Congratulations! You are the owner of a HAAS + SOHN

pellet stove, a quality product. Please read through

these instructions carefully. They will tell you all about

the functions and operation of this stove, which will

increase the utility of this device and extend its working

life. What is more, with the correct heating you can save

fuel and protect the environment.

We can only give a guarantee on our products if you

observe the following instructions in these installation

and operating instructions. In addition, the stove must be

correctly installed so as to prevent possible accidents.

Look after these instructions well, then you will be able

to familiarise yourself with the correct operation of your

stove at the start of every heating period.

Note:

The installation and operating instructions given in this

manual may differ entirely or in part from public authority

instructions. In that event, the public authority

instructions always apply! The drawings in these

instructions are not to scale and serve only as

illustrations.

1. Description

Pellet stoves are particularly suitable for the constant

heating of residential and work rooms. The

HAAS+SOHN pellet stove is set up to operate in fully

automatic mode, with a choice of 2 operating modes

(“Heating” and “Auto”with a weekly programme).

Depending on the room temperature and on the model,

a volume of fuel for a maximum of 30 hours of constant

operation may be stored in the built-in storage container.

The fuel is fed automatically from the pellet tank to the

grate via a screw conveyor, with the quantity of fuel

automatically being adjusted to the relevant heat output.

The internal control unit regulates the ignition phase, the

heating phase and the cooling down phase, thereby

guaranteeing safe operation of the pellet stove. The

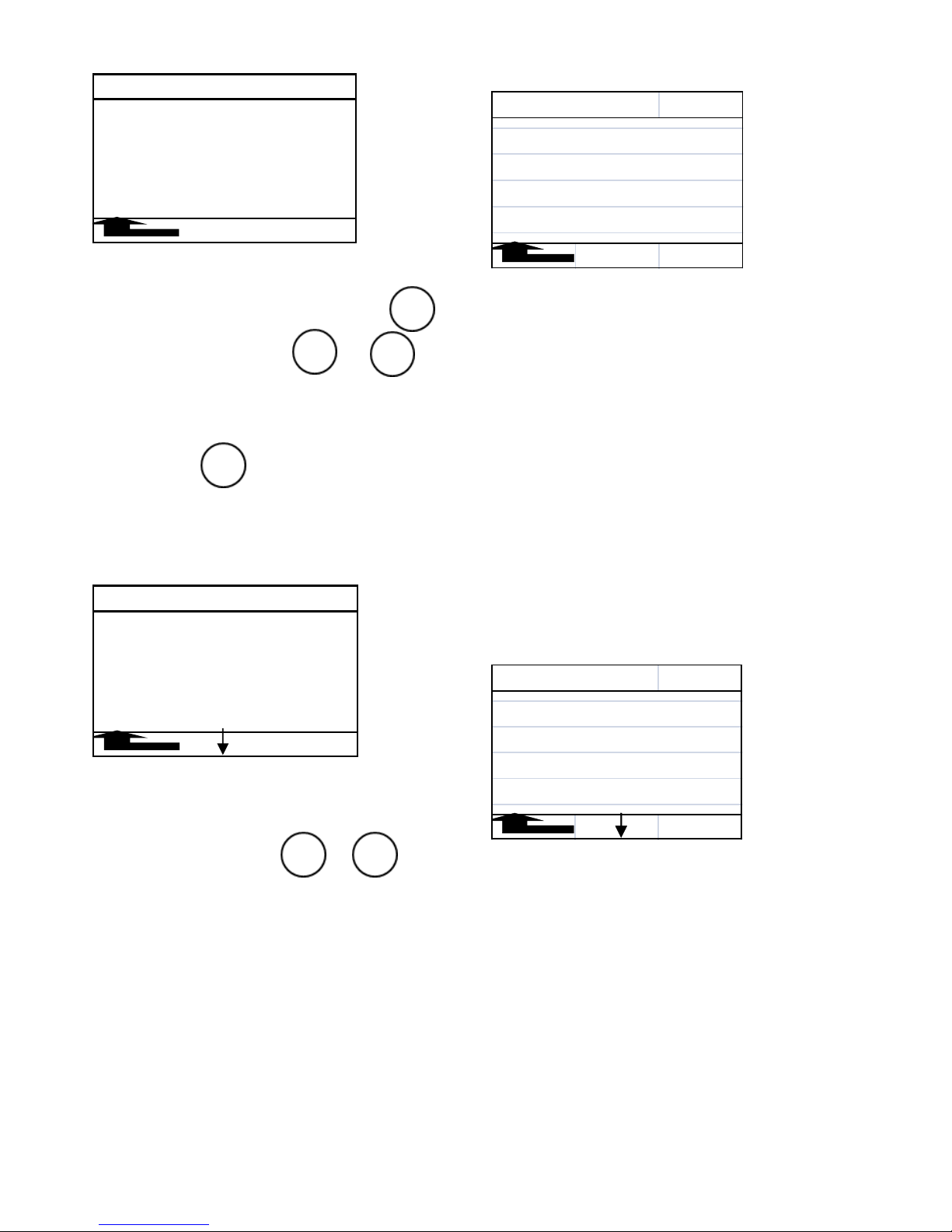

operator console, which consists of a display and four

function keys, is built into the pellet tank cover.

The heating of the air in the room and the creation of

comfortable living conditions is mainly achieved by

convection. This allows you to quickly warm up even

cold rooms that have been unheated for a lengthy

period. The cooler air of the room enters the stove at the

bottom of the cladding, is heated and flows out again at

the top in the area of the slats. The proportion of radiant

heat is given off by radiation in the area of the viewing

window of the combustion chamber door and from the

stove’s metal surfaces.

2. General instructions, safety instructions

Before commissioning the pellet stove read the

entire installation and operating instructions through

thoroughly.

Only permitted handling gear with sufficient

loadbearing capacity may be used for moving your

device.

Your heating device is not suitable for use as a

ladder or mounting frame.

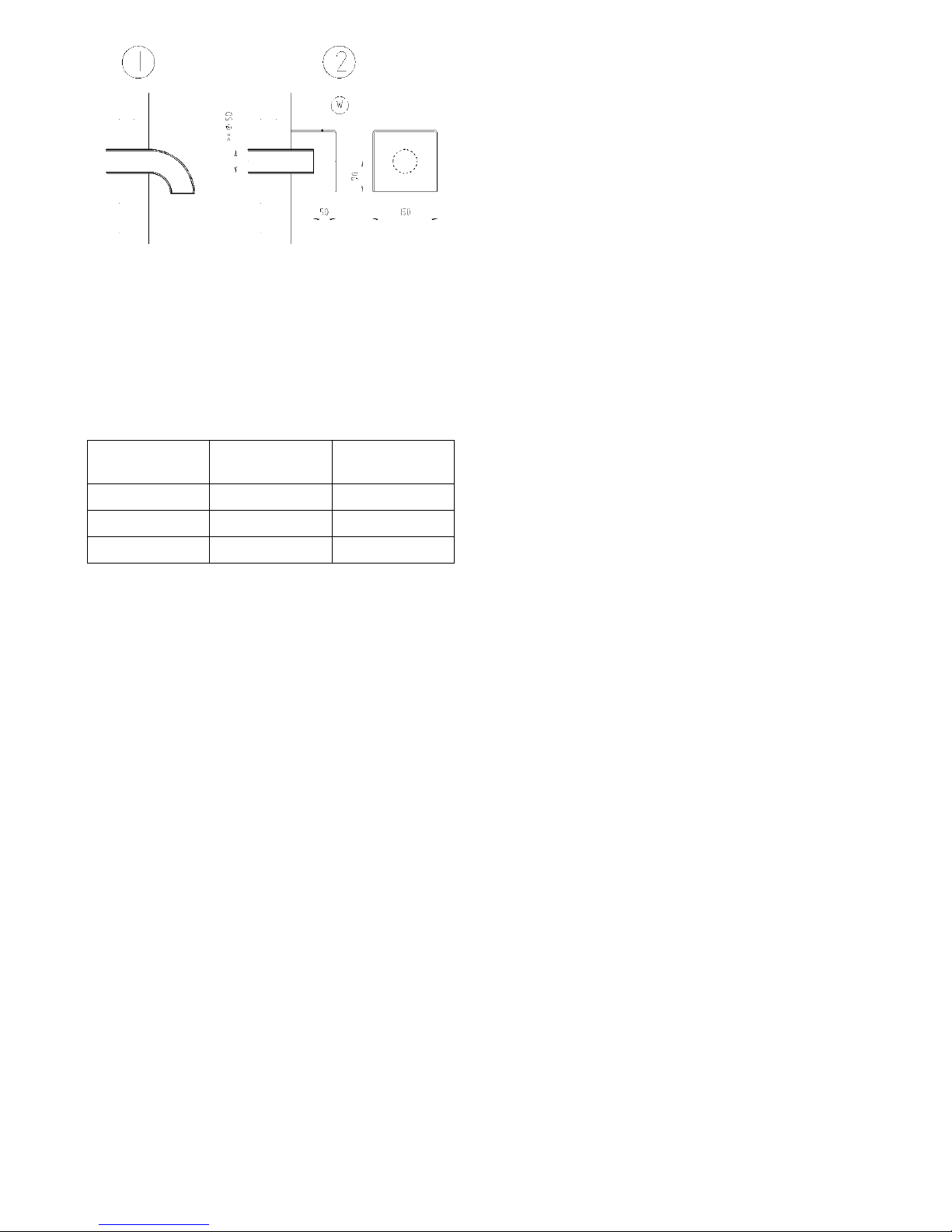

For the installation of your stove, the fire protection

authority’s regulations and the local building

regulations in force at the installation site are to be

observed and you should also discuss this with the

district heating inspector. He will also check that the

connection of the device to the fireplace is carried

out correctly.

All the checks required by law have been performed

on your stove. The mandatory indices regarding

technical combustion efficiency and flue gas

emissions are observed.

The pellet stove may not be connected to a multiple-

use chimney provided. The supply pressure must

be at least 6 Pa and should be 15 Pa as a

maximum.

The combustion chamber door may be opened only

for cleaning and maintenance during operating

status “Off”. Otherwise it is to be kept closed –even

when the stove is not operating in order to avoid

affecting other heating appliances and the

associated risks.

An adequate supply of fresh air must be guaranteed

to the room where the stove is installed. However,

the pellet stove offers you the option of a direct

connection to the outside air via a suitable air duct.

So operation independent of the air in the room is

possible. (See Section 3 “Installation of the pellet

stove and connection to the chimney”).

Attention! The pellet stove may not be set

up to be operated jointly with the home’s air

conditioning and ventilation units.

The chimney (fireplace or flue) must be made of

stainless steel or ceramics (glazed internally) and

suitable for wet operation so that it cannot rot.

The pellet stove cannot be connected to the mains

electricity until it has been correctly connected to the

fireplace.