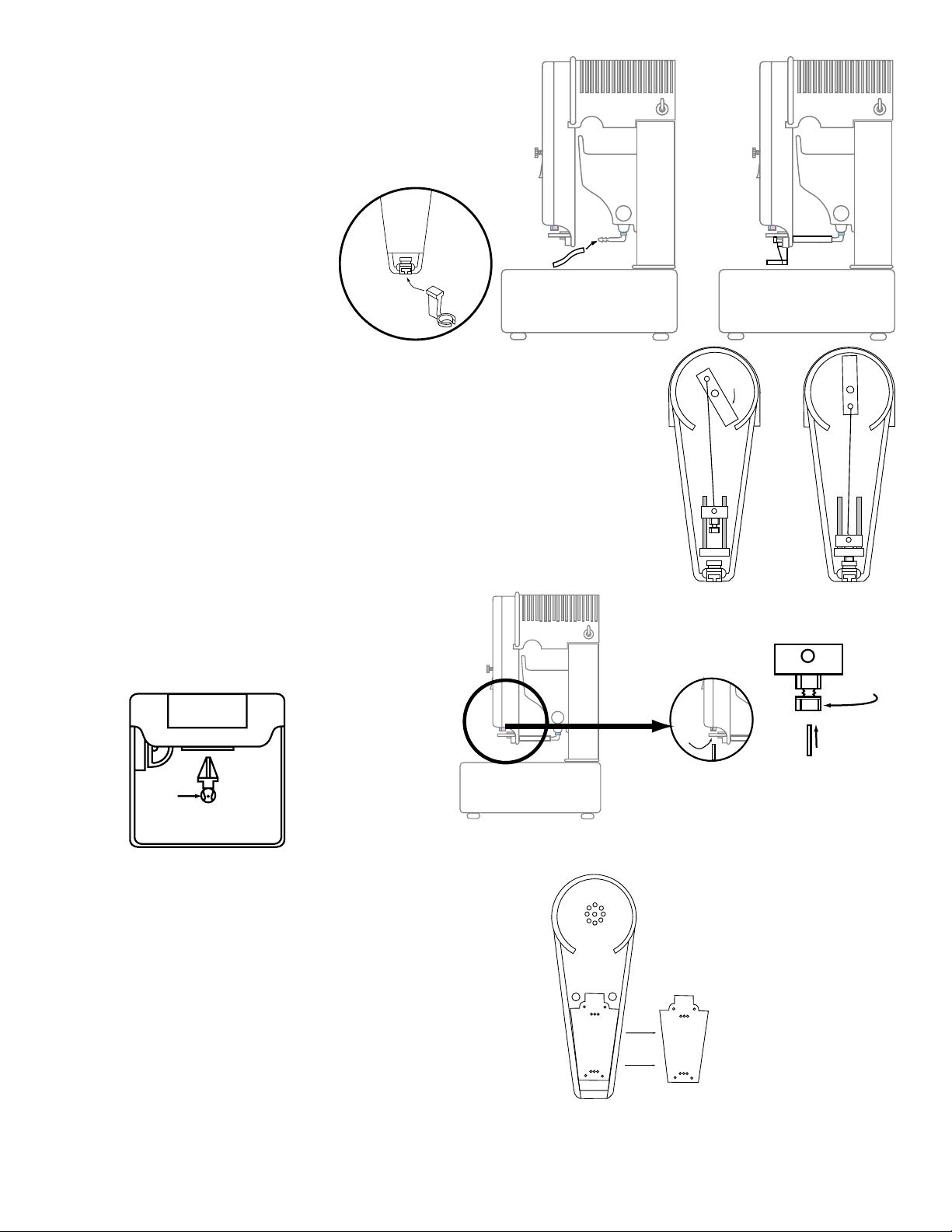

If the blade chuck wears from use the saw will become quite loud when running. To change:

1. Remove blade.

2. Loosen set screw in upper wrist pin.

3. Slide connecting rod out of upper wrist pin.

4. Pull connecting rod and blade chuck up and out of saw.

5. Loosen set screw in lower wrist pin and pull out connecting rod.

6. Put the wrist pin into a new blade chuck.

7. Push connecting rod into lower wrist pin hole until it stops, then tighten set screw.

8. Replace assembly onto the two vertical shafts and thread connecting rod into the upper wrist

pin.

9. Turn the rotor to down position as shown in the diagram to the right.

10. Insert the thin (gauge) end of your chuck wrench between the top of the aluminum block and

the blade chuck.

11. Push the blade chuck downward until the chuck wrench is held snugly.

12. Tighten the set screw on the upper wrist pin and remove

the chuck wrench. Oil both vertical shafts to complete the

replacement.

Unclogging the drain line

Usually wiping the end of the drain line and blowing into it will clear debris from the passage. Occasionally you may need to remove the barbed tting and clean it with

a needle.

Vertical

Shafts

Blade

Chuck

Connecting

Rod

Aluminum

Block

Lower

Wrist

Pin

Upper

Wrist

Pin

Thin (gauge) end of wrench

Chuck Wrench

Warranty

Your new Gryphon Diamond Wire Saw is warranted for one year from date of purchase. All mechanical parts with the exception of the

blade and blade guides are guaranteed against failure for one year. If such a failure occurs for any reason other than abuse or misuse

during this period, it will be repaired (or at our option replaced) free of charge FOB our factory. Retain your sales receipt for proof of

purchase. Should repairs ever be required, return the saw to Gryphon Corporation.

© 2003 Gryphon Corporation • 12417 Foothill Blvd. • Sylmar • California • 91342 • (818) 890-7770 • www.gryphoncorp.com