Hütter Safety International

6

EN

TRAINING

lt is the responsibility of the users to assure that they are familiar with the instructions, and are trained in the correct care and use of this equipment. Users must also be

aware of the operating characteristics, application limits, and the consequences of improper use of this equipment.

INSPECTION

Frequency:

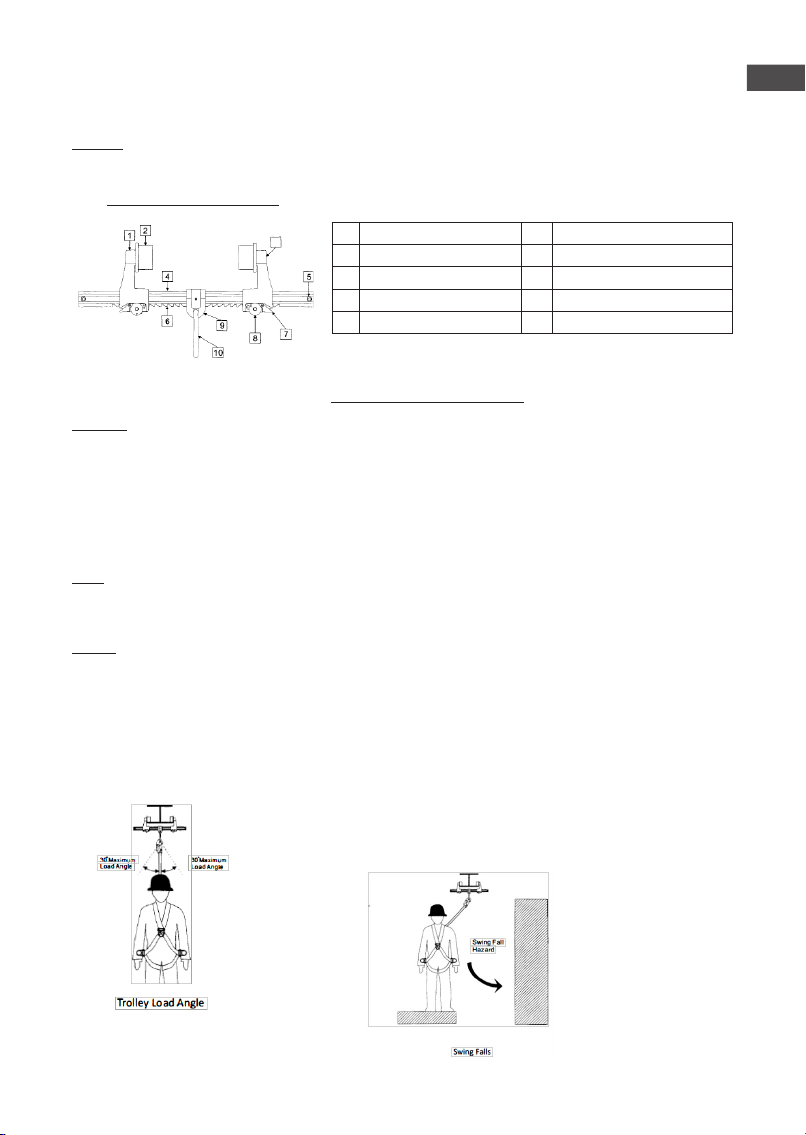

Before each use, inspect the Dual Beam Trolley Anchor according to following steps and see DUAL BEAM TROLLEY ANCHOR COMPONENTS for part identification. The Dual

Beam Trolley Anchor must be formally inspected by a competent person other than the user at least annually. Record the results in

INSPECTION AND MAINTENANCE LOG.

lnspection Steps:

Step 1.lnspect Dual Beam Trolley Anchor for damage: Look for cracks, dents, or deformities. Look for bending or wear on the hexagonal rod, trolley

clamps, safety loek, quick release loek pin, and trolley wheels. Ensure no parts are missing.

Step 2. lnspect entire unit for excessive corrosion.

Step 3. Ensure the quick release loek pin can be inserted through the hole on safety loek button, and locks in place.

Step 4. Record the inspection date and results in the INSPECTION AND MAINTENANCE LOG.

lf inspection reveals an unsafe or detective condition, remove the equipment from service and destroy, or return to Hütter Safety for repair.

NOTE: Only Hütter Safety or porties authorized in writing are qualified to repair this equipment.

MAINTENANCE, SERVICE, STORAGE

Cleaning:

Periodically clean the Dual Beam Trolley Anchor by water and a mild soap solution. Do not use acids or other caustic chemicals that could damage the system components.

A lubricant may be applied to the safety loek button and the quick release lock pin.

Storage:

Store the equipment in a cool, dry, dark place, chemically neutra 1, away from sharp corners, sources of heat, humidity, corrosive substances or other damaging conditions.

VERIFICATION PROCEDURE:

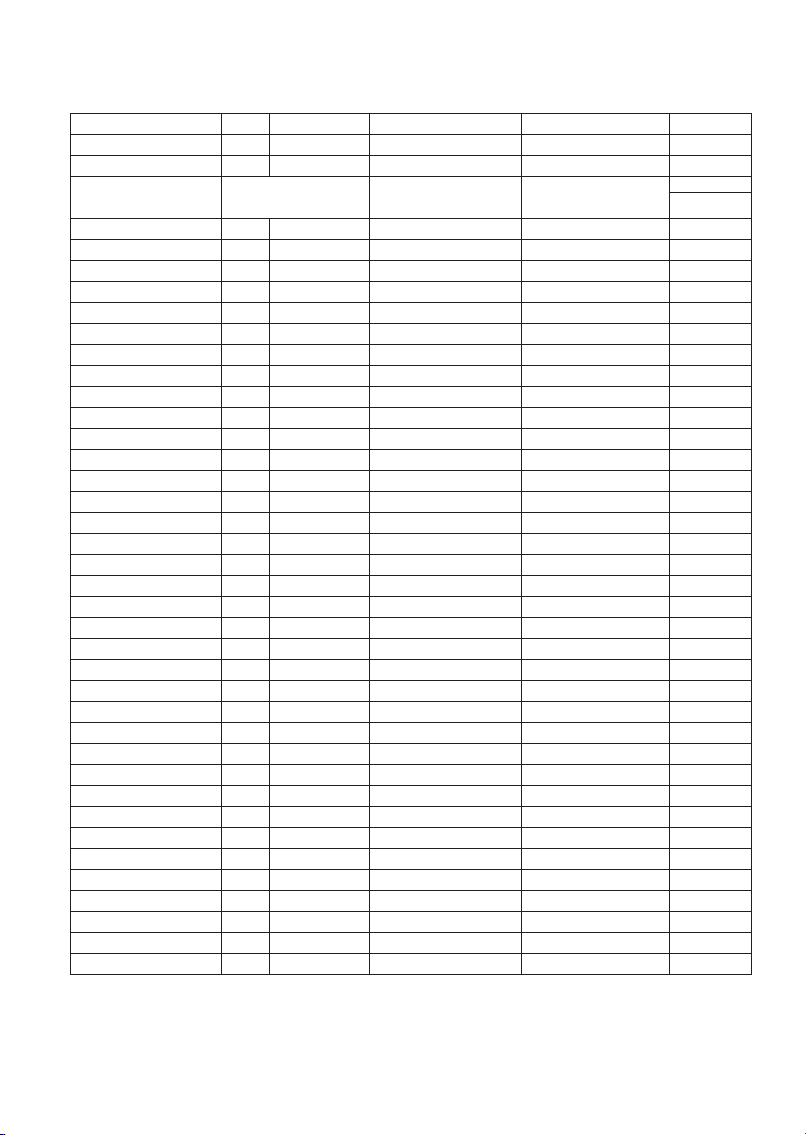

Service life of the product is 10 years (in accordance with the annual examination by a competent person authorized by Hütter Safety),

although its actual service life may be longer or shorter, depending on its usage and/or annual inspection results.

Hütter Safety or his authorised representative must systematically check the beam anchor in case of doubt or after a fall and at least every

year by, to guarantee its state and thus the safety of the end-user.

The product data sheet should be completed after each annual product verification.

SERVICING AND STORAGE: (Comply strictly with these instructions)

During transport, keep the beam anchor in its packaging, away from any cutting surface. Wipe it with a rag and place it in a well-ventilated location, let

it dry naturally and keep it away from a flame or heat source. The beam anchor should be stored in its packaging in a warm, dry, ventilated place, away

from chemicals.

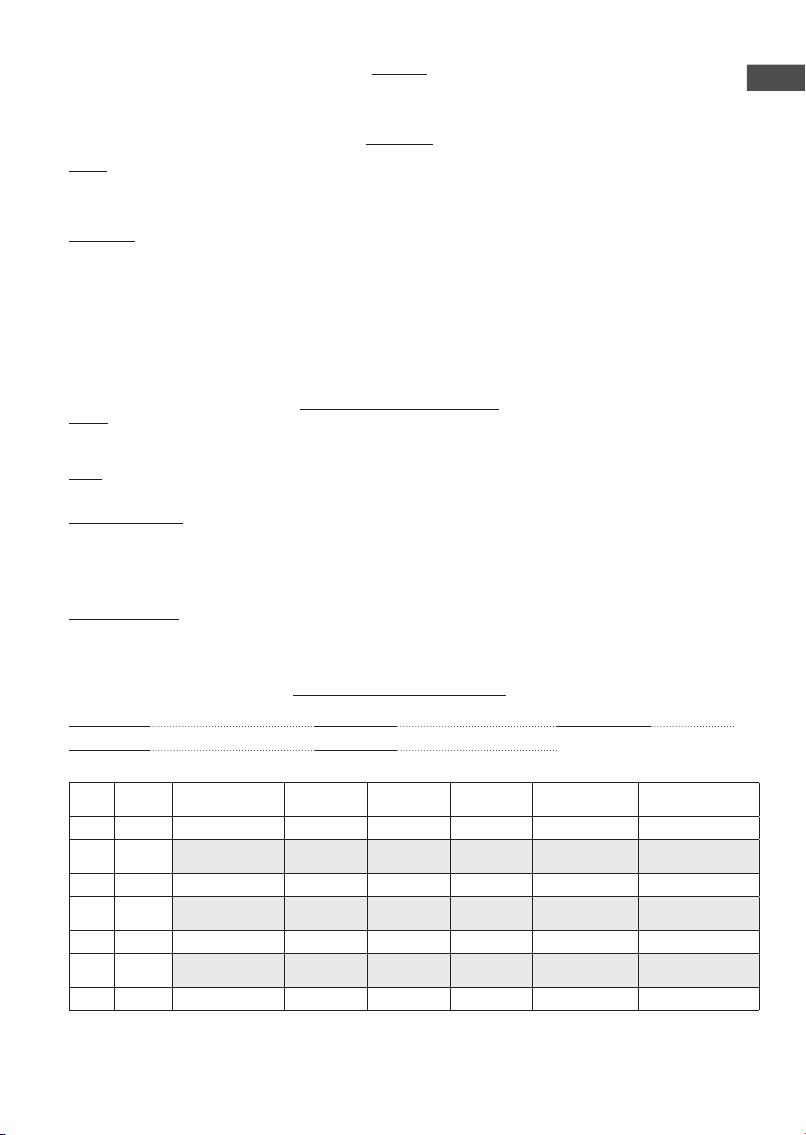

INSPECTION AND MAINTENANCE LOG

Company: Location : Date Purchased:

Serial Noº : Model Noº :

Year Date By a Qualified Person No missing parts No corrosion No Deformation Functioning condition No changes to

Attachment structure

Corrective Action Maintenance

Performed

Corrective Action Maintenance

Performed

Corrective Action Maintenance

Performed