PNEG-163-04 Centrifugal Fan 3

Table of Contents

Contents

Chapter 1 Safety .................................................................................................................................. 5

Safety Guidelines ................................................................................................................ 5

Safety Decals ...................................................................................................................... 8

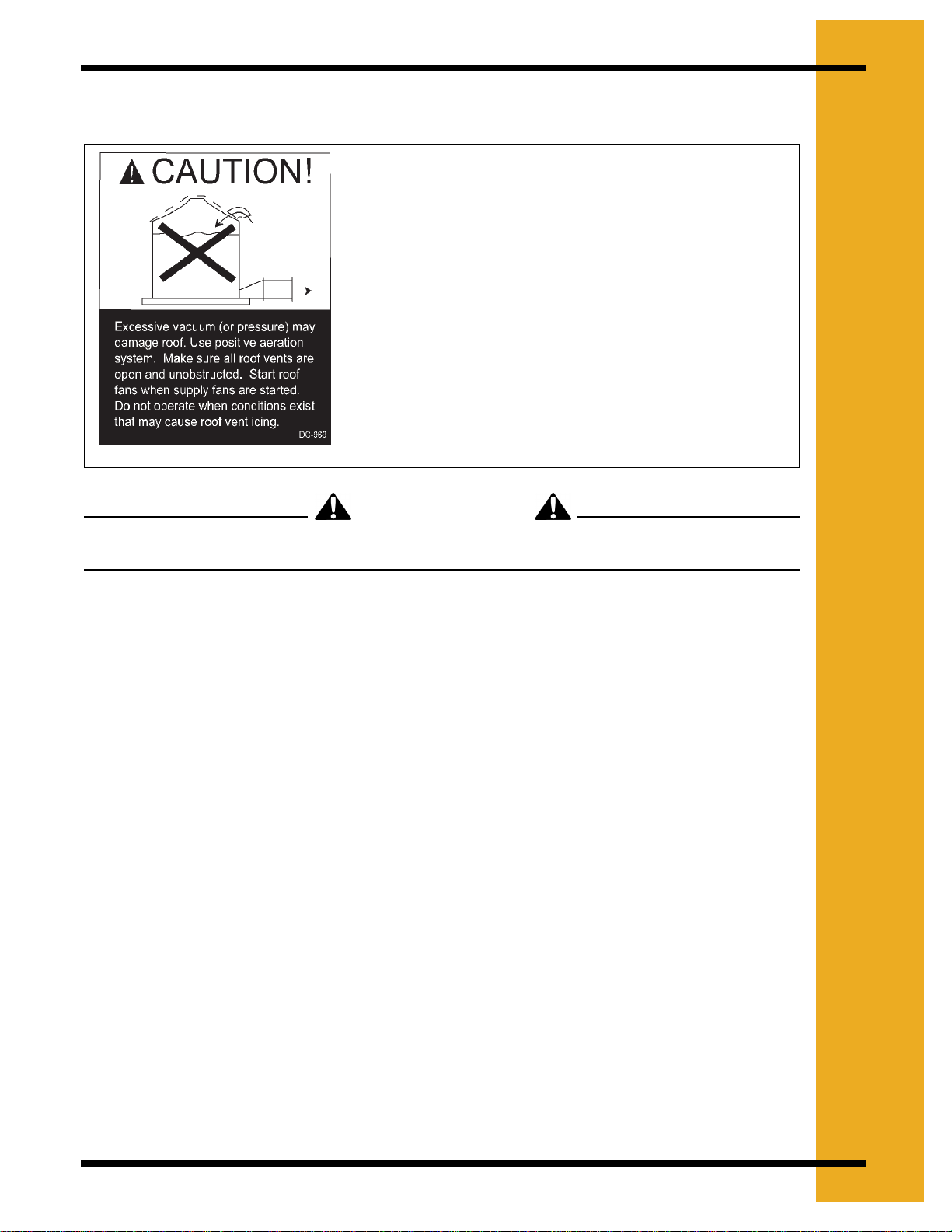

Roof Damage Warning and Disclaimer ............................................................................... 9

Chapter 2 Installation ....................................................................................................................... 10

Pre-Installation Requirements ........................................................................................... 10

Fan Installation .................................................................................................................. 11

Electrical Installation ......................................................................................................... 11

Test Run ............................................................................................................................ 12

Ground Rod Installation .................................................................................................... 13

Chapter 3 Fan Specifications ........................................................................................................... 14

1750 rpm Fan Electrical Specifications ............................................................................. 14

3500 rpm Fan Electrical Specifications ............................................................................. 15

Fan Dimensions ................................................................................................................ 16

Discharge Bolt Pattern Dimensions .................................................................................. 17

Inlet Cone Dimensions ...................................................................................................... 18

Fan Wheel Dimensions ..................................................................................................... 19

Fan Pad Location .............................................................................................................. 20

Chapter 4 Operation ......................................................................................................................... 21

Fan Start-Up ...................................................................................................................... 21

Fan Shut-Down ................................................................................................................. 21

Maintaining Grain Quality .................................................................................................. 21

Grain Storage .................................................................................................................... 22

Chapter 5 Maintenance and Troubleshooting ................................................................................ 23

Fan Wheel Removal & Installation .................................................................................... 23

Fan Wheel Inspection & Maintenance .............................................................................. 24

Taper Bushing Torque Requirements ............................................................................... 25

Fan Motor Removal & Installation ..................................................................................... 25

General Inspection ............................................................................................................ 25

Lubrication & Bearings ...................................................................................................... 26

Troubleshooting Charts ..................................................................................................... 27

Chapter 6 Parts ................................................................................................................................. 29

Main Assembly - 1750 rpm Fans ...................................................................................... 30

Main Assembly - 3500 rpm Fans ...................................................................................... 35

Main Assembly - Single Inlet Direct Drive Fan .................................................................. 40

Main Assembly - Double Inlet Fan .................................................................................... 41

Internal Bearing Arch Assembly - Double Inlet Fan .......................................................... 42

Motor Drives - Double Inlet Fan ........................................................................................ 43

Shaft Coupling ................................................................................................................... 44

Control Box Sub - Assembly ............................................................................................. 45

Control Box Assembly - Single Phase 230 Volt ................................................................ 46

Control Box Assembly - Three Phase 230 Volt ................................................................. 47

Control Box Assembly - Three Phase 460 Volt ................................................................. 51

Motor Conduit Assembly ................................................................................................... 56