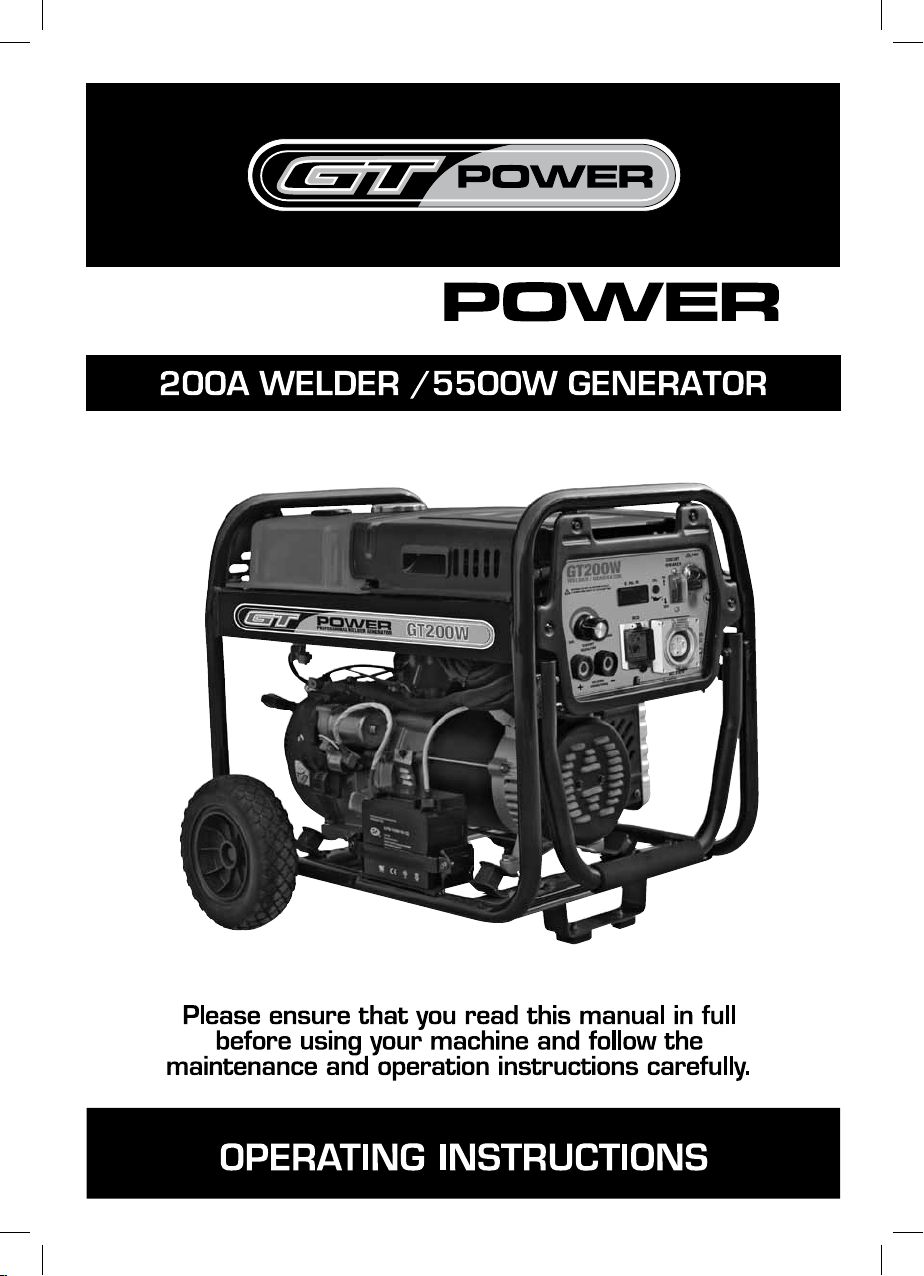

GT200W PROFESSIONAL WELDER GENERATOR

7.

www.gtpower.co.nz

WARNING: Do not attempt to use this

equipment until you have thoroughly

read all operating and maintenance

manuals supplied with your machine.

They include important safety precau-

tions, detailed engine starting, operat-

ing and maintenance instructions, and

parts lists.

Hazards of Electric Shock, Engine

Exhaust & Moving Parts

ELECTRIC SHOCK can kill.

• DO NOT touch electrically live parts

or electrode with skin or wet clothing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or vent

exhaust outside.

• Do not stack anything on or near the

engine.

MOVING PARTS can injure.

• Do not operate with doors open or guards

off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualied personnel should install, use,

or service this equipment.

Location & Ventilation

Whenever you use the GT200W, be sure

that clean cooling air can ow around the

machineʼs gasoline engine and the genera-

tor. Avoid dusty, dirty areas. Also, keep the

machine away from heat sources. Do not

place the back end of the generator any-

where near hot engine exhaust from another

machine. And of course, make sure that en-

gine exhaust is ventilated to an open, outside

area.

The GT200W must be used outdoors. Do not

set the machine in puddles or otherwise sub-

merge it in water. Such practices pose safety

hazards and cause improper operation and

corrosion of parts.

Always operate the GT200W with the case

roof on and all machine components com-

pletely assembled. This will help to protect

you from the dangers of moving parts, hot

metal surfaces, and live electrical devices.

CAUTION:

GASOLINE FUEL ONLY - Use in well

ventilated areas or vent exhaust outside

Storage

1. Store the machine in a cool, dry place

when it is not in use. Protect it from dust

and dirt. Keep it where it can not be acci-

dentally damaged from construction activ-

ities, moving vehicles and other hazards.

2. If you will be storing the machine for over

30 days, you should drain the fuel to pro-

tect fuel system and carburetor parts from

gum deposits. Empty all fuel from the tank

and run the engine until it stops from lack

of fuel.

3. You can store the machine for up to 24

months if you use a stabilising additive in

the fuel system. GT Power endorses Fuel

Set™ as the recommended brand of fuel

stabiliser to use and it is available from

your local GT Power Dealer. Mix the ad-

ditive with the fuel in the tank and run the

engine for a short time to circulate the addi-

tive through the carburetor.