i Contents

iContents....................................................................................................................................................2

ii References................................................................................................................................................2

iii Term Definitions & Acronyms..................................................................................................................2

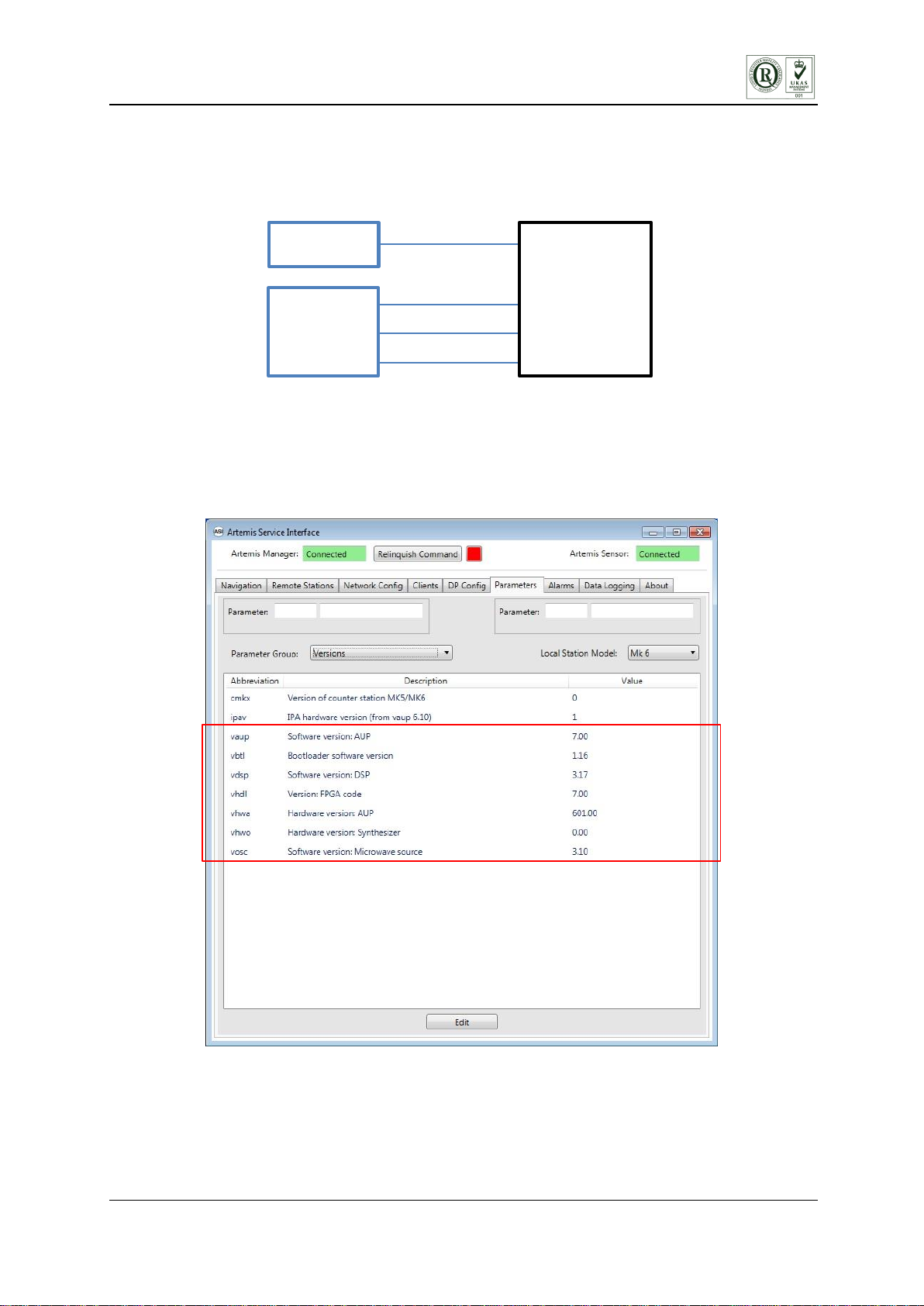

1. Artemis Software Versions.......................................................................................................................3

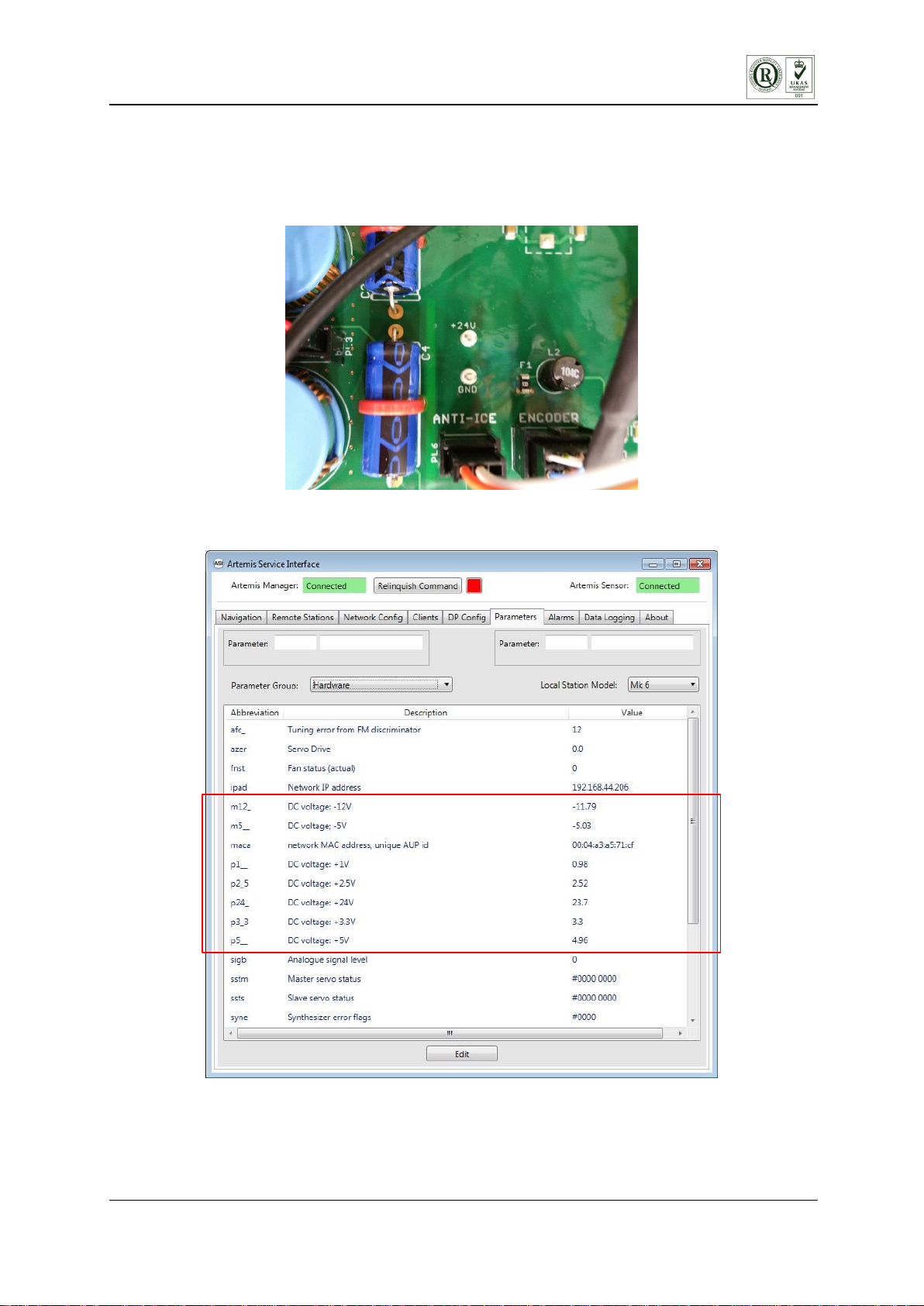

2. Voltage Measurements............................................................................................................................4

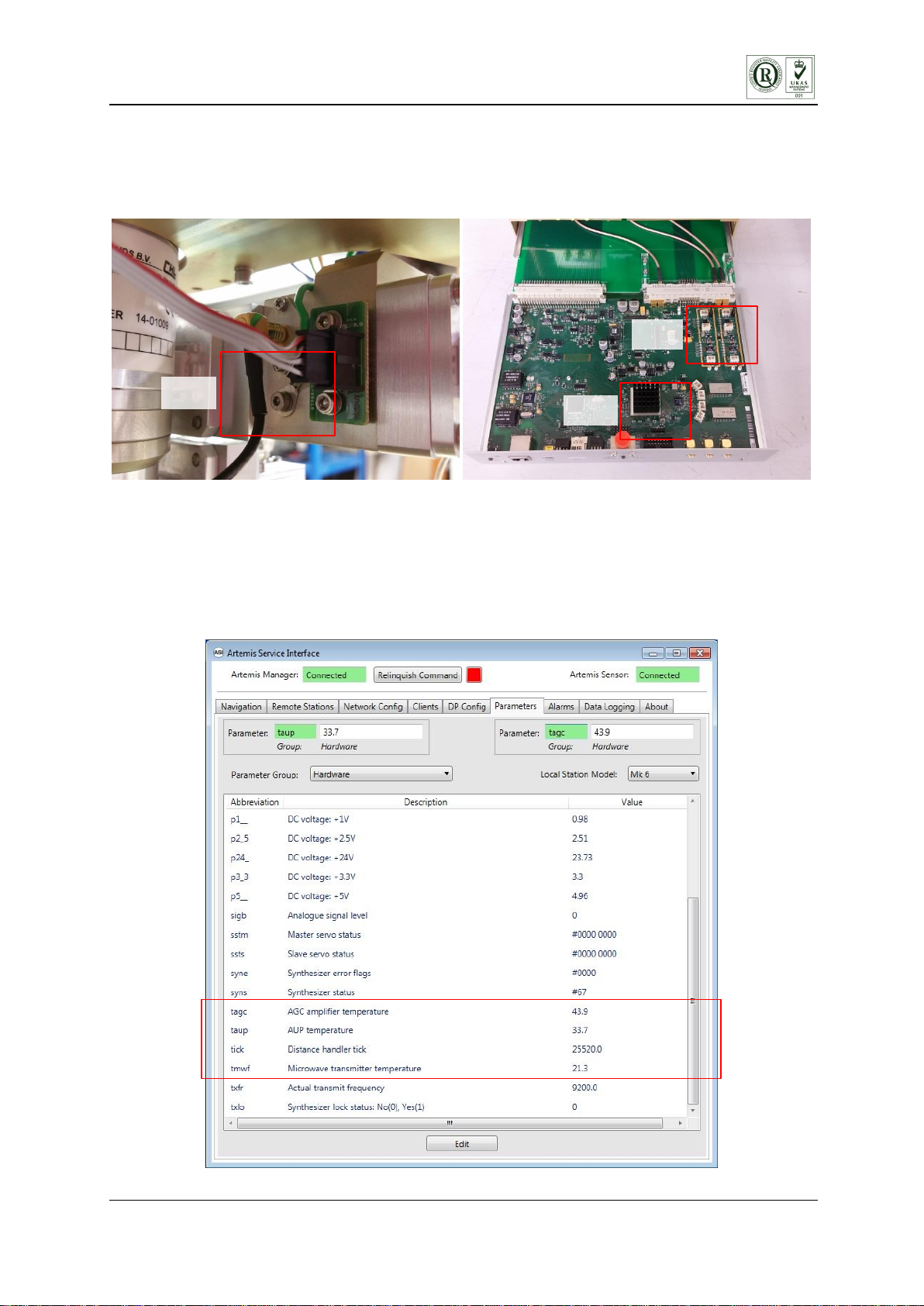

3. Temperature Sensors..............................................................................................................................5

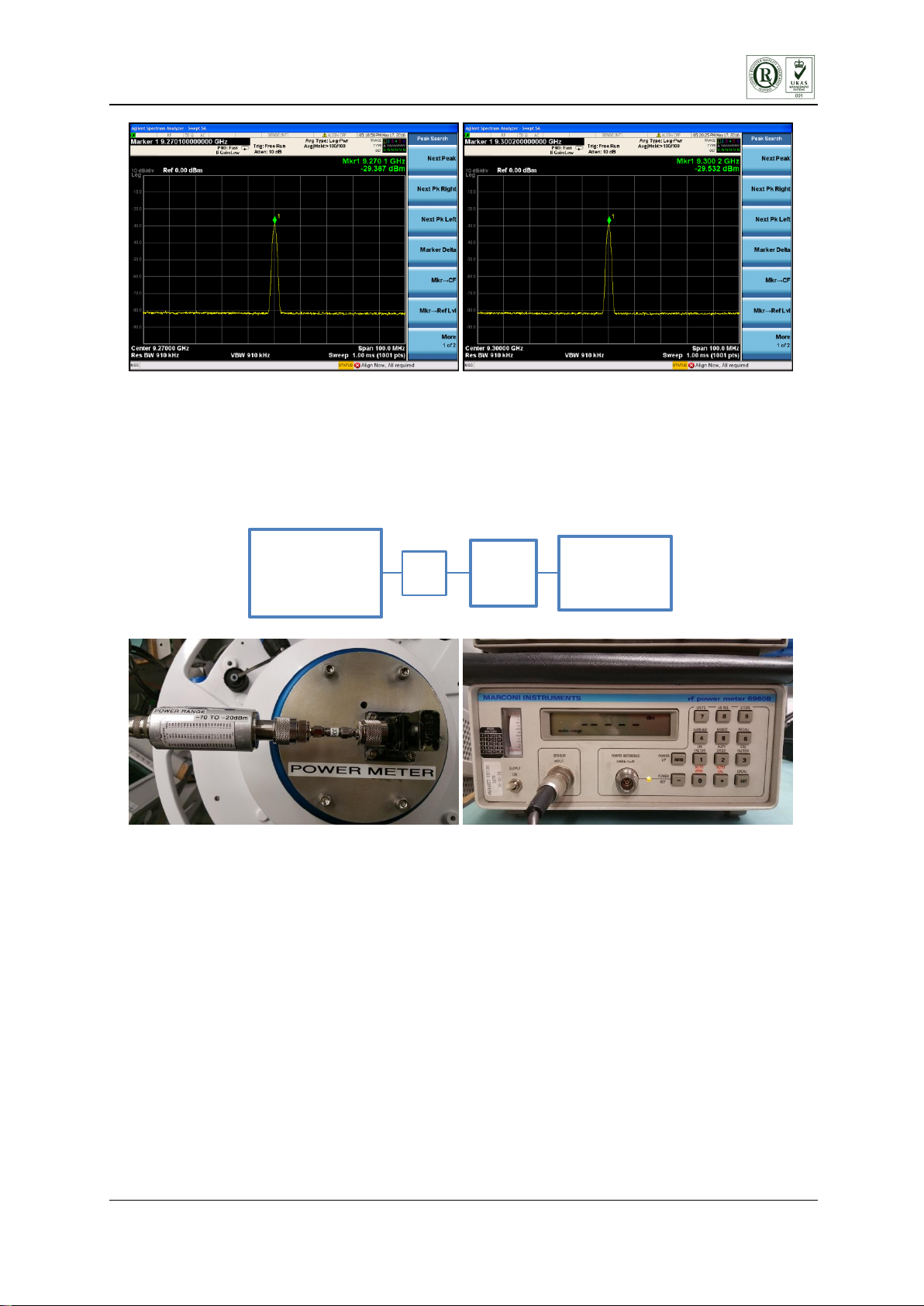

4. Microwave Output Characteristics...........................................................................................................6

5. IF Pre-Amp Gain and Noise Measurement............................................................................................8

6. AGC Amplifier.........................................................................................................................................10

7. Fixed Delay Adjustment.........................................................................................................................15

8. Anti-Icing.................................................................................................................................................18

9. Phase and Servo Test............................................................................................................................19

10. Encoder Readout ...................................................................................................................................21

ii References

WI G2 ESD Equipment Testing and Recording

Refer to production works order for latest revision of parts.

iii Term Definitions & Acronyms

Term Definition

ASI Artemis Service Interface (software)

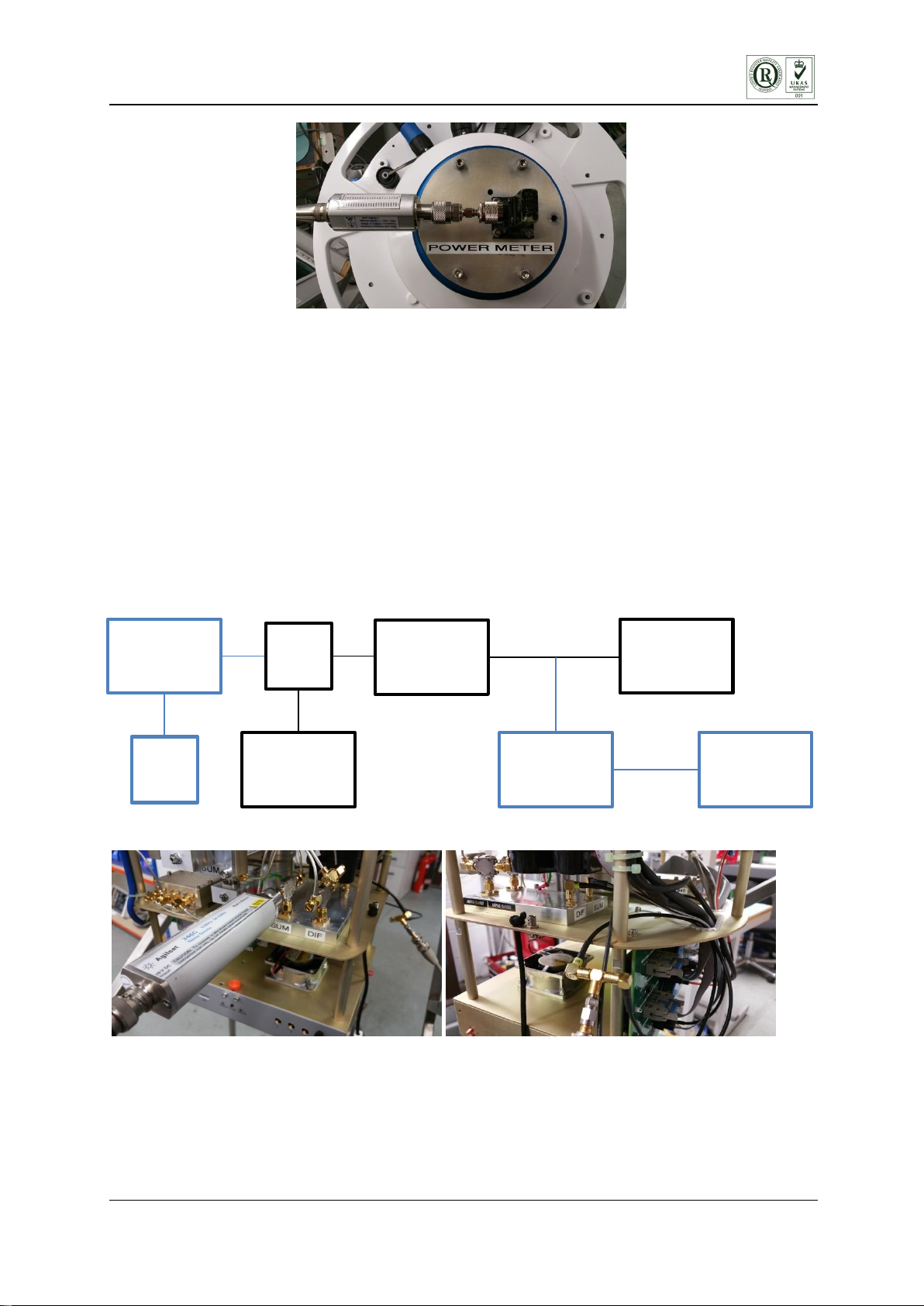

Test setup block diagrams –Black boxes are part of the Artemis build, Blue boxes

are attached test equipment.