Table of Contents

1. Safety Rules Page 1

2. Technical Specications Page 2

2.1 Generalspecications Page2

2.2 Electricalspecications Page2

3. General description Page 3

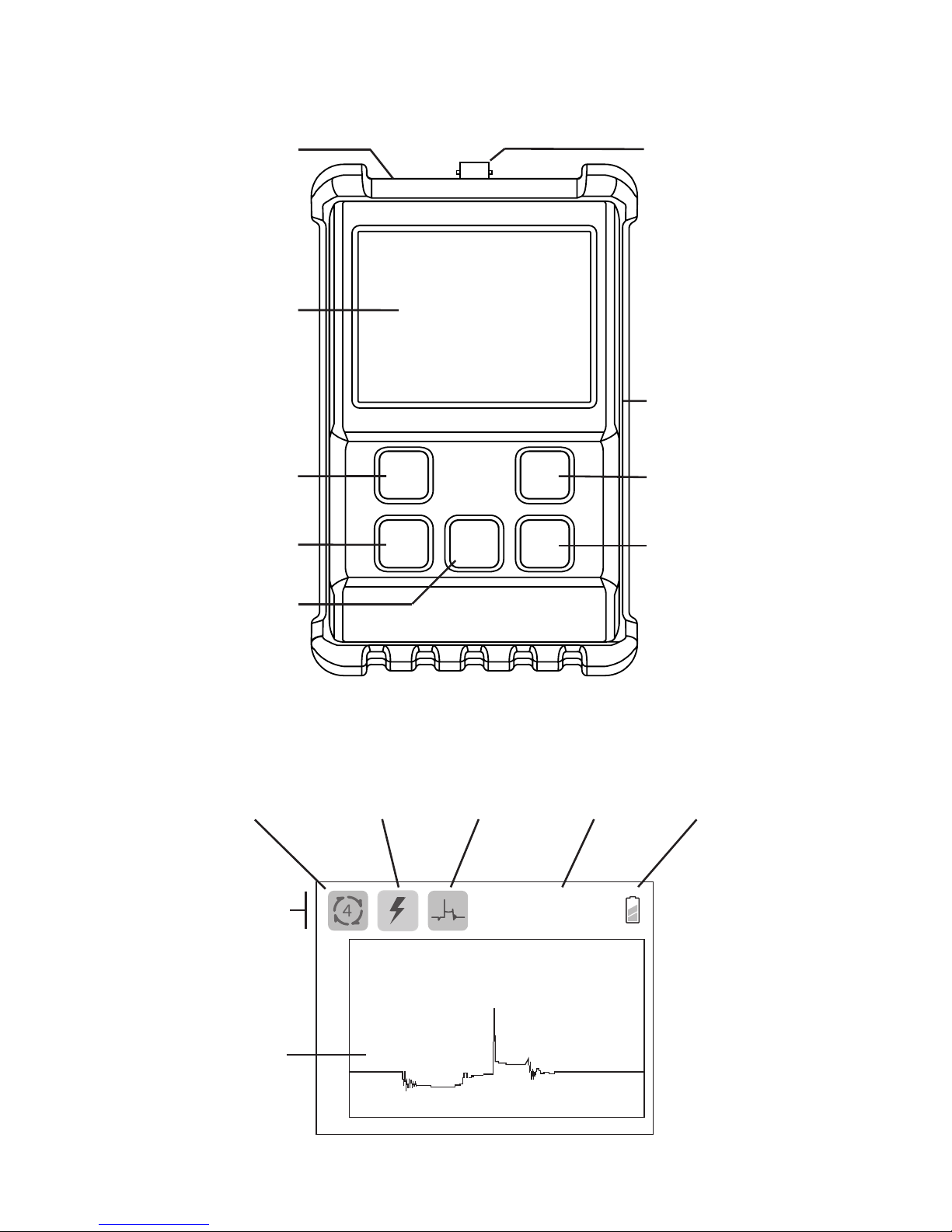

3.1 Instrumentdescription Page3

3.2Displaydescription Page3

4. Buttons, icons and menus operation Page 4

4.1POWER/CLEARbuttonandmenu Page4

4.2CYCLEbuttonandmenu Page4

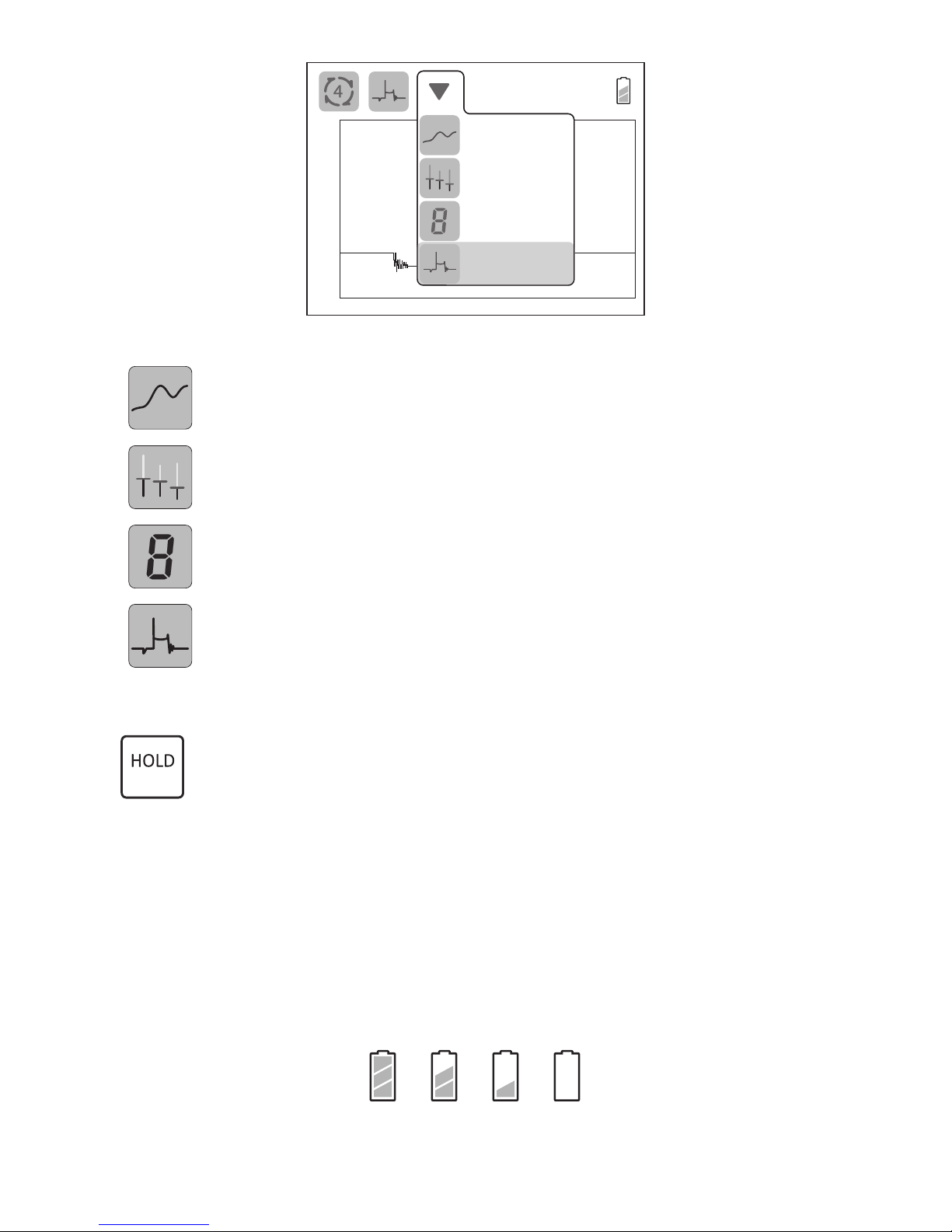

4.3 MODEbuttonandmenu Page5

4.4VIEWbuttonandmenu Page5

4.5HOLDbuttonandmenu Page6

4.6Tachometerreadings Page6

4.7Batterylevelindicator Page6

5. Measurement modes Page 7

5.1EngineRPM Page7

5.2Sparkburn(ring)time Page7

5.3 Sparkplugvoltage Page7

5.4Dwellangle Page7

5.5Ramptime Page7

6. Display views Page 8

6.1Chartview Page8

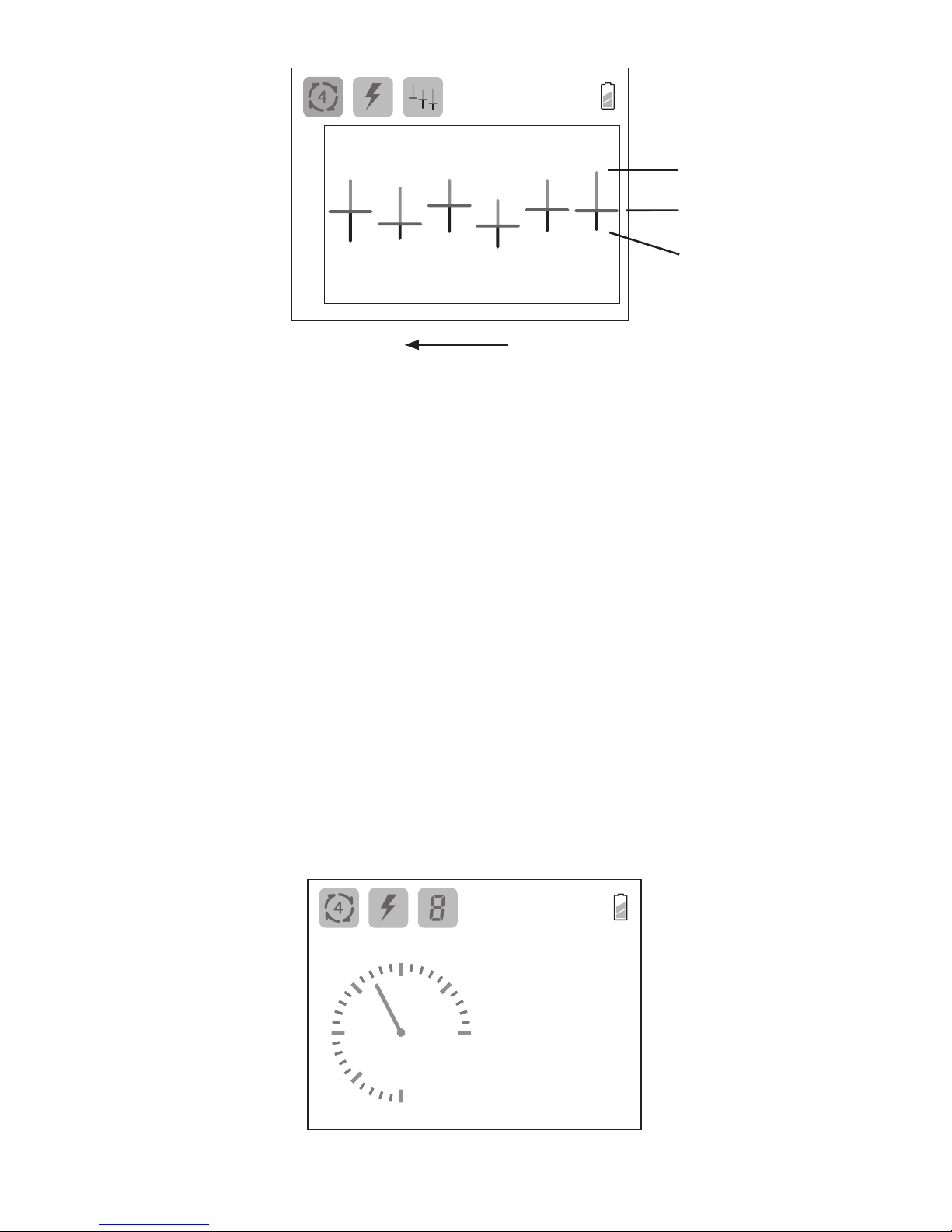

6.2Comparisonview Page8

6.3 Digitalview Page9

6.4WaveformView Page10

7. Measurement procedures Page 10

7.1Flexibleprobeandsensorsetup(GTC505andGTC505m) Page11

7.2Extensioncableandsensorsetup(GTC505monly) Page11

7.3Measuringcoilonplugandcoilnearplugignitionsystems Page11

7.4Measuringignitionsystemswithsparkplugwires Page12

8. Recharging the instrument Page 13

9. Maintenance Page 14

10. Warranty Page 14

1. SAFETY RULES

•Thisinstrumentisdesignedforindooruseattemperaturesbetween32°and104°F(0°Cand

40°C)andaltitudesupto6500ft.(2,000meters).

• Toensurethattheinstrumentisusedsafely,followallsafetyandoperatinginstructionsinthis

operationmanual.Iftheinstrumentisnotusedasdescribedinthisuser’smanual,thesafety

featuresofthisinstrumentmaybeimpaired.

• Donotusetheinstrumentiftheinstrument,thesensors,ortheexibleprobelookdamaged,

orifyoususpectthattheinstrumentisnotoperatingproperly.

• Whenusingtheinstrument,keepawayfrommovingparts(fan,drivebelts,etc)andhotobjects

(exhaustpipes,mufer,catalyticconverter,etc),toavoidpersonalinjuriesanddamagetothe

instrument,thesensors,exibleprobeandextensioncable..

• Donotconnecttheinstumenttoanythingotherthanthesensors,exibleprobe,extension

cable,USBcable,orACpoweradapterprovided.

• Atalltimes,toavoidelectricalshock,useCAUTIONwhenworkingwithelectricalcircuitsabove

60VDCor25VACrms.Suchvoltagesposeashockhazard.

• DonotoperatethisinstrumentwhileconnectedtotheACpoweradaptororanyotherdevice.

• Toavoidelectricalshockordamagetotheinstrument,donotexceedthespeciedinputlimits.

Exceeding the limits listed above when using this apparatus, or not observing the

precautions listed above can expose you to physical injury and permanently damage

your instrument and/or parts and components of the vehicle under test.