Table of Contents

PNEG-119 Inline Centrifugal Fan 3

Contents

Chapter 1 Safety .....................................................................................................................................................4

Safety Guidelines .................................................................................................................................. 4

Cautionary Symbols Definitions ............................................................................................................ 5

Safety Cautions ..................................................................................................................................... 6

Safety Sign-Off Sheet ......................................................................................................................... 10

Chapter 2 Safety Alert Decals .............................................................................................................................11

Fan Decals .......................................................................................................................................... 12

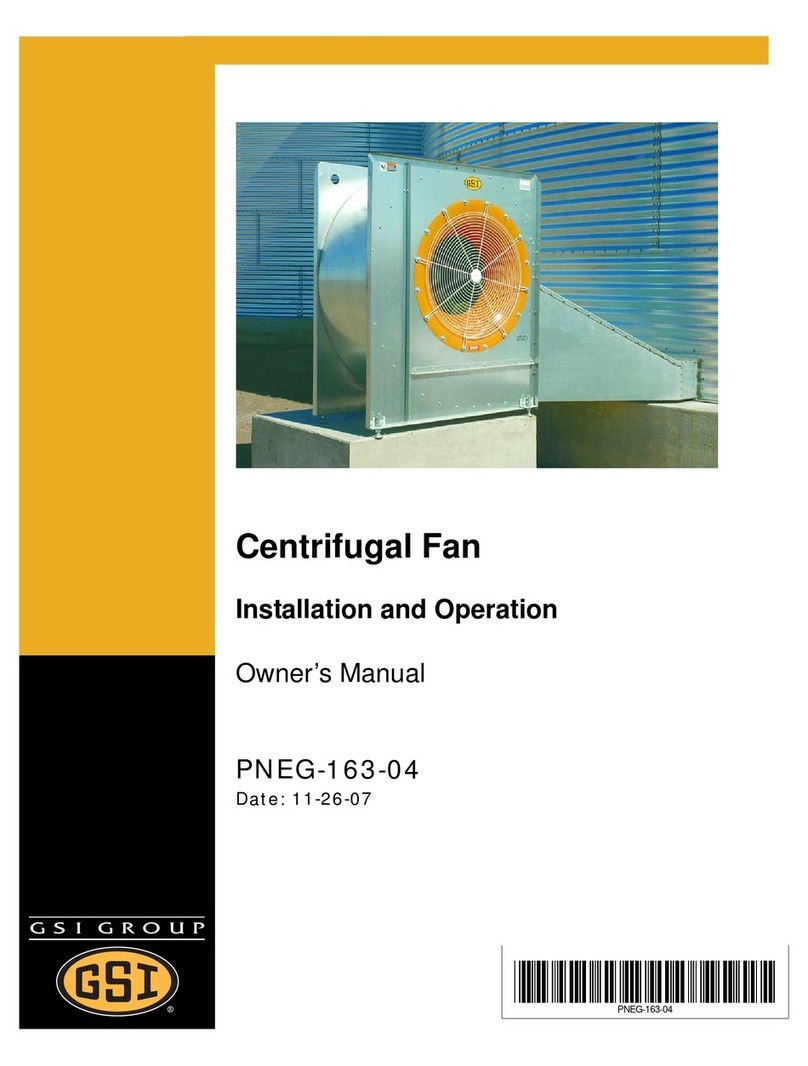

Chapter 3 Installation Instructions .....................................................................................................................13

Fan Pad Location ................................................................................................................................ 13

Check List before Installing the Fan .................................................................................................... 13

Installation ........................................................................................................................................... 14

Chapter 4 Fan Specifications ..............................................................................................................................15

Chapter 5 Fan Installation ...................................................................................................................................17

Previously Installed Units .................................................................................................................... 17

Machine to Earth Ground .................................................................................................................... 17

Proper Installation of the Ground Rod ................................................................................................. 18

Chapter 6 Fan Operation .....................................................................................................................................19

Start-Up ............................................................................................................................................... 19

Maintaining Grain Quality .................................................................................................................... 19

Grain Storage ...................................................................................................................................... 19

Chapter 7 Fan Service .........................................................................................................................................21

Relubrication Intervals (Motors with Regressing Capability) ............................................................... 21

Lubricant ............................................................................................................................................. 21

Procedure ............................................................................................................................................ 21

Chapter 8 User Servicing Instructions and Troubleshooting ..........................................................................22

Fan Wheel Removal and Installation .................................................................................................. 22

Removing the Fan Wheel Assembly ................................................................................................... 22

Installing the Fan Wheel Assembly ..................................................................................................... 23

Troubleshooting .................................................................................................................................. 26

Chapter 9 Parts List .............................................................................................................................................27

18"-28" Inline Parts ............................................................................................................................. 27

Chapter 10 Wiring Diagrams ...............................................................................................................................28

1 Phase 230 Volt Schematic ............................................................................................................. 28

1 Phase 230 Volt Wiring Diagram and Parts ..................................................................................... 29

3 Phase 230 Volt Schematic ............................................................................................................. 30

3 Phase 230 Volt Wiring Diagram and Parts ..................................................................................... 31

3 Phase 460 Volt Schematic ............................................................................................................. 32

3 Phase 460 Volt Wiring Diagram and Parts ..................................................................................... 33

3 Phase 575 Volt Schematic ............................................................................................................. 34

3 Phase 575 Volt Wiring Diagram and Parts ..................................................................................... 35

Chapter 11 Warranty ............................................................................................................................................37