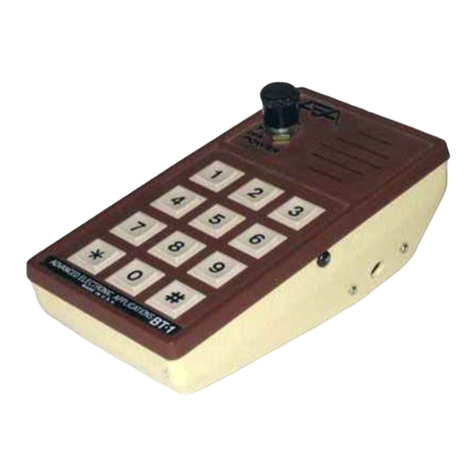

H.E. Anderson Ratio:Guard Advanced User manual

Ratio:Guard®

Advanced EC & pH Monitor

Designed for stand alone monitoring or for automatic control of EC & pH when

used with the Anderson J+ Advanced In ector controller

GETTING TECHNICAL ASSISTANCE

The H.E. Anderson Company is dedicated to assisting our customers with installation and use of our

products. Our technical staff are available each weekday from 8:30am to 4:30pm central time. You may

call us toll free at 1-800-331-96 0 from anywhere in the U.S.A.. and Canada. If no one is available, we

will promptly return your call.

Before you call, we suggest that you review this manual. You may find the answer to your question here.

But even if you do not, reviewing the manual will help us to help you.

There is some information you should have available when you call. You should know the software

version and serial number of your control unit. Also, you should note the number of pumpers of each type,

and their model numbers. We may not need all this information, but having it available at the start can

some times save a lot of time and trouble for you. You may record the information on the information page

below for convenient reference.

If you need an additional owners manual for any H.E. Anderson Company product, please visit our

website at http://heanderson.com/manuals.php

03/18/21

UNPACKING

Please open and inspect your

package upon receipt. Your

package was packed with great

care and all the necessary

packing materials to arrive to you

undamaged. If you do find an

item that is broken or damaged,

you must contact the delivering

carrier to report the claim.

ATTENTION!

Your pH electrodes must

be calibrated before use.

Ratio:Guard® Advanced - Information Summary

MODEL NO. _____________ SERIAL NO. ____________ SOFTWARE VER.______________

This unit was ordered with the following sensors & accessories:

Anderson Digital EC Transmitter W/Cable

Mounting Tee for above

Anderson Digital Temperature Transmitter W/Cable

Mounting Tee for above

4- 0 ma Toroidal EC Transmitter W/Cable

Mounting Tee for above

Anderson pH Electrode w/Digital signal converter Qty. _____

& Cable

Mounting Tee for above Qty. _____

2

Installation

When the monitor is supplied as part of a pre-assembled system the monitor will often be totally or at least

partially wired and configured as received. If this unit is added to a new or existing system this manual will

guide you through the installation and wiring process.

Summary of installation steps:

1. Decide where to place all system components. Consult component specific HEA manuals for individual

components (Monitor Enclosure, Sensor Tees).

. Install and leak check all plumbing including the manifold supply, water meter, in ection point fittings

and blend tank.

3. Mount controller and make connections between the controller and all sensors ordered with your

system. This monitor is designed to connect to the following sensors:

Anderson digital EC transmitter with associated temperature transmitter or A toroidal EC sensor with 4-

20 ma current loop interface

Any combination of 1 or 2 pH transmitters consisting of any combination of Anderson pH electrodes

with digital converters for digital input or other sourced pH transmitters with 4-20 ma analog interface

4. Power up the monitor

5. Refer to Ratio:Guard® EP- Advanced pH & EC Monitor Set-Up instructions to configure the

monitor using the front panel keypad.

Do all wiring before connecting power. Use a surge suppressor on the incoming AC power line. Plug in the

power cord and watch the LCD display. If it does not come on, unplug the power and check the wiring.

Mounting

Ensure the installation location has all the following:

●Allow easy access to front panel

●Must have access to 120 VAC power outlet.R

●Close proximity to other in ector components.

●Protect from direct spray

Mount the controller using the 4 metal tabs on the back of the controller enclosure.

Installing the Sensors

●The sensor tees should be installed in a bypass with isolation valves so they can be removed

without shutting off the water flow. All the sensors may be installed in a single bypass loop.

●The EC electrode and temperature sensor supply high level digital signals to the monitor. This

greatly reduces cable related problems and increases accuracy. Sensors come with fifteen feet of

cable. Cables may be extended if necessary, with no effect on performance.

●The monitor, sensors, and signal conditioners should be mounted out of direct sunlight and

protected from direct spray. The monitor enclosure and front panel are not UV resistant.

●The recommended installation is shown in Figure 1. It can be varied to suit your needs, but

remember the following:

●The bypass for the tees should always be below the main water line, especially if a pH electrode

is installed in the bypass.

●You must have some restriction in the main water line to insure water flow past the electrode.

●It is recommended that Anderson EC sensors be installed horizontally and pH electrodes be

installed vertically.

●A sample valve (a hose bib will do) installed as shown in Figure 1. is a great convenience. It can

also make electrode removal much easier by opening it to allow air to enter the line when

removing the electrode.

3

Connecting the Sensors

Complete the following steps to connect the control box to the required components:

1) Make sure the monitor is NOT connected to electricity.

2) Open the enclosure by releasing the two latches on the right side of the enclosure.

3) The sensor cables may already be connected to the terminal blodks. If they are not or more

sensors are being added, feed the cables through the most convenient strain relief bushing on

the bottom of the box, then connect the wires up to the proper terminal block.

➔For Anderson digital sensors (1-4), match the ‘1’, ‘2’ and ‘3’ on the sensor cable to the

corresponding numbers on the terminal block.

1 – Signal Ground

2 – Signal Input

3 – + 5 VDC supply

4

Sample valve

for taking water

samples.

Valve provides restriction to

main water line to force flow

through sensor manifold.

Ad ust for moderate

flow through

the manifold.

Sensor Bypass Loop

Showing proper sensor positions

IMPORTANT: Be certain

both isolation valves are

open during normal

operation. Otherwise

the unit will not

operate properly.

Isolation

Valve

Anderson pH Electrode

(Mount Vertically)

Sample valve

for taking water

samples.

pH Electrode

cable connects to

Anderson signal

converter

Anderson pH Electrode

(Mount Vertically)

Anderson supplied

toroidal EC sensor

(Mount Vertically)

Isolation

Valve

Anderson digital

EC sensor

(Mount horizontally)

Anderson temperature

sensor (Mount horizontally)

Illustration 1

➔For 4- 0 ma current loop transmitters there are two possibilities:

●USING AN ACTIVE TRANSMITTER WITH ITS OWN INTERNAL DC POWER SOURCE

OR USING A SEPARATE DC POWER SOURCE:

•Connect the – side of the transmitter to terminal 2 of the terminal block.

•Connect the – (ground) side of the transmitter to terminal 1 of the terminal block.

●USING THE MONITOR’S INTERNAL 12 VDC SUPPLY AS THE POWER SOURCE:

•Connect the + side of the transmitter to terminal 3 of the terminal block.

•Connect the – side of the transmitter to terminal 2 of the terminal block.

•The sensor cables may already be connected to the terminal blodks. If they are not or

more sensors are being added, feed the cables through the most convenient strain relief

bushing on the bottom of the box, then connect the wires up to the proper terminal

block. For Anderson digital sensors (1-4), match the ‘1’, ‘2’ and ‘3’ on the sensor cable to

the corresponding numbers on the terminal block.

1 – Signal Ground

2 – Signal Input

3 – +5 VDC supply

Powering Up The Unit

Plug the controller A surge suppressor/uninterrupted power supply should be used to power the controller.

When power is applied to the unit, the display will flash and then show:

Anderson Injectors

Ratio:Guard(tm)

Version Number

Version Date

for a short time as it initializes. It will then display pH, EC, and temperature readings, depending on what

sensors are connected.

5

Terminal Connections:

1. Anderson digital (contacting) EC electrode

2. Anderson digital temperature probe (used for EC temperature correction)

3. pH electrode #1 using Anderson digital signal converter

4. pH electrode #2 using Anderson digital signal converter

5. 4-20 ma analog input for a toroidal EC transmitter

6. 4-20 ma input for analog pH transmitter #1

7. 4-20 ma input for analog pH transmitter #2

8. RS-485 communications connection to J+ Advanced in ector controller.

9. The auxiliary inputs AUX1, AUX2, and AUX3 are not currently implemented.

8 42 3 5 91 76

Configuring and Setting the Monitor

You must configure the monitor to tell it what sensors are connected to it. EC and

temperature sensors come calibrated from the factory However, the pH transmitters

must be calibrated to the electrodes to display accurate readings. Refer to the

Ratio:Guard® Advanced pH & EC Monitor Set-Up instructions for complete information

on configuration and pH electrode calibration.

Repair

Before opening the enclosure and doing anything inside shut off ac power to the

unit.

The fuse is located on the DIN rail next to the power supply, inside the plastic fuse holder.

Replace with the same size and type.

Fuse Replacement

Other repairs are made by replacing complete circuit board assemblies. This should be done only by an

authorized repair person or under the direction of our technical staff.

Factory Service

Should you require service for your Ratio:Guard® Advanced monitor, the H.E. Anderson Co. offers

several flexible factory service options. Call our number listed in the front of this manual for complete

information. If you need to return any parts for service or replacement, our shipping address is:

H.E. Anderson Company

0 5 Anderson Drive

Muskogee, Oklahoma 74403

USA

Please enclose a note detailing the problems and the type of service you need. Include the name of a

contact person, phone number, and the billing name and address. Any return for warranty, or credit, must

have an RMA number. Contact H.E. Anderson for this number before returning.

6

Ratio:Guard™ EP-2 Advanced pH & EC Monitor Set-Up

You can use the ▼ and ▲ keys to navigate the top level menus in forward or reverse order. After a 10 seconds with

no key pressed the display will return to the base display although that delay may be extended in some instances.

ressing the Cancel/Exit key will return to the base display immediately.

A top level menu item with 'Q' at the margins allows pressing Enter to enter/change a value or perform the displayed

function. ressing Cancel/Exit will exit the screen will return to the upper level or to the base display.

All numeric entries are right justified as they are entered. Decimal places are fixed, and when entering values with

decimal positions, trailing zeros must be entered.

The normal (base) display

Line 1

shows the pH value and

source.

(electrode #1, #2, or Avg.).

Line 3 shows the EC and

temperature (°F) if a digital

temperature probe is

present.

Lines 2 & 4 will show pH &

EC alarms.

Lines 2 & 4 may show

other Info depending on

configuration and other

factors.

See Configuration

Sub-menu, age 3.

You should have the

Version # and date

available when calling

factory support.

ress Enter to

advance to the

temperature format

selection screen.

Choose between

Fahrenheit or Celsius

display.

Normal base) display and top level menu rotation

ress Enter to advance

to the high alarm

setpoint entry screen.

ress Enter to advance

to the high alarm

setpoint entry screen.

ress Enter to advance

to the low alarm

setpoint entry screen.

ress Enter to advance

to the low alarm

setpoint entry screen.

Your monitor must

be calibrated to the

electrode before

using therwise the

readings will not be

correct!

See pH Calibration

Sequence, age 2

07/01/19

PH Calibration Sequence

The pH Calibration applies to Anderson pH electrodes or pH electrodes using the Anderson /N 11552 pH Converter Module

connected to a pH digital input. Electrodes assigned to an analog input (4-20ma) may or may not require calibration to this

monitor. See instructions below right.

Read the separate Instructions for the /N 06916 pH Electrode Calibration Kit. before advancing to the pH calibration sequence.

You must have prepared solutions and have access to the electrode to calibrate.

N TE: Some sections of the kit instructions apply specifically to the -1 pH monitor and will not apply here. Ignore those specific

instructions and follow the procedure below.

Once you start through the calibration sequence for an electrode the Enter key to proceed through the sequence. You may abort

the sequence at any point before completion and no new calibration numbers will be recorded.

The sequence must be repeated for each of two possible electrode hook-ups.

The monitor will perform all its functions with either one, or two electrodes. If two electrodes are attached the pH display will

display “Avg.” to the right of the reading. If only one calibrated electrode is attached, the display will show either “#1” or “#2”.

The calibration process will go

through several measurement

iterations to determine if the

readings have stabilized.

The left number (line 3) is the

iteration #, and the right # is

second tics per iteration.

If an electrode has previously

been calibrated the display

will show two calibration

numbers designated 7: and

U:. They are determined by

the calibration routine. The

numbers are likely different

for each electrode and and

will change with each re-

calibration as an electrode

ages. You may be asked for

these numbers when

contacting customer service.

If an electrode has not been

calibrated it will be shown as

such. A pH input which has a

defective , or no electrode

attached will show as not

calibrated on this screen

An input which has not been

assigned to a digital or analog

input will be shown as such.

Unassigned inputs cannot be

calibrated..

ress Enter to advance to

the next step.

R

Other error displays you

may encounter will be self

explanatory.

lace the electrode in the

pH 7 solution and ress

Enter to continue..

Enter

Error displays

Select the electrode to calibrate

and press Enter to advance to

the next step. (Displayed only if

both pH inputs are assigned)

A calibration error at pH

7 or 4 indicates the

electrode is too old or

has otherwise failed and

will not calibrate. The

calibration will abort, but

the monitor will continue

operation with the

previous calibration

numbers.

age 2

Enter

Enter Enter

Example 2

Example 1

Clearing the Analog

Calibration Settings:

With power ON to the unit,

open up the door to the

enclosure.

Locate the small reset

push-button on the

processor board.

With the door open, on the

front panel press and hold

the '7' Key (for Input #1) or

the '9' key (for Input #2),

and while holding the key,

press the reset button to

restart the processor. This

will clear the settings and it

will revert to the default

settings. A message

showing the values have

been cleared will display

for 5 seconds.

NOTE: This procedure

may be easier with two

prople.

Using a Calibrated 4-20ma Analog Input

If you are using this monitor with a separately calibrated pH

transmitter with 4ma = pH 0 and 20ma = pH 14 you do not need to

calibrate the analog input on the E -2 monitor. Instead you should

use the default (uncalibrated) settings for that input.

If the EP 1 input has already been calibrated, the settings must be

cleared before re calibrating See below.

Using an Uncalibrated, Blind Transmitter, or a

Transmitter Calibrated to a Different pH Range.

In these cases you may also calibrate an analog input just as you

would a digital input. (using pH 7 and pH 4 solutions)

Note: Any adjustment you make to the pH transmitter will affect the

readings on the monitor. You should re-calibrate the monitor to the

transmitter after any adjustments.

Sensor Input Configuration

The Ratio:Guard monitor comes congured for one or two pH sensors and one EC sensor. Two options

are oered for each input; Digital Pulse input legacy Anderson) or 4-20ma Analog. It is fully

compatible with any Anderson sensors you may already have.

A digital pH input provides greater resolution and accuracy but requires our P/N 11627 Signal

Converter. If you already have one this should be your setting.

The digital EC input works directly only with an Anderson digital EC electrode and provides greater

resolution than a 4-20ma analog input. But for greatest reliability the best choice is a contactless

toroidal EC sensor. It is more expensive, but provides superior reliability and much lower

maintenance.

With an analog input you must also enter the EC range limit. This is the 20ma calibration point of

your EC sensor. Allowable values are 2.0-10.0 milliSeimens mS). The lower this value is, the ner the

resolution of the EC reading.

Cancel

The default setting is No

Input Assigned. Otherwise

the cursor will show the

current setting.

Enter

The EC Range Limit is displayed only if the

4-20ma analog input is selected.

This is the full scale (20ma) EC value and

depends on how the EC sensor is calibrated.

Set Input

Cancel

Set Input

Enter

4-20ma ?

No

Yes

4-20ma ?

Cancel

Enter

Enter

No

Yes

Enter

Enter

Cancel

Enter Set Input

Enter

Set Input

Cancel

Enter

Enter

Enter

Enter

age 3

Table of contents

Popular Measuring Instrument manuals by other brands

Medical International Research

Medical International Research Spirolab III user manual

SevenStar

SevenStar CS200-J user manual

Spectrum Technologies

Spectrum Technologies LIGHTSCOUT 3415A product manual

HydroAir

HydroAir P-38 Series Operation manual

Spycentre Security

Spycentre Security 1812 manual

Allen-Bradley

Allen-Bradley 1756-CFM user manual