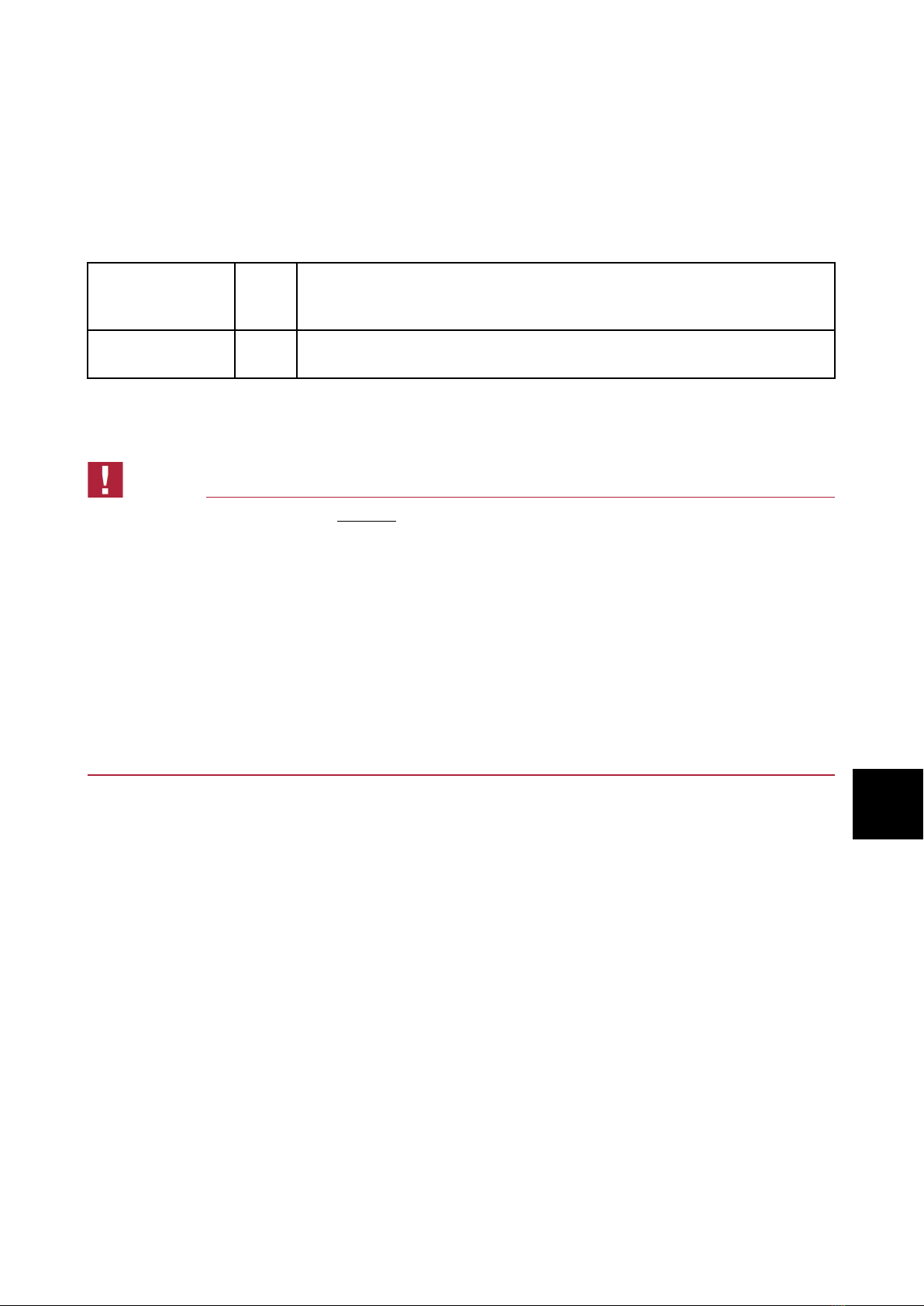

Contents

GB

Contents

1. General information ................................................................................................................... 1

2. General safety information....................................................................................................... 1

3. Electrical connection ................................................................................................................. 2

4. Chimney ........................................................................................................................................ 2

4.1. Weather conditions.................................................................................................................... 3

4.2. Chimney flue draft at rated heat output of the stove............................................................. 3

4.3. Connection to the chimney....................................................................................................... 3

4.3.1. Multiple use ............................................................................................................................. 3

4.3.2. Connection to the existing chimney (example) .................................................................. 3

5. Installation .................................................................................................................................... 4

5.1. Minimum gaps to flammable components ............................................................................. 5

5.2. Combustion air supply............................................................................................................... 5

5.3. Operation of the stove depending on the air from the room:............................................... 6

5.3.1. Operation of the stove independent of the air from the room (RLU):.............................. 6

5.4. Outside air connection .............................................................................................................. 6

5.4.1. Outside air connection (RLU) ............................................................................................... 7

5.5. Convection air distribution – Double Air ................................................................................. 7

5.6. Room temperature sensor........................................................................................................ 8

6. Operator console functions ..................................................................................................... 9

6.1. Symbols on the display ............................................................................................................. 9

7. Operating the pellet stov........................................................................................................... 9

7.1. Suitable fuels .............................................................................................................................. 9

7.2. Unsuitable fuels.......................................................................................................................... 9

7.3. Using for the first time ............................................................................................................... 9

7.3.1. General: ................................................................................................................................... 9

7.3.2. Operating console: ............................................................................................................... 10

8. Additional operator console functions ............................................................................... 12

8.1. Backlighting .............................................................................................................................. 12

8.2. Energy saving mode - Actual room temperature display ................................................... 13

8.3. Button lock (child safety device) ............................................................................................ 13

9. Functions in the main menu................................................................................................... 13

9.1. Main menu – Select functions ................................................................................................ 13

9.1.1. Manual operating mode....................................................................................................... 14

9.1.2. Automatic operating mode .................................................................................................. 15

9.1.3. Operating mode Weekly program ...................................................................................... 15

9.1.4. Heating curve ........................................................................................................................ 17

9.1.5. ECO Mode............................................................................................................................. 17

9.1.6. Maintenance.......................................................................................................................... 17

9.1.7. Power stage blower.............................................................................................................. 18

9.1.8. Date / Time ............................................................................................................................ 18

9.1.9. Display ................................................................................................................................... 18

9.1.10. Network................................................................................................................................ 18

9.1.11. Error Log .............................................................................................................................. 20

9.1.12. Manual filling (for HSP 4.0-F2 only)................................................................................. 20

9.1.13. Info Software ....................................................................................................................... 21

9.1.14. Language............................................................................................................................. 21

10. Mobile application - general safety instructions ............................................................ 21

10.1. Installation of mobile application ......................................................................................... 21

10.2. Range of functions................................................................................................................. 22

10.3. Function description - Network modes ............................................................................... 22

11. Oper. modes ............................................................................................................................. 23