WARNING!

D

DO

ON

NO

OT

T:

:

•Do not alter or misuse this equipment.

•Do not use combinations of components or subsystems

that may affect or interfere with the safe, compatible

function of each other.

•Do not expose the equipment to chemicals which may

produce a harmful effect or degrade the equipment.

Consult manufacturer in cases where doubt exists.

•Do not use the equipment around moving machinery or

electrical hazards unless specifically designed for such

use.

•Do not use the equipment around sharp edges or

abrasive surfaces unless intended for such use.

DO NOT THROW AWAY THESE INSTRUCTIONS!

READ AND UNDERSTAND BEFORE USING EQUIPMENT!

This manual should be read and understood in its entirety, and used as part of a

training program as required by OSHA or any applicable state regulatory agency.

This and any other included instructions must be provided to the users of the

equipment. The user must understand the proper equipment use and limitations.

User must keep a copy of these instructions for reference and training.

This product meets all applicable OSHA and ANSI standards for fall protection.

G

GE

EN

NE

ER

RA

AL

LS

SY

YS

ST

TE

EM

MS

SE

EL

LE

EC

CT

TI

IO

ON

NC

CR

RI

IT

TE

ER

RI

IA

A:

:Selection of

fall protection shall be made by a Competent Person. All fall protection

equipment shall be purchased new and unused.

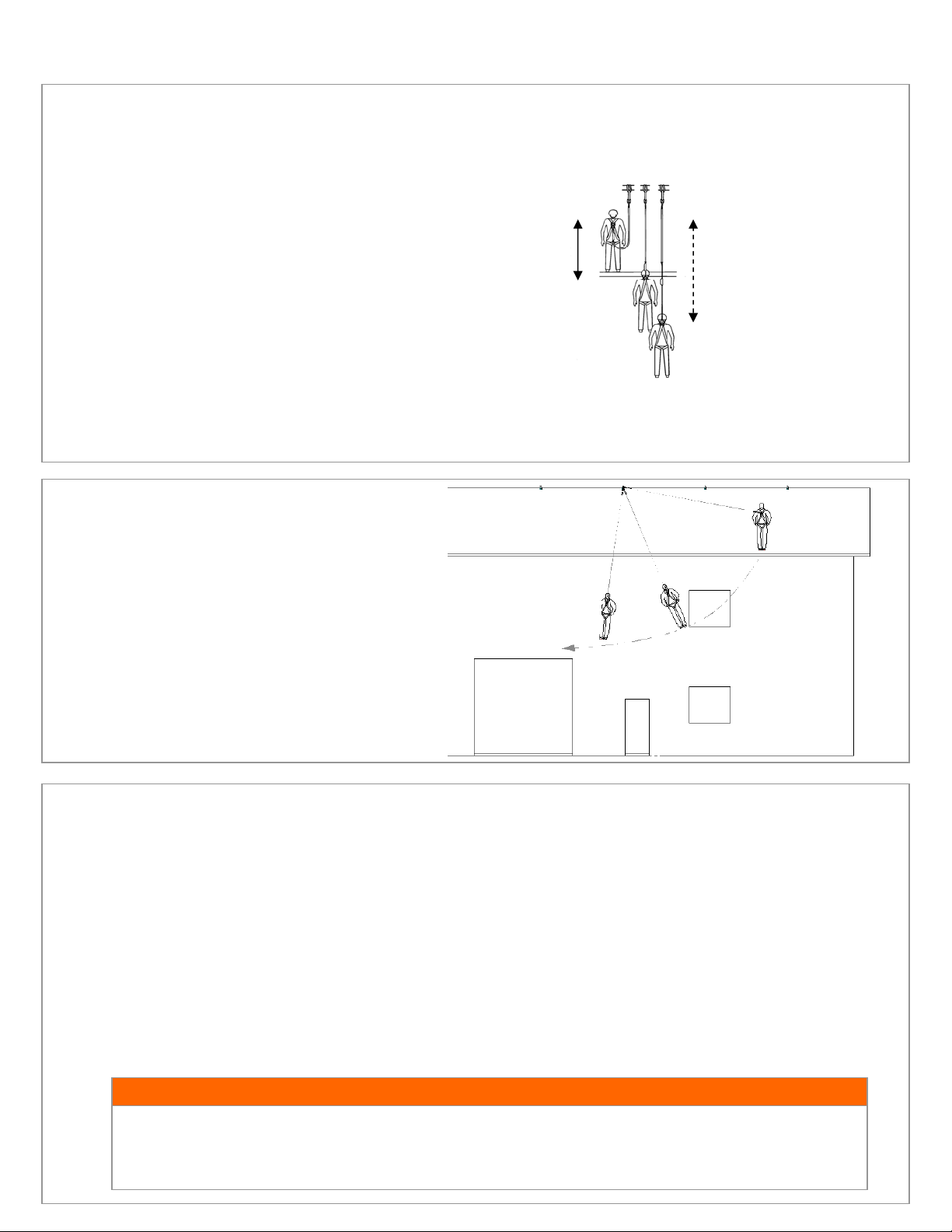

The equipment is designed for use as a part of a personal fall protection system.

Components shall not be used for any other operation other than that which it has

been designed and approved.

Fall Arrest Systems shall be designed to comply with OSHA or applicable state

regulatory limitations. Systems must be used in a compliant manner.

Fall Restraint systems shall be designed by a Qualified Person, and must be

installed and used under the supervision of a competent person.

Consult a doctor if there is any reason to doubt a user’s ability to withstand and

safely absorb fall arrest forces. Age, fitness, and health conditions can seriously

affect the worker should a fall occur. Pregnant women and minors should not

use this equipment.

T

TR

RA

AI

IN

NI

IN

NG

GR

RE

EQ

QU

UI

IR

RE

EM

ME

EN

NT

TS

S:

:The employer shall provide a training program for each employee who might be exposed to fall hazards. The

program shall enable each employee to recognize the hazards of falling and shall train each employee in the procedures to be followed in order to

minimize these hazards. Relevant Federal, State, and local regulatory requirements, procedures, and standards shall also be a part of training.

The employer shall ensure that each employee has been trained, as necessary, by a Competent or Qualified Person in the nature of fall hazards in the

work area, the correct erecting, maintaining, disassembling, and inspection of the fall protection systems being used, and the use of personal fall

arrest systems.

R

RE

ES

SC

CU

UE

EP

PL

LA

AN

N:

:The user is required to have a rescue plan and the means at hand to implement it when using the equipment. The plan shall be

project specific. Employees shall be trained in self-rescue or alternate means shall be provided for prompt rescue in the event of a fall.

I

IF

FE

EQ

QU

UI

IP

PM

ME

EN

NT

TI

IS

SS

SU

UB

BJ

JE

EC

CT

TE

ED

DT

TO

OA

AF

FA

AL

LL

L:

:Remove the equipment from service immediately if it has been subjected to the forces of a

fall arrest. Contact your distributor or Guardian about policies regarding replacement of Guardian components involved in a fall.

I

IN

NS

SP

PE

EC

CT

TI

IO

ON

N:

:

•Only the manufacturer of this equipment or persons or entities authorized in writing by the manufacturer shall make repairs to fall

protection equipment.

•Formal inspections shall be made by either a Competent or Qualified Person on at least a semi-annual basis.

P

PR

RI

IO

OR

RT

TO

OE

EA

AC

CH

HU

US

SE

E:

:

•Fall protection equipment shall be inspected by the user for defects, damage, or deterioration.

•Any suspected defective equipment shall be removed from service.

•If the manufacturer’s label is not legible or is missing, the equipment shall be removed from service. Fall protection equipment shall

be removed from service upon evidence of defects, damage, or deterioration, or upon expiration of the manufacturer’s specified

service limits, whichever comes first.

Arco Pod

Guardian Fall Protection Kent WA 98032

800.466.6385 www.guardianfall.com