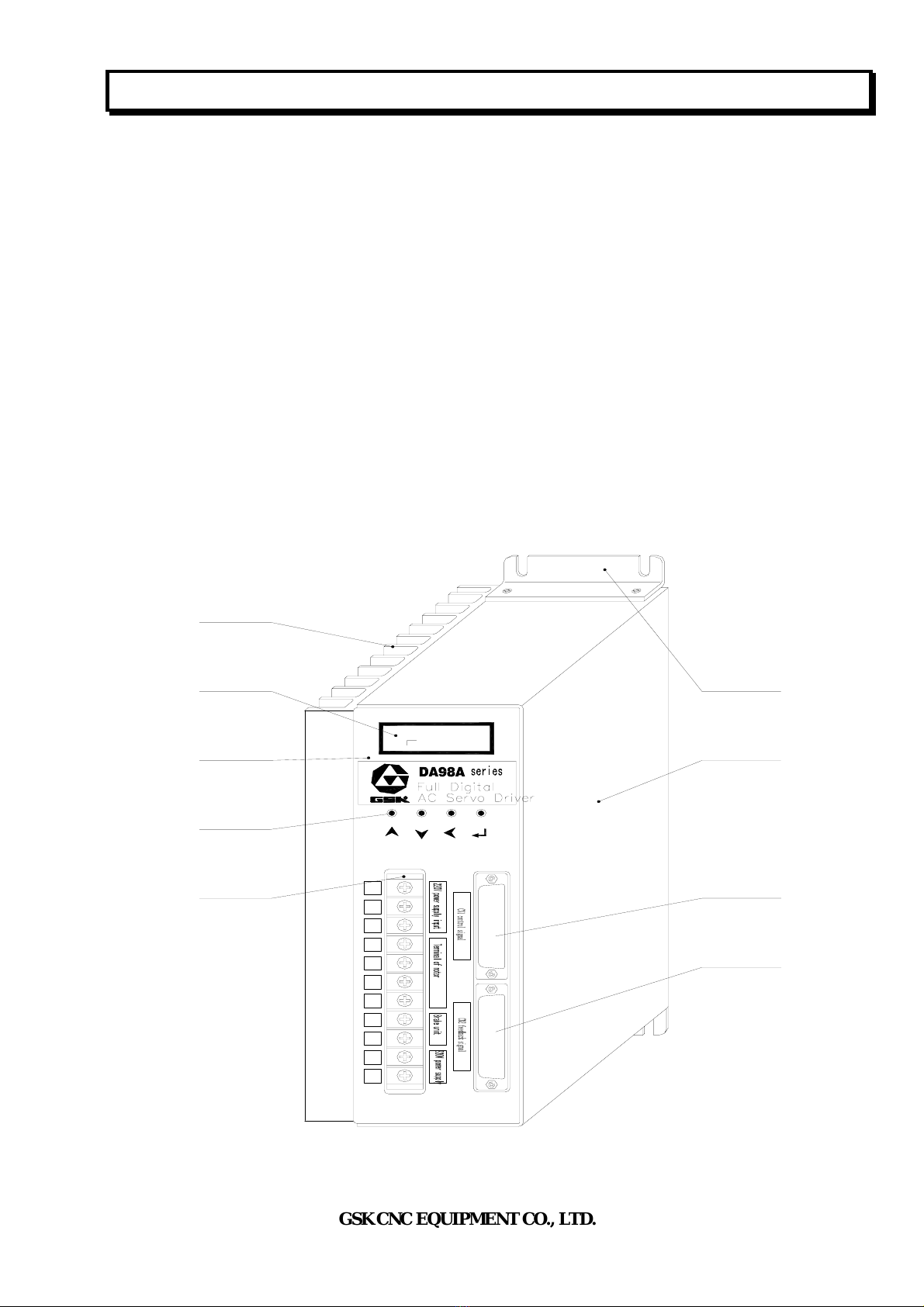

DA98A User Manual

V

Contents

Overview............................................................................................................................................1

1.1 Introduction................................................................................................................................1

1.2 Check after delivery.................................................................................................................2

1.3 Outline..........................................................................................................................................3

Installation.......................................................................................................................................5

2.1 Environmental condition........................................................................................................5

2.2 Installation of servo driver.....................................................................................................5

2.3 Installing servomotor...............................................................................................................7

Wiring...................................................................................................................................................9

3.1 Standard wiring.........................................................................................................................9

3.2 Terminal function....................................................................................................................11

3.3 I/O Interface method.............................................................................................................14

Parameter.......................................................................................................................................17

4.1 Parameter list...........................................................................................................................17

4.2 Parameter function.................................................................................................................18

4.3 Type code parameter and motor........................................................................................22

Alarm and troubleshooting..............................................................................................24

5.1 Alarm list...................................................................................................................................24

5.2 Alarm troubleshootings.........................................................................................................25

Display and operation..........................................................................................................30

6.1 Keyboard operation...............................................................................................................30

6.2. Monitoring mode...................................................................................................................30

6.3 Parameter setting....................................................................................................................33

6.4 Parameter management........................................................................................................34

6.5 Speed trial run.........................................................................................................................36