Teesing Aeroqual Dust Sentry Pro User manual

Table of Contents

User Guide Revision History ......................................................................................................... 4

1. Description........................................................................................................................... 5

1.1 Optical Particle Counter.......................................................................................................... 6

1.1.1 Electrical connections .....................................................................................................6

1.1.2 Data Outputs................................................................................................................... 6

1.1.3. Inlet Heater ..................................................................................................................... 7

1.1.4. Filters............................................................................................................................... 7

1.2. Pump Module.......................................................................................................................... 7

1.3. Control Module....................................................................................................................... 8

1.4. Power Module......................................................................................................................... 9

1.5. Analogue Output Module (Optional)......................................................................................9

1.6. Auxiliary Module (Optional)....................................................................................................9

1.6.1. Wiring of Auxiliary Module ...........................................................................................11

1.7. Gatetel GT-HE910_G Cellular Terminal (Optional) ...............................................................11

1.7.1. Specifications ................................................................................................................12

1.8. Electrical Connections...........................................................................................................12

1.9. Alarm Relay ...........................................................................................................................13

2. Assembly and Installation ................................................................................................... 14

2.1. Assembly of heated inlet ......................................................................................................14

2.2. Connect Mains Power ...........................................................................................................15

3. Dust Sentry Pro Operation and Software ............................................................................ 16

3.1. Getting Started...................................................................................................................... 16

3.2. System Checks.......................................................................................................................18

3.3. Modem configuration ...........................................................................................................18

3.3.1. Further information about IP address solutions using GPRS Systems..........................20

3.3.2. Email Message ..............................................................................................................20

3.3.3. SMS Message ................................................................................................................21

3.4. Software Description Summary ............................................................................................21

3.4.1. File.................................................................................................................................21

3.4.2. Setup ............................................................................................................................. 23

3.4.3. Data...............................................................................................................................23

3.4.4. Tools.............................................................................................................................. 24

3.4.5. Calibration.....................................................................................................................24

3.4.6. Diagnostics (Available in Engineer Mode) .................................................................... 24

4. Maintenance ...................................................................................................................... 26

4.1. Maintenance Schedule .........................................................................................................26

4.2. Maintenance Procedures...................................................................................................... 26

4.2.1. Sample Flow Check and Adjustment.............................................................................26

4.2.2. Sheath Flow Check ........................................................................................................27

4.2.3. Leak Check.....................................................................................................................27

4.2.4. Manual Zero Air Check..................................................................................................28

WWW.DUSTSENTRY.NL | +31 70 413 70 50

4.2.5. Filter Changes................................................................................................................ 28

4.2.6. Inlet Cleaning ................................................................................................................28

4.2.7. Pump Module Removal.................................................................................................28

5. Calibration ......................................................................................................................... 29

6. Troubleshooting ................................................................................................................. 30

7. Specifications ..................................................................................................................... 32

8. Schematic Diagrams ........................................................................................................... 33

8.1. Pneumatics............................................................................................................................33

8.2. Electrical................................................................................................................................ 33

8.3. Communication..................................................................................................................... 34

9. Third Party Sensors............................................................................................................. 35

9.1. Sensirion T/RH Sensor SHT75................................................................................................35

9.2. Gill WindSonic ....................................................................................................................... 35

9.3. Met One 034B .......................................................................................................................35

9.4. Met One MSO .......................................................................................................................36

9.5. Vaisala Weather Transmitter WXT520 .................................................................................37

9.6. Cirrus MK:427 .......................................................................................................................38

10. Mounting and Site Positioning Guidelines ........................................................................... 39

10.1. Mounting...............................................................................................................................39

10.2. Inlet height............................................................................................................................ 39

10.3. Measurement Interference...................................................................................................40

10.4. Safety ....................................................................................................................................40

11. Orbit DATA......................................................................................................................... 41

11.2. Specifications ........................................................................................................................41

11.3. Configuring the Orbit Modem...............................................................................................41

11.4. Using the Orbit DATA Website.............................................................................................. 42

11.4.1. Using the Graphs...........................................................................................................43

11.4.2. Setting Alarms ...............................................................................................................44

11.4.3. Downloading Data......................................................................................................... 44

12. Appendix............................................................................................................................ 45

12.2. Warranty ...............................................................................................................................45

12.3. Technical Support .................................................................................................................45

12.4. Declarations ..........................................................................................................................45

WWW.DUSTSENTRY.NL | +31 70 413 70 50

User Guide Revision History

Document Number: MRK-D-0021

Product Version: 1.2

Document Version: 1

Date released: April 2014

Description: User Guide for Dust Sentry Pro

This user guide is a newly created document for the use of the Aeroqual Dust Sentry Pro.

Date

Revision number

Description of change

Affected pages

April 2014

V1

Initial draft

All

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.Description

Aeroqual’s Dust Sentry Pro is a user friendly instrument designed to provide continuous particulate

measurement of PM10, PM2.5, PM1, and TSP. It uses an optical particle counter to count and classify

particulate matter according to size. The instrument then converts the size distribution into a mass

measurement.

The instrument includes an integrated internal data logger, alarm relay outputs and a SD card as

standard. There are also numerous additional options available, including, wireless communications,

SMS and email notifications, weather sensors and GPS. The instrument is packaged in a robust,

lockable enclosure and is light enough for one person site installations. The ease of installation, as

well as the extensive range of possible add-ons, enables the unit to be used in a wide range of

applications.

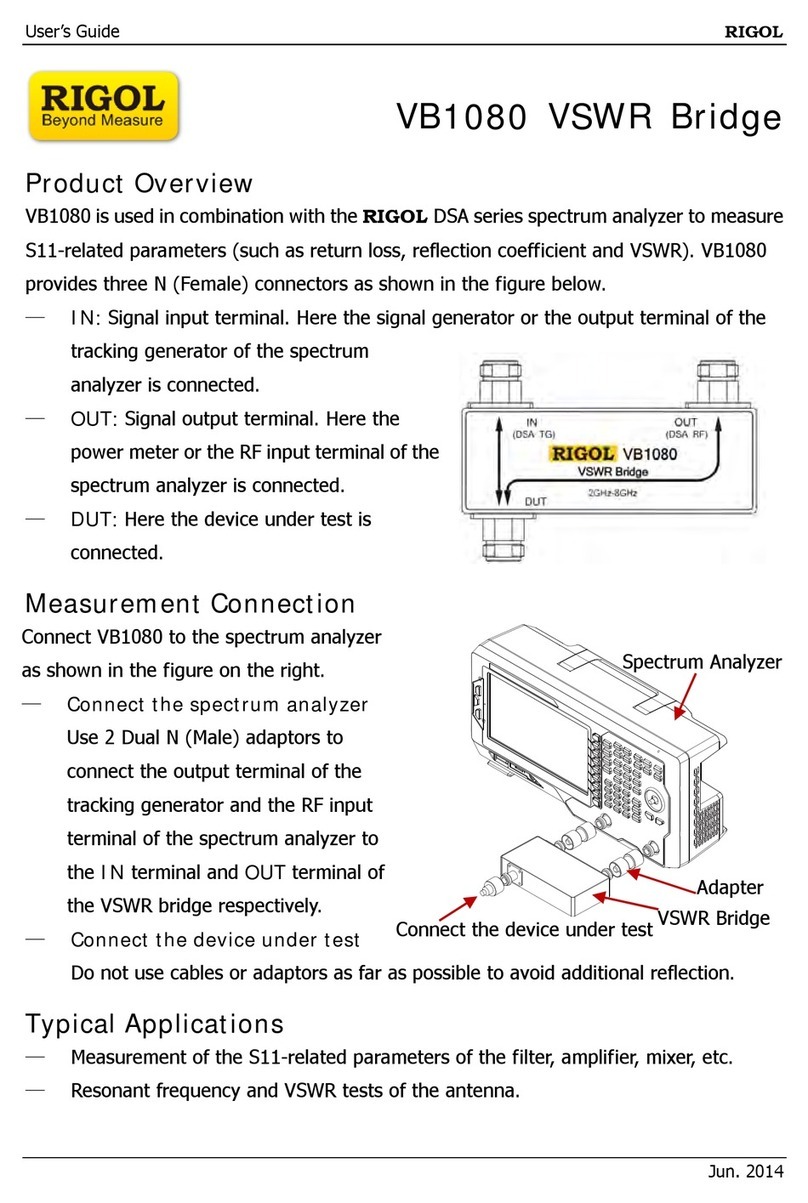

* Shows location of optional components if installed

Note: 12 VDC Power Supply mounted externally at base The

key components of the Dust Sentry Pro are described below.

Modem* (Optional)

Auxiliary Module*

(Optional)

Modem Antenna*

(Optional)

Power to Sensor

Relay

RS232 to USB

Adapter

Alarm Relay

Optical Particle

Counter

Control Module

Sample air filter (DQ)

Sheath air filter (BQ)

Analogue

Output Module*

(Optional)

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.1 Optical Particle Counter

Aeroqual uses an OEM optical particle counter from Met One

Instruments. The particle counter uses scattered light to

measure and count particles. Light from a laser diode is

collimated to illuminate the aerosol sample flow. When a

particle is present it scatters the incident laser light which is

detected using a 60osolid angle elliptical mirror at right angles

to the laser beam. The amount of scattered light is converted

to a voltage pulse and the amplitude of the pulse is calibrated

to a particle diameter. The particles are thus assigned on the

basis of size to one of eight channels.

1.1.1 Electrical connections

The connections to the optical particle counter are at the bottom of the unit. There is also a LED which

turns red if there is a fault condition (see Troubleshooting section). The optical unit also requires an

earth wire to be connected between the housing and the 0VDC line on the power bus. Please check

that this is fitted if the unit has been replaced.

1.1.2 Data Outputs

The Dust Sentry Pro is configured to display and log particle mass by default. However, there is

also an option to configure the instrument to record particle counts. These can be chosen via the

configuration option in the PC software. Refer to Section 3.1 for more information.

Not used

RS232 serial

LED

Green = Normal

Red = Fault

12 VDC in

Not used

Air out

Safety: This sensor is considered a Class I laser product. Class I laser products are not

considered to be hazardous. There are no user serviceable parts inside the cover of

the sensor. The device contains a laser operating at 670 nm which is visible to the eye

and can cause damage to the eye if directly exposed. Only trained service personnel

should attempt servicing or repair of the sensor.

WWW.DUSTSENTRY.NL | +31 70 413 70 50

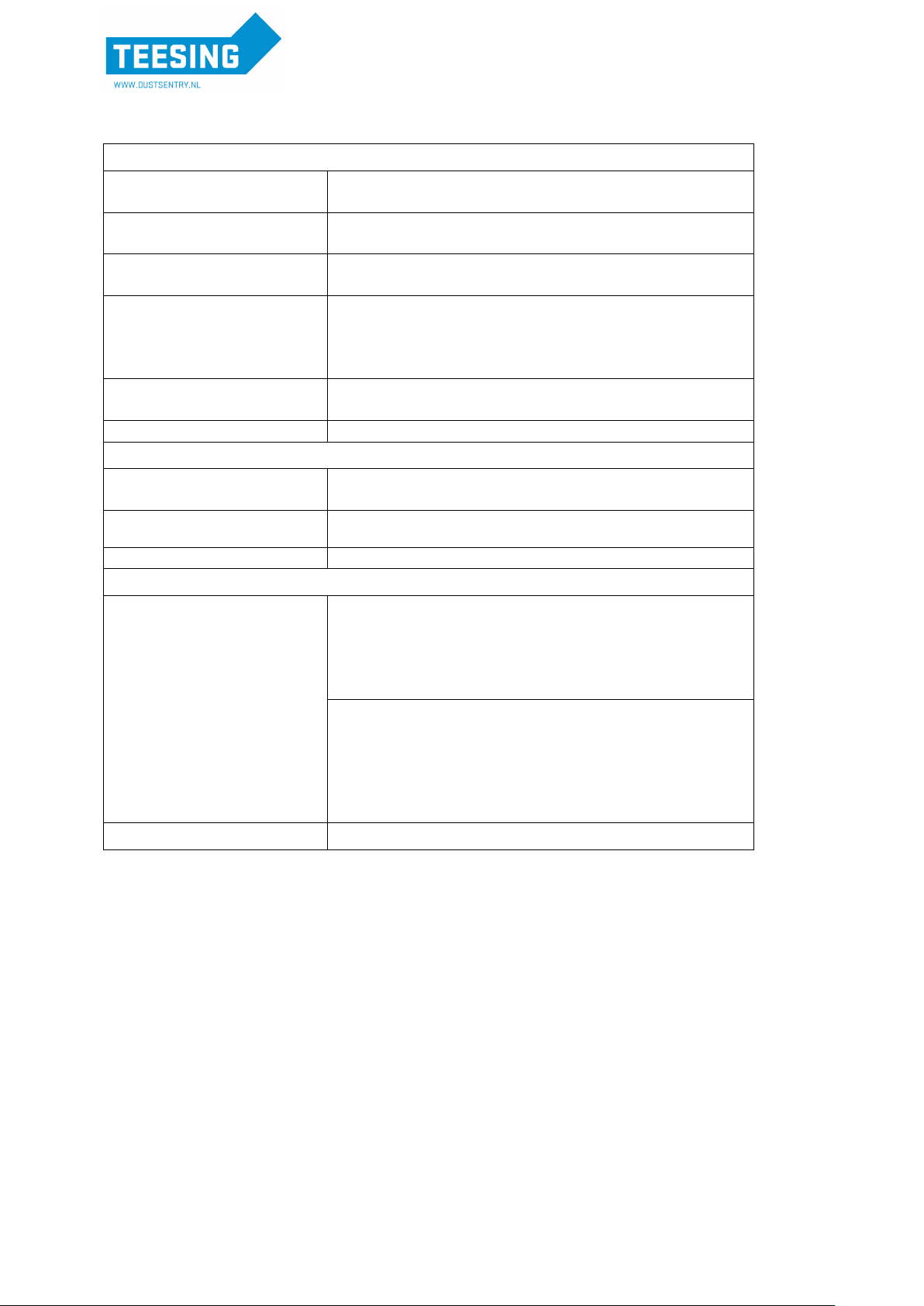

Sensor name

Definition

Range

Units

Default configuration

PM1

Particle mass below 1 µm

200

µg/m3

PM2.5

Particle mass below 2.5 µm

2000

µg/m3

PM10

Particle mass below 10 µm

5000

µg/m3

TSP

Total suspended particle mass

5000

µg/m3

Optional configuration

8PC0.3

Number of particles with diameter larger than 0.3 µm

0-1000000

particles/L

8PC0.5

Number of particles with diameter larger than 0.5 µm

0-1000000

particles/L

8PC0.7

Number of particles with diameter larger than 0.7 µm

0-1000000

particles/L

8PC1.0

Number of particles with diameter larger than 1.0 µm

0-1000000

particles/L

8PC2.0

Number of particles with diameter larger than 2.0 µm

0-1000000

particles/L

8PC3.0

Number of particles with diameter larger than 3.0 µm

0-1000000

particles/L

8PC5.0

Number of particles with diameter larger than 5.0 µm

0-1000000

particles/L

8PC10

Number of particles with diameter larger than 10 µm

0-1000000

particles/L

1.1.3. Inlet Heater

The Dust Sentry Pro uses a 12 V heater on the sample inlet tube to reduce the humidity of sampled

air to prevent particle growth and fogging of the particle counter optics in high RH conditions. The

inlet should always be heated.

1.1.4. Filters

The Particle Counter engine requires two filters which are installed externally. They are designed to

provide protection to the pump and optical window. The BQ filter is the sheath air filter and the DQ

filter is the sample air filter.

1.2. Pump Module

The Pump Module contains the sampling pump and a microcontroller which calculates the particle

counts and mass. The pneumatic design is provided in Section 8.

Power on LED

RS485 bus cable

Termination dongle

Cable from particle counter

Inlet heater connector

12VDC power

connection to

Purge air line with

flow adjuster

Sample line

Exhaust air line with

flow adjuster

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.3. Control Module

The control module is the interface between the RS485 sensor bus and data communication links. It

contains a display, a SD data card which logs data, a RS232 serial connector for external

communication, a bus connector for internal communication with the sensor modules and a cable

connector for the Sensiron Humidity and Temperature sensor (if fitted).

The Dust Profiler is supplied with a RS232 to USB adapter fitted between the Control Module and an

external USB socket fitted at the base of the enclosure. This enables the user to perform a wide range

of functions over the USB connection, without needing to open the enclosure door, such as data

logging and various system checks using the supplied Aeroqual Dust Profiler PC software.

Note 1: The driver for the RS232 to USB adapter is in the USB stick which comes with the

instrument.

Note 2: The power to sensor and alarm relays are also attached to the control module base

plate.

Display

Front

6 way Alarm Relay

SD Card Slot

DB9 RS232

4 way T/RH

2 way Bus relay

activation

RJ45 RS485

Bus

2.1mm 12VDC relay

switched Power output

Top

Bottom

Off/On switch with LED.

Depress to power on (blue

LED on)

Controller 12VDC

power input

Programming Port

RS232

Firmware (V6.2+)

Programming Dip

Switch (position is

important)

Firmware (V6.2+)

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.4. Power Module

The Dust Sentry Pro internal power requires regulated 12 VDC to maintain a constant pump speed.

An external mains to 12VDC power supply (Meanwell HLG80-12A 60W 12V) is fitted on the outside

of the enclosure and this will allow connection to mains supply.

Note: If you wish to run the Dust Sentry Pro on solar power you will need to use a DC-DC

convertor in order to supply a regulated 12 VDC for the Dust Sentry Pro –refer to the

application notes on the website

1.5. Analogue Output Module (Optional)

The Dust Sentry has the option to integrate an ADAM 4021 Analogue Output Module into the system

to allow for the digital inputs of a chosen sensor to be converted to an analogue output. The analogue

output module receives the digital input via an RS485 interface and converts it to a 4-20mA and 2-

10V output. These outputs follow each other.

Outputs:

4mA (2V) = 0% of full scale value.

12mA (6V) = 50% of full scale value.

20mA (10V) = 100% of full scale value.

The module is easily configured via the Operations menu in the PC software and can convert to an

analogue output any chosen sensor already integrated in the Dust Sentry. The module uses the

logging period to calculate the reading, which is also set in the Operations menu. This differs from the

alarm relay, SMS and email which all use the averaged alarm period to calculate the reading. For

more information regarding the PC Software and setting up the analogue output module please refer

to Section 3.1.

1.6. Auxiliary Module (Optional)

The auxiliary module acts as an interface between third party sensors and the Dust Sentry Pro

communication bus. It is configured with different operating modes which can be selected by using

the dipswitches located on the side of the module. Aeroqual has integrated a number of third party

sensors and is able to supply the auxiliary module preconfigured for your sensors.

WWW.DUSTSENTRY.NL | +31 70 413 70 50

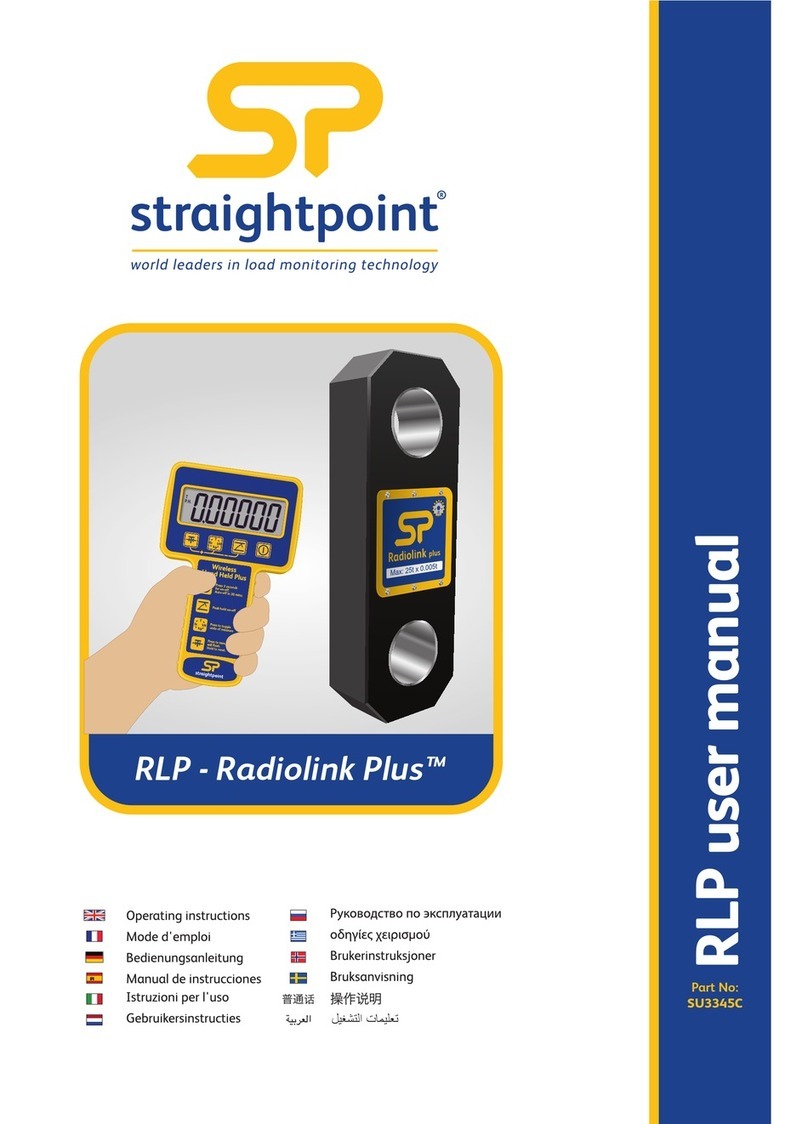

Firmware: AUX_MODULE_01.

Use for: Analogue inputs, Vaisala WXT520 weather, Gill Windsonic wind, Cirrus MK:427 noise.

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

OFF

OFF

Vaisala WXT520 with RS232 communication + AN1, AN2, Freq

OFF

ON

OFF

OFF

Vaisala WXT520 with RS232 communication + Cirrus MK427 Noise

ON

ON

OFF

OFF

Wind Sonic with RS232 communication + AN1, AN2, Freq

OFF

OFF

ON

OFF

Wind Sonic with RS232 communication + Cirrus MK427 Noise

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

Firmware: AUX_MODULE_02.

Use for: Analogue inputs, Met One MSO weather, Met One 034b wind, Cirrus MK:427 noise.

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

OFF

ON

ON

OFF

Met One MSO with RS232 communication + Cirrus MK427 Noise

ON

ON

ON

OFF

Met One MSO with RS232 communication + AN1, AN2, Freq

OFF

OFF

OFF

ON

Met One 034B analogue module + Cirrus MK427 Noise

Pin 12

Pin 1

Status LED

12VDC Power

Connectors

RJ45 Connectors

for RS485 bus

Programming Dip

Switch

Programming

Port

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.6.1. Wiring of Auxiliary Module

PIN 1: GND

PIN 2: 12V FUSED

PIN 3: RESERVED

PIN 4: RESERVED

PIN 5: RX

PIN 6: TX

PIN 7: 0-5V IN

PIN 8: 4-20mA IN

PIN 9: FREQ IN

PIN 10: AGND

PIN 11: METONE 034B PWR

PIN 12: TIMED RELAY

Example of wiring:

Wind Sonic

(Pin 1) GND,

SIGNAL GND

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Vaisala

(Pin 1) GND for

operating, data &

heating

(Pin 2) 12V for

operating & heating

(Pin 5) RX

(Pin 6) TX

Met One MSO

(Pin 1) GND,

SIGNAL,

COMMON, SHIELD

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Met One 034B

(Pin 1) GND

(Pin 12) VCC

(Pin7) WD

(Pin 9) WS

Cirrus MK:427

(Pin 1) GND,

ACTUATOR GND

(Pin 2) 12V, LOOP

IN

(Pin 8) LOOP OUT

(Pin 12)

ACTUATOR IN

A programming port is also exposed through the side of the module to allow custom programs to be

loaded into the module.

Note: Aeroqual can supply a standard programming tool for distributors to reprogram the

auxiliary module to the specified requirements.

1.7. Gatetel GT-HE910_G Cellular Terminal (Optional)

Aeroqual can provide a Gatetel GT-HE910_G Cellular Terminal with GPS for remote data access

over GSM, GPRS or SMS networks. Please read the Gatetel GT-HE910_G Cellular Terminal manual

for detailed instructions on configuration and use. Further information can be found at:

http://gatetel.com/products.php?product=22

WWW.DUSTSENTRY.NL | +31 70 413 70 50

1.7.1. Specifications

1.8. Electrical Connections

RS485 Bus

The two wire RS485 bus connections are made using 20 cm CAT5 cables between the sensor

modules. The last module on the bus also has a blue termination dongle fitted.

Note: If the Analogue Output Module is fitted the termination dongle is not required.

12 VDC Power Bus

All modules inside the Dust Profiler operate from the 12VDC power. The power is supplied by a daisy

chain of black and red cables. A relay is activated by the Control Module on/off button to allow the

sensor bus to be powered.

12 VDC Power in

12 DC power is connected into the instrument at the terminal connector strip (“chock bloc”).

Features

Incorporates Telit HE910-DG

module

The Telit module handles all GSM/UMTS GPS

processing with PYTHON script

Frequency bands

GSM: 850/900/1800/1900MHz

UMTS/HSPA+: 800/850/900/1700/1900/2100MHz

Power supply

Single supply voltage 6V DC to 55V DC

connector 4 pin micro-fit 3mm

ADC and GPIO inputs

Two outputs optocouplers open collector drive 100ma

Two inputs optocouplers, 0-55v

One ADC 10 bit , 0-55V

connector 6 pin micro-fit 3mm

Communication

Modem Full RS232, connector D-Type 9pin (DB-9)

Modem USB, Connector USB Type B High retention

Antennas

GSM/UMTS GPS via SMA connectors

Mechanical Description

Weight

180g (6.35oz)

0.4 lb

Dimensions(max) L x W x H

83mm x 64mm x 34mm 3.26inch x 2.51inch x 1.33inch

Case material

Aluminium

Environmental Requirements

Operating temperature range

-20°C to +55°C

-4°F to 131°F

Ambient temperature

The module is fully functional in all the temperature range

and it fully meets the ETSI specifications.

-30°C to +70°C

-22°F to 158°F

The module is fully functional (*) in all the temperature

range. Temperatures outside of the range –20°C to +55°C

(-4°F to 131°F) might slightly deviate from ETSI

specifications.

Humidity

5% - 85%

WWW.DUSTSENTRY.NL | +31 70 413 70 50

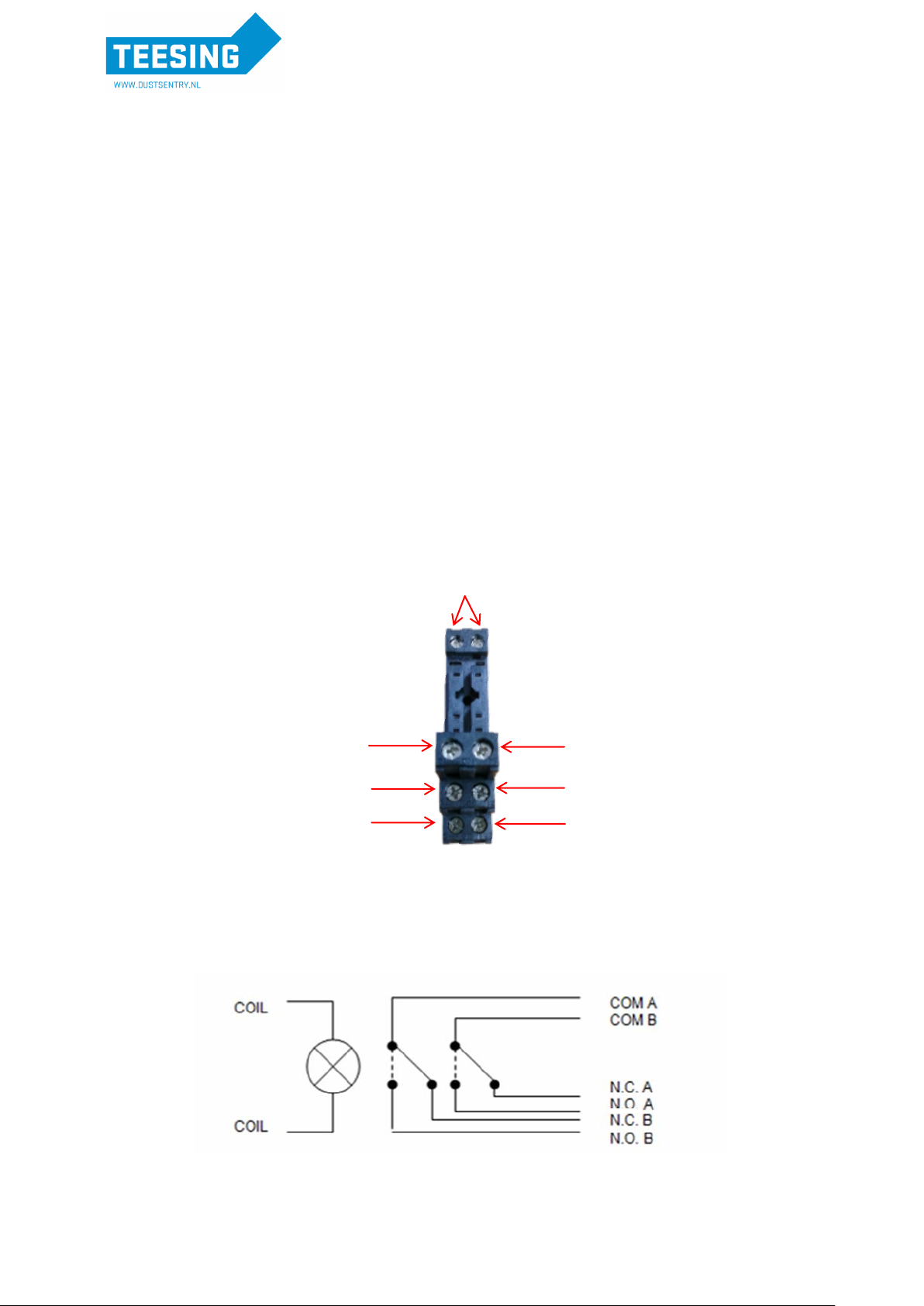

1.9. Alarm Relay

The Dust Profiler has a built in alarm relay function that is set up via the Operation Dialog in the PC

software (See Section 3.1.)

Relay Output: This is fitted as standard and is activated by “Enable Alarm Relay Output” tick box. If

the set point set in “Alarm trigger point” is exceeded the relay is activated. This can be used to

activate a siren or strobe or other peripheral devices. The relay remains activated until the measured

value drops below the reset point (expressed as a % of the trigger point). This is controlled via the

“Alarm reset point of trigger”. The “Alarm trigger point average period” determines the amount of time

that the concentration needs to be exceeding the trigger point before the relay is activated.

If “Active output on diagnostics” is selected the alarm will trigger upon sensor failure or sensor no

report. If not selected the alarms remain in the state they were in when the last valid reading was

logged.

The Alarm relay is energised by the Control Module in response to the alarm trigger point. The trigger

point is programmed into the Control Module via the Operation menu in the PC Software. The Alarm

Relay is a double pole; double throw type (see diagrams below). This allows the connection of two

different alarm signals –e.g. siren and strobe - that may have different power requirements.

The relay contacts rating: 2 x 5A @ 24VDC 220VAC.

Normally Open

A

Common

A

Normally Closed

A

Coil

Normally Open

B

Common

B

Normally Closed

B

Relay Internal Schematic

WWW.DUSTSENTRY.NL | +31 70 413 70 50

2.Assembly and Installation

2.1. Assembly of heated inlet

Parts List:

A. Inlet Tube/Heater including power cable

B. TSP Inlet

i. Connect parts A and B

ii. Open door of enclosure and remove protective tape from the optical engine

iii. Insert Inlet Tube Assembly through base mount and fix the three mounting screws

Note: Ensure the power cable is fed through the inlet hole when connecting

B

A

Tape

Mounting

Screws

WWW.DUSTSENTRY.NL | +31 70 413 70 50

iv. Connect power to Inlet Tube/Heaterinside the enclosure

2.2. Connect Mains Power

Locate the power connector terminal which is situated outside the enclosure at the bottom.

The power supply will already be wired to the connector however the cable to connect to

mains power needs to be wired.

Caution: The high voltage mains supply must be wired by a certified electrician

in compliance with local electrical regulations.

3. Reconnect into the connector

ensuring the plugs are fitted securely

and the nut gland tightened.

Plug

Nut gland

Connector

Terminal block

Neutral

(Blue)

Earth

(Yellow/Green)

Live

(Brown)

2. Feed the power cable through the nut gland

plugs and connector and wire the cable to the

terminal block according to the diagram.

Note: To remove the terminal block from inside the connector unclick it from the casing by

turning it slightly then pull out

1. Unscrew the nut

gland to loosen the

terminal block and pull

connector apart

Power cable

from heated inlet

WWW.DUSTSENTRY.NL | +31 70 413 70 50

3.Dust Profiler Operation and Software

3.1. Getting Started

Computer Requirements

CD-ROM Drive or internet connection for software download

RS232 serial port or USB –RS232 serial port converter and USB cable (included)

Windows OS version 2000 or later

Minimum 100 Mb of spare hard drive space

Recommended 512 Mb RAM or more

Recommended 1 GHz processor speed or faster

1. Once the Dust Profiler is assembled and power is connected install the SD card into the control

module.

2. Start the Dust Profiler by pushing the on/off switch on the control module (See Section 1.3 for

location of On/Off switch)

3. Connect the instrument using a computer via the USB cable to the outside of the enclosure

4. Install Aeroqual Dust Monitor software. This can also be downloaded from the Aeroqual

website at www.aeroqual.com

5. Launch the Aeroqual Dust Monitor PC software.

a. Select to log in as either:

i. User (default password = “password”)

ii. Engineer (default password = “aeroqual”)

Note 1: User has access to most day to day functions on the

instrument. Engineer has access to all functions, including

diagnostic parameters (Sensor Module Settings and Sensor

Diagnostic View).

6. Configure the Dust Profiler instrument:

a. Select Setup Communication Port

b. Select Serial Port RS232 and the relevant Com port. Press OK when complete.

Note 2: The settings should be as seen below:

Note 3: To connect via the modem select TCP/IP Socket and enter the network IP address and

port number. If the PC is behind a proxy server this information needs to be added as well.

WWW.DUSTSENTRY.NL | +31 70 413 70 50

7. Check configuration

a. Select Setup Configuration

b. Check the correct sensors in the Dust Profiler have been configured.

c. These should match the sensors on the invoice and the sensors list in the instrument

logbook.

d. Click Save and Close.

Note 1: The more sensors configured, the larger the data file will be. Therefore, the

download time will be longer if using a remote connection.

Note 2: The Dust Profiler needs to be restarted after a parameter change.

8. Set Dust Profiler Real Time Clock

a. Click on Tools Update Real Time Clock (this will synchronise the Dust Profiler

clock with the computer date/time)

9. Configure the operations

a. Select Setup Operations.

b. Enter Data Logging Period

c. If the alarm relay is being used please check

“Enable Alarm Relay Output”

d. Select the output sensor and set the Alarm trigger

point. The alarm will go off when the concentration

reaches above the concentration set for the

selected sensor.

e. Select the reset point of trigger. This is the

percentage of the alarm trigger concentration at

which the alarm will reset.

f. Select the alarm trigger point average period. This

signifies the time interval at which the average is calculated for control of the alarm.

Note: The alarm average period must be greater than or equal to the data report

rate

WWW.DUSTSENTRY.NL | +31 70 413 70 50

g. If the analogue output module is being used please select “Enable 4-20 mA module”.

The module will follow the “Output Sensor” selected.

Note 1: If “Active on diagnostic” is set the analogue output will go to full scale upon No Report

or Sensor Failure condition. If not selected the analogue output will remain in the state it was

in when the last valid reading was logged.

Note 2: When the zero calibration is taking place the analogue output module does not update,

i.e. it remains in the state it was in immediately prior to the zero calibration. The module

remains in this state until the zero calibration is finished, then updates on the next valid

reading.

h. If the modem is being used please select “Use Gatetel modem”. Once this has been

checked the option to enable email and SMS message alerts will appear. (Refer to

Section 3.3. for information on connecting and using the modem features)

10. Start data-logging to confirm sensor communication and operation is correct.

a. Click Data Table Real Time to launch real time data table.

b. Click File Start Data logging. Data will start being displayed in Real Time Table.

3.2. System Checks

The following are a list of checks that should be performed to ensure the communications are working

correctly and the data is being logged properly. If there is an issue with one of these checks please

refer to Section 4 or contact Aeroqual for technical support.

1. With the Dust Profiler on, open the door and observe the display on the controller. This should

be scrolling with sensor readings.

2. Connect a USB cable to the port on the Dust Profiler enclosure and connect to a PC running

the Dust Monitor PC software. Confirm that you can communicate correctly with the

instrument.

3. Verify the Dust Profiler is data logging correctly to the SD card by clicking “File Download

Files” on the PC software. A daily log file (DLYYMMDD.AQL) containing the DUST

PROFILER sensor data is created each day. Also system events such as power on,

configuration updates, calibration events and system faults are logged to an EVENTLOG.AQL

file.

4. Confirm that the Real Time Clock setting and Configuration is correct.

5. Confirm all of the sensors installed in the Dust Profiler are logging onto the SD card log files

and in the real time table in the PC software. If not check that all the sensors are loaded in

Configuration menu

3.3. Modem configuration

If the Gatetel GT-HE910_G Cellular Terminal is purchased with the Dust Profiler it will need to be

configured using the PC software. Firstly, the modem requires a suitable SIM card (not supplied) that

matches the configuration.

Note: The SIM card needs to be pushed into the modem with the electronic tile facing upwards.

WWW.DUSTSENTRY.NL | +31 70 413 70 50

Configure

Select Setup Configure GPRS Modem

Enter the SIM card provider’s APN and username and password if applicable

Note: To use the modem in Server Mode requires an unrestricted APN that can accept

connections

Click save

Select Operating mode and select one of the operating modes

If using Dyn Org service:

Dyn server name is: members.dyndns.org

Dyn login name is: your account log in name

Dyn login password is: your account log in password

DynDNS host name is: the name you have configured for this instrument

Note: You must reboot the Dust Profiler after saving the Dyn Org parameters.

The modem has the following operating modes:

1. TCP Client Mode:

IP and domain name support

Destination address and port

Dust Profiler connects to chosen server and data accessed via server.

Note: There is no remote access to the Dust Profiler using this mode, except via the

designated server.

2. TCP Server Mode:

DDNS support for fixed or dynamic public IP addresses (using dyndns.org)

Optional firewall to restrict which IP addresses can connect to Dust Profiler

Set TCP port

WWW.DUSTSENTRY.NL | +31 70 413 70 50

3.3.1. Further information about IP address solutions using GPRS Systems

GPRS is a communication technology that allows data acquisition systems to overcome the difficulty

of cabling for wide area remote sites. GPRS applications are becoming more prevalent, but the

dynamic IP address issues associated with GPRS networking continue to frustrate system integrators.

The trouble with I/O devices with GPRS capability is that they receive a different IP address every

time they connect to the GPRS network.

Three distinct solutions have been developed to overcome this challenge:

Solution 1: Public Static IP Address

The first option is to obtain a public static IP address; some carriers (telecom service providers) can

assign a static IP address to a specific SIM card. This way, all the I/O devices will have their own

static IP address. The main benefit of this solution is that it behaves like a wired solution. However,

not all carriers offer this kind of service.

Solution 2: VPN Service Provided by Carrier/MVNO

A VPN (Virtual Private Network) is a secure LAN solution that groups specific devices together. The

VPN grouping concept solves the dynamic IP address issues and prevents unauthorized persons

from accessing the data. For this VPN solution, customers are required to buy one of a number of

different GPRS on-line services to be able to access a Virtual Private Network (VPN). When the

GPRS device dials up, the carrier will assign a private IP address which is on the same network

segment as the host and can maintain bi-directional communication using a polling architecture. Many

enterprise clients turn to mobile virtual network operators (MVNO). These MVNO’s acquire numerous

GPRS services and then rents them out to customers who are looking for a small number of IP

addresses.

Unfortunately, some countries do not have MVNOs, and some carriers do not provide VPN services.

For this reason, this solution may be unfeasible for some users.

Aeroqual has used www.wyless.com successfully to communicate with AQM instruments.

Solution 3: DDNS

Using dynamic IP addresses is often necessary since many ISPs do not provide static IP addresses.

The Dynamic Domain Name System (DDNS) is used to convert a device’s name into a dynamic IP

address so that remote devices can communicate with the control centre using a fixed domain name.

DDNS takes care of the Dynamic IP address of a device, and DNS the static IP address of a device.

With most remote GPRS devices, you need to apply for a hostname for each of the devices handled

by the DDNS server. When GPRS devices get an IP address from the carrier, they will automatically

connect to the GPRS network. Each time a GPRS device’s built-in DDNS client gets a new IP

address, it will send the IP address to the DDNS sever.

Aeroqual has integrated the “DynDNS Pro” service from http://dyn.com with your GateTel

modem. For a small annual fee you can configure up to 30 host names to use with up to 30

modems.

3.3.2. Email Message

This function assumes the modem is fitted and correctly configured. It is activated by the “Enable

Email Alert” tick box under Operations. Up to 5 Email recipients can be connected at once.

WWW.DUSTSENTRY.NL | +31 70 413 70 50

Table of contents

Popular Measuring Instrument manuals by other brands

Bosch

Bosch GRL 250 HV Original instructions

Endress+Hauser

Endress+Hauser RID14 Brief operating instructions

APOELMOS

APOELMOS AP11-34 Series manual

Omega Engineering

Omega Engineering FMA-1600A Series user guide

Winters

Winters LCD11 Series Operation manual

Steinberg Systems

Steinberg Systems SBS-SM-130C user manual