Grain Filling

Grain filling is optional, and mostly depends on the wood your guitar is made from and

whether you are aiming for a flat finish.

If your guitar is made from an open grain timber such as Oak or Mahogany, the open pores

of the timber will prevent a flat finish unless filled.

Basswood for the most part is optional. In most cases it’s advisable to grain fill but if

painting a solid color (which we are in this case) you can get by using a primer which will

level and seal the surface.

If you are staining, depending on the product you are using, you can grain fill either before

or after. In most cases I’ve found grain filling first results in a more even application, and a

better result.

There are a number of different grain fillers available, including solvent, water and oil based

options, along with pre-tinted options. Oil based grain fillers penetrate deeper into the wood,

but water is obviously easier to work with with regard to drying times and clean up.

Using a tinted grain filler is a great option if you want to accentuate the grain pattern of the

guitar, as the excess will be removed when sanding but the filler used to pack the pores of

the wood will remain in place, emphasizing the grain pattern of the wood under a

transparent finish.

Below are the steps required for applying grain filler:

1. Mix up enough product to grain fill the entire guitar. Follow the recommendations for

the product you are using in terms of application, cleanup and safety, then mix your

grain fill into a workable paste in a spare container.

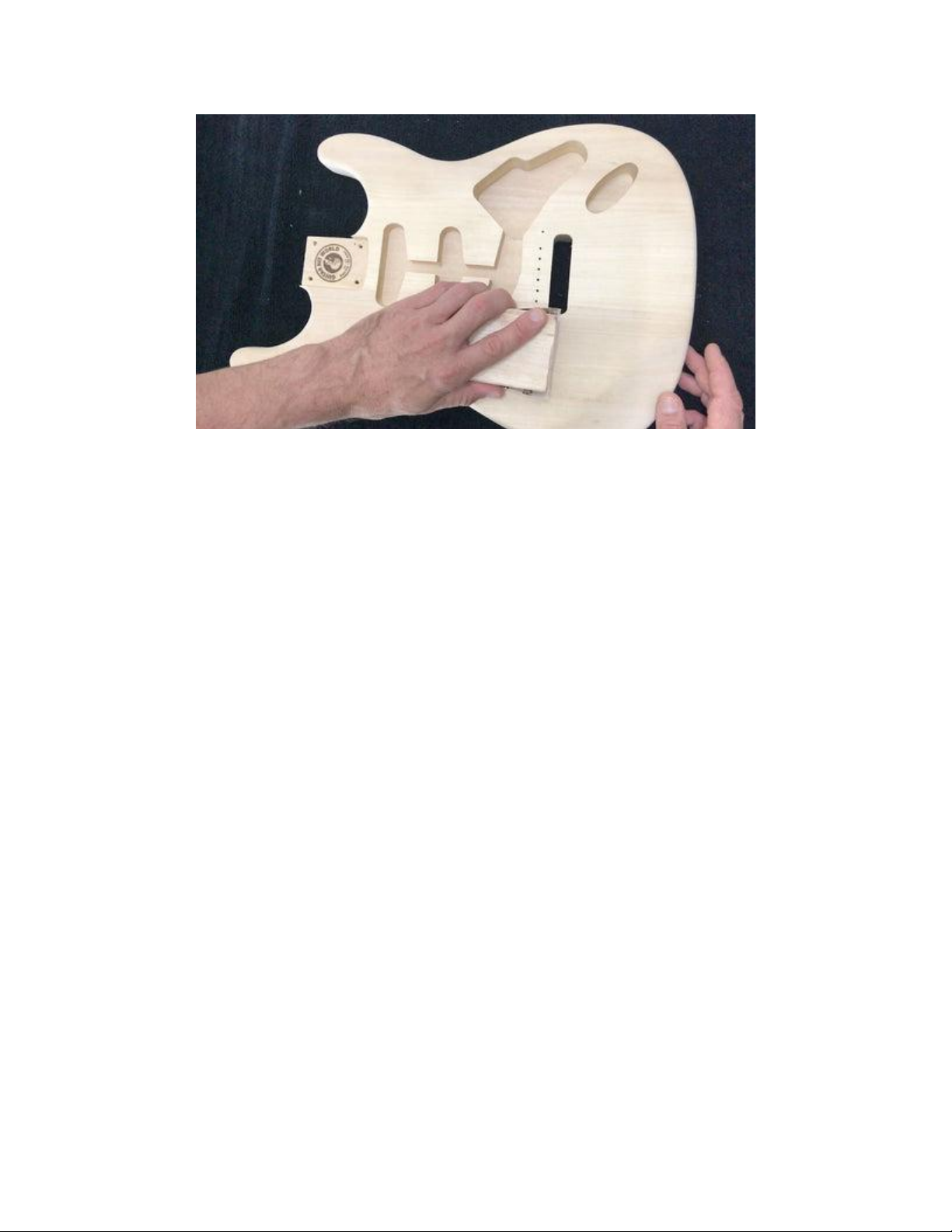

2. Apply to the guitar using a clean rag, working in line with the grains pattern of the

wood. Next, work across the grain really pushing the grain fill into the wood, making

several passes.

3. Once finished applying, leave the guitar for ten minutes and then wipe away any

excess using a clean damp rag.

4. Once dry, sand back to the surface level of the guitar, working through the grades of

sandpaper from 120 grit to 240. Sand sufficiently to remove the excess grain fill but

not enough to dig into the wood and create more open pores.

5. Inspect the surface of the guitar and repeat the process if required.