B. Electrode Contact Test

-The instrument will begin the electrode contact test prior to taking any measurements and will only test the electrodes

required to complete the next phase of measurement.

-Electrode Test Pass:If all electrodes pass, the instrument will begin survey measurements automatically.

-Electrode Test Fail:If the electrode test fails, the instrument will wait for further user instruction. The ‘Progress’ view will

display a message, “Electrode test FAIL (OK: XX, Bad: XX, Fail: XX)”, indicating how many electrodes were good, bad, or

failed based on the threshold settings.

-Push emergency stop button prior to handling cables/electrodes.

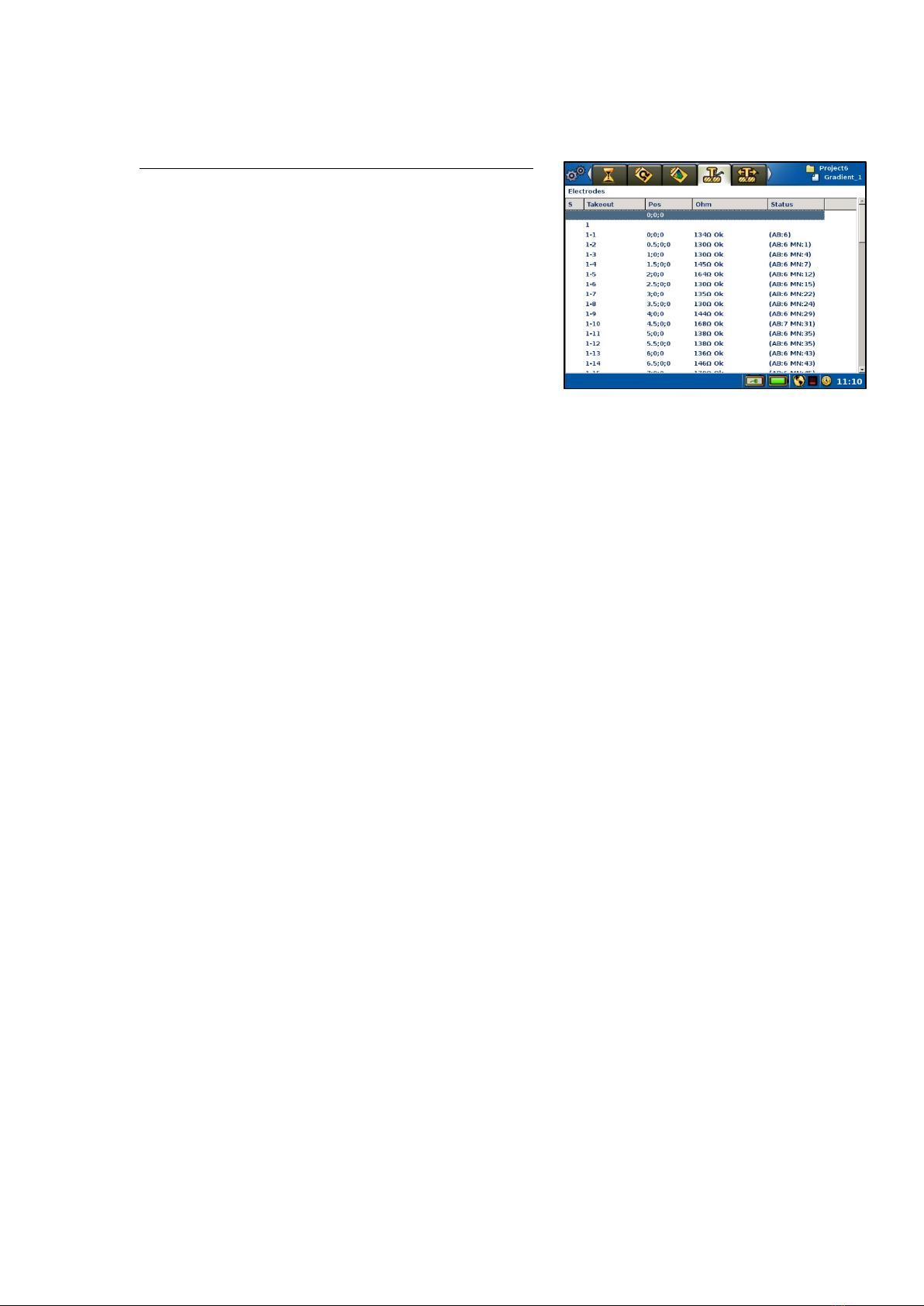

-Navigate to the ‘Electrode’ view. This tab displays a table detailing the

results of the electrode contact test.

-Pay attention to columns ‘S’ (special instructions given to a cable or

electrode), ‘Takeout’ (which indicates cable # - takeout #), and ‘Ohm’

(measured contact resistance and a corresponding notification).

-Identify all electrodes that have a ‘Bad’, ‘Fail’, or ‘No Contact’

notification in the ‘Ohm’ column (consider increasing the threshold if

most electrodes are ‘Bad’, with similar contact resistance values).

-Locate the problem electrodes on the survey line.

-First, check jumper wires are firmly connected to the electrode and

take-out. Next ensure that electrodes are well grounded (hammer

deeper, reposition slightly, add water, double-up electrodes etc.).

-Release the stop button and restart measurement (either from

Progress tab or by pressing the Play/Pause button). This will automatically retest all the ‘Bad’, ‘Fail’, or ‘No Contact’

electrodes. This will NOT retest electrodes that have already passed.

-After retesting, the instrument will either begin the survey or produce another failed message.

-In case of another fail, repeat the process of locating poor electrodes and attempting to improve their grounding.

-Retest the electrodes after each improvement. Repeat the process, until the electrode contact test passes.

-Note In some cases, it may be necessary to exclude or force the use of individual electrodes which can be done manually

or by choosing an automatic option such as excluding all ‘Bad’ electrodes from the popup menu (accessed by pressing the

OPT key). It is also possible to exclude a whole cable through the pop-up menu. Any excluded electrodes will have an “X”

next to them in first column; those which are forced to be used despite failing the electrode test will have a “U” adjacent to

them.

-When deciding to exclude electrodes, use the Status column to see the impact it will have on the final dataset; the “AB”

count is how many times that electrode will be used for current injection, the “MN” count is how many times it will measure

voltage.

C. Measurement Progress

-Navigate to the ‘Resistivity Results’ view to monitor real-time measurements.

-The table displays channel number, electrode pairings used for measurement (cable#- electrode#), measured quantity

(voltage or current), normalized standard deviation (variation coefficient), resistance, apparent resistivity and, if applicable,

chargeability (IP) from the first-time window (as this is the one at risk of spiking from the current switch-off). The bottom

row reports the final transmitter output voltage and current.

-Watch for high standard deviations, excessive negative IP values and/or error messages that may appear during survey.

-The measurement progress is shown on the left side of the status bar (described by how many measurements are

complete out of the total number of station measurements). Compare this with the “Cables in use” notation on the

‘Progress’ tab, which will tell you if any of the 4 cables are no longer needed.

-When measuring is complete, a ‘Measuring Done’ message will appear in both the ‘Progress’ view and the status bar.

FILE MANAGEMENT

-The most effective way to download data is through the PC companion software ABEM Terrameter LS Toolbox, via ethernet

or Wi-Fi connection. Refer to the ABEM Terrameter LS Toolbox user manual for more information.

-To download data using a USB storage device, insert the device into the USB port on the end panel of the instrument and

wait a few seconds for USB device to be recognized and read.

-Note You cannot download data (projects or tasks) that are open to USB. The currently active project and task is shown in

the upper-right corner of the screen. To change active projects/tasks, open a different pre-existing project/task or create a

new project/task.

-USB Project Download: Navigate to the ‘Project List’ view.

oHighlight the project and press the OPT key. A smaller pop-out menu screen will appear. Select “Export Project” (if

grayed out, ensure the project is inactive and the USB device is in the USB port).

oSelect < Yes > when prompted to export the project to the USB. Note The project database file is required for

opening data in ABEM Terrameter LS Toolbox and undertaking quality assurance procedures and filtering.

-USB Task Download:Navigate to the ‘Project List’ view and open the project containing the task(s). Ensure the task is

inactive.

oHighlight the task and press the OPT key. Select the file format preference, then select < Yes > to export.

oWhen data are downloaded, take out the USB memory device from the USB port.