•Connect the test leads to the fault code signal pins of the diagnostic

socket and then trigger the fault code output.

•Typical fault code output triggering procedure is to short (close

circuit) the two trigger pins of the diagnostic socket and then turn

the ignition key to the ON position. DO NOT start the engine.

•Location of the diagnostic socket, signal pins assignment, signal

type, and procedures of triggering & clearing the fault code may

be varied with car models. Consult your vehicle service manual

for manufacturer's specifications. The display indicates a symbolic

pulse and the beeper turns on when the blink code pulse is

detected.

•Time interval between pulse signals and duration of pulse signal

represent the blink type fault code numbers.

•As an example, some car manufacturers use long pulse for the first

code digit, and short pulse for the second code digit. In this case,

2 long 'Beeps' followed by 5 short 'Beeps' represented fault code

number 25. As another example, some car manufacturers use

same time interval between pulse signals on the same code digit,

and with longer time interval to separate the code digits. In this

case 2 short 'Beeps' followed by a quiet interval and then followed

by 5 short 'Beeps' represented fault code number 25.

•Please note that in some car models, fault code signal output is

preceded by leading pulse signals.

•As a typical procedure for clearing the fault code stored in the

memory. Turn the ignition key to the OFF position. Disconnect the

negative ( ) battery terminal from the car electrical system for

about 1 minute, and the fault code will be cleared from memory.

Some car models require specific procedure to clear the fault code

stored, consult your vehicle service manual for details.

4.3.12 DTC-DECODER Function

6- Trigger the DTC readout by Shorting (close circuit) the 2 signal

pins of the data link connector for about 4 seconds until the

secondary LCD shows " ". Then the meter is ready to scan

the DTC readout automatically.

7- During scanning the meter secondary display indicates a pulse

symbol " ", and the beeper turns on when a DTC pulse is

detected.

If the DTC scanning is not successful, the meter secondary

display will indicate " " to alert the user. Re-check the wire

connections, and start the trigger process again.

If the DTC scanning is successful, the meter secondary display

will indicate code " " with 4 beep sounds, and the main

display indicates the correct DTC readout.

8- Read and note DTC readout displayed on the LCD Display "1" =

no fault stored, Greater than "1" = fault in system.

9- Repeat procedure in step 6. If there are no further faults in the

system, the previously displayed DTC will be displayed.

10- Repeat procedure in step 9 until the first DTC displayed is

repeated.

11- Eliminate (repair) all noted faults (DTC readout) of the car

according to troubleshooting chart and diagnostic tests.

12- After eliminating a fault, the respective DTC may be cleared

by repeating procedure on step 6 to get the DTC readout, and

then short the 2 signal pins for another 6 to 10 seconds, then

the DTC displayed is cleared. Please note that each DTC

displayed must be cleared individually.

*Note: Consult your Mercedes Benz Diagnostic Trouble Code

Reference Guide for signal pins assignments and engine

precondition procedures before triggering the DTC readout. They

might be different from car model to model, and function to function.

5. ADVANCED OPERATION

See table below for feature availability on each function.

Function Data

Hold Range

Lock 40,000

Count Relative Record Crest

(Peak) +/-

Trigger Trigger

Level No. of

Cylinders Dual

Display Store

Recall

DC Voltage •••••• ••

AC Voltage •••••• ••

Temperature ••• ••

DC Current •••••• •

AC Current •••••• •

Resistance ••••• •

RPM •••• •

Frequency ••••••

Duty Cycle •••••••

-ms •••••••

Dwell •••••••

O2 Sensor •••

Continuity •••• •

Diode •••• •

Alternator Test •••

Fault Code •••

DTC Decoder •••

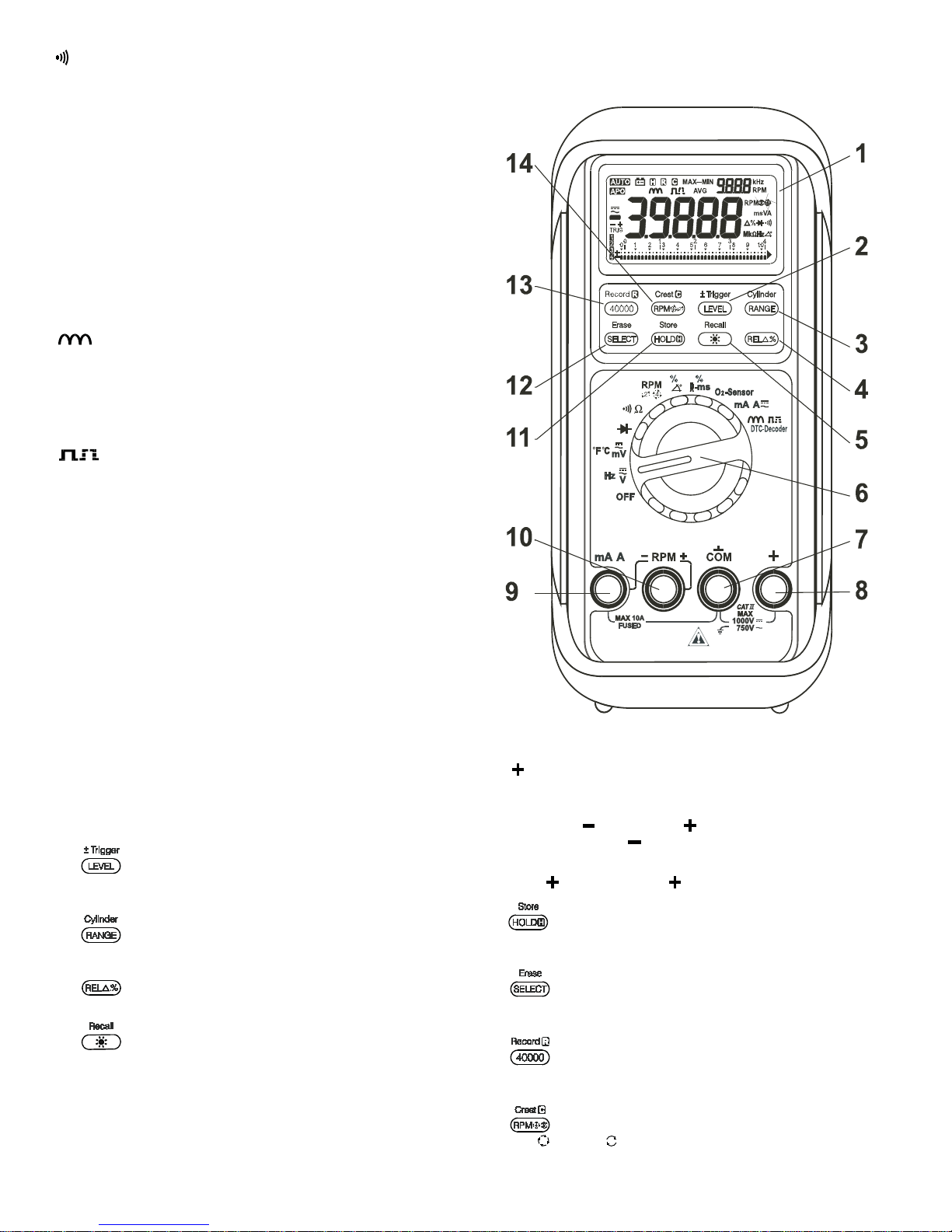

5.1 40,000 COUNTS HIGH RESOLUTION Mode

Press the button momentarily to enter the 4-3/4 digit high

resolution slow mode with a maximum display at 40,000 counts.

Press the button momentarily again to return to 3-3/4 digit fast

mode. In 3-3/4 digit fast mode, the digital display updates 5 times per

second nominal to give you the maximum measuring speed. In 4-

3/4 digit slow mode, the digit display updates 1.25 times per second

nominal to give you smooth readings as well as the full accuracy of

the meter.

1- Set rotary switch to DTC-Decoder

2- Default at . Press SELECT button two times to select

DTC-Decoder

3- Insert Red ( ) test lead into jack and black ( ) test lead

into COM input jack

4- *Connect the test leads to the signal pins of the data link

connector. This function is a replacement of the impulse counter

scan tool with wire connections COM for black (bk), and

for yellow (yw) as specified in the Mercedes-Benz Diagnostic

Trouble Code Reference Guide. Since the meter is powered by

internal battery, connection of the impulse counter red (rd) wire

(to B+) for external power is not required

5- *Set Engine at idle

Page 7