HABCO® TECHNICAL DOCUMENT - C098791 • 10310209

© HABCO Manufacturing Inc. “HABCO, Cassette, Cold Space Merchandiser” are registered trademarks of HABCO Manufacturing Inc. Domestic and International Patents. Page 4

HABCO® Commercial Refrigerators, Powered by Cassee®, are designed

and engineered to the highest standards using only quality components

for years of reliable service. Any use of the product for purposes other

than which it was designed, will void any and all manufacturer’s war-

ranty, stated or implied.

A. INSPECTION & UNPACKING

1. A thorough inspecon of the appliance should be made prior

to formally receiving the goods from the carrier. If there are any

markings (ie. scus, dents, scratches) of the packaging, please note

this on the carrier’s delivery slip and have driver sign your copy

acknowledging damage. Common pracce will have the carrier re-

port your concerns before leaving the premises.

2. Advise your carrier, or HABCO (if shipped via our transport) of any

damage immediately, nong the following items.

3. Retain all packaging and forward HABCO a copy of the Delivery Slip

signed by carrier acknowledging damage, Serial Number of Unit,

and digital photos of area damaged and packaging next to locaon

of damage.

4. Once the appliance has been received in good condion, remove

stretch-wrap, corners protectors and bag.

WARNING: RISK OF SUFFOCATION! KEEP PLASTIC PACKAGING MATERIAL

AWAY FROM CHILDREN AND ANIMALS, AND DISPOSE SAFE AND SECURE.

5. Shipping Plaorm Removal:

WARNING: RISK OF PERSONAL INJURY! EMPLOY BEST HEALTH AND SAFETY

LIFTING PRACTICES WHEN REMOVING SHIPPING PLATFORM(S); LEVELING

CABINET; REVERSING DOORS; AND MOVING APPLIANCE. IF IN DOUBT, ASK

FOR HELP.

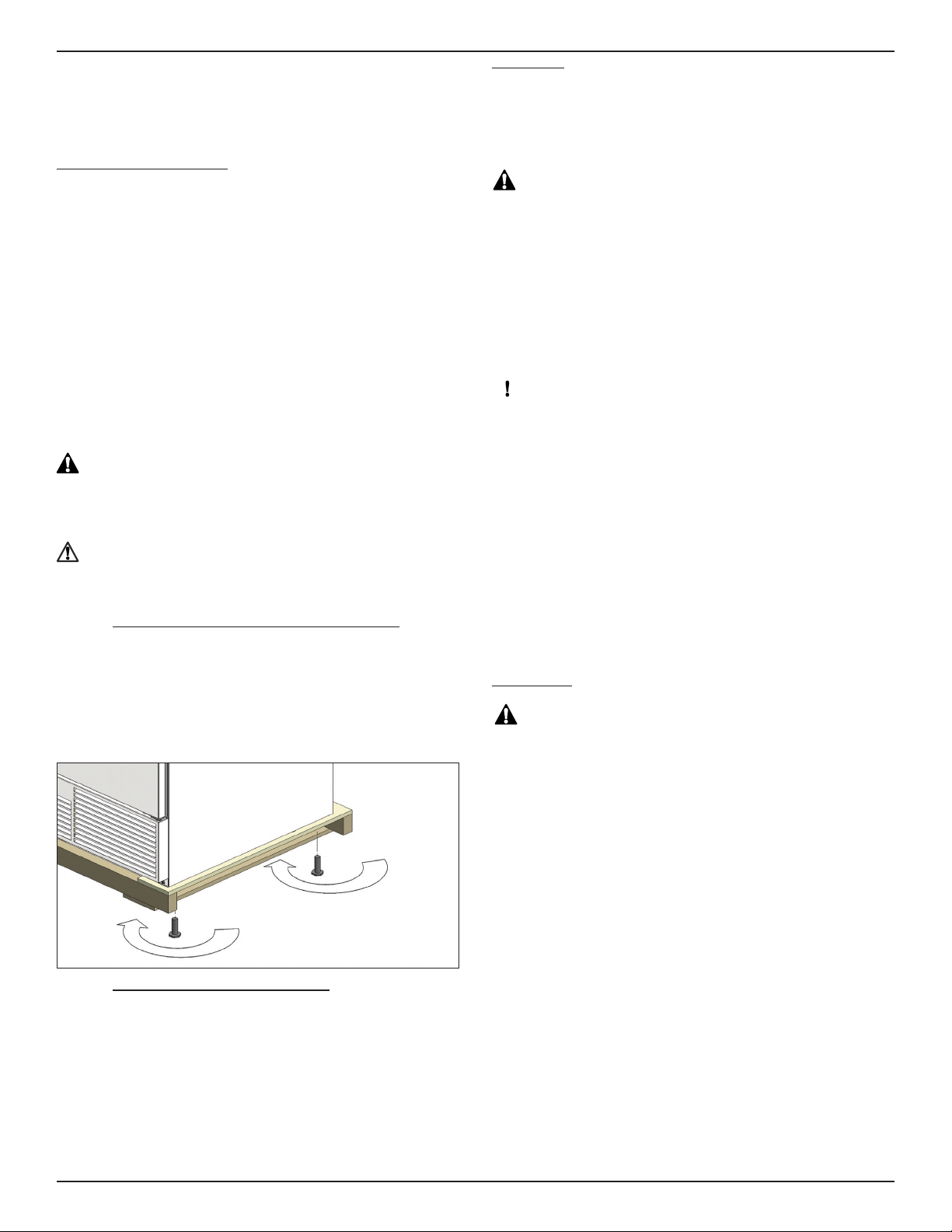

Shipping Pallet - Commercial Refrigeraon - FIG A1

a. HABCO® Foodservice and Commercial appliances are shipped

on pallets. Pallets are fastened with the appliance leg levelers.

Insets on each side of skid are provided to allow easy access

for 1-3/8” wrench or socket to remove the levelers and skid

respecvely. Once pallet is removed, reinstall levelers and

level cabinet front to back and side to side.

FIG. A1

b. CASTER KIT INSTALLATION - OPTIONAL

HABCO® Commercial Refrigerators may be equipped with an

optional caster kit. To install caster kit, follow these proce-

dures:

i. Install non-braking casters at rear of the refrigerator by

threading into existing leg leveler hole.

ii. Install braking casters at front of the refrigerator by threading

into existing leg leveler hole. WHEN ROLLING REFRIGERATOR

INTO POSITION, ENSURE THE FRONT CASTERS EXTEND OUT-

WARD FROM THE CABINET FACE.

iii. When in place, engage brakes on front casters.

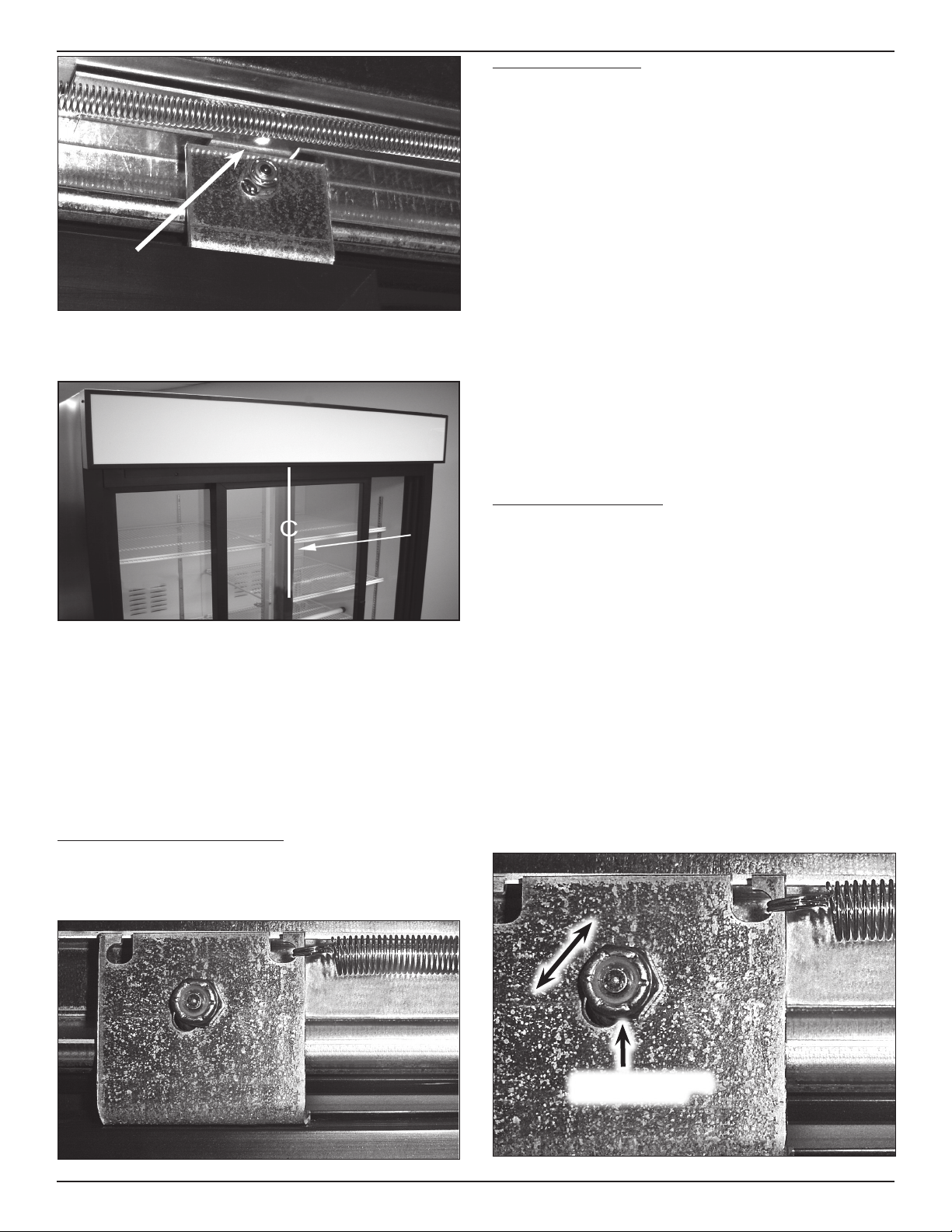

B. LOCATION

1. Posion appliance on level oor. The appliance MUST be level,

otherwise door(s) may not close and condensate may not drain

property.

2. Allow 1” (2.54 cm) clearance at rear of appliance for power cord.

WARNING: RISK OF FIRE, AND ELECTROCUTION!

DO NOT ALTER, IMPACT OR PLACE PRESSURE ON POWER CORD. AL

LOW ADEQUATE SPACE FOR POWER CORD TO FLOAT FREELY BETWEEN

CABINET AND WALL AND DO NOT STRAIN AND/OR STRETCH POWER

CORD TO REACH ELECTRICAL RECEPTACLE.

DO NOT INSTALL OUTDOORS AND/OR IN DAMP CONDITIONS.

DO NOT INSTALL APPLIANCE WHERE STORAGE, HANDLING AND/OR DIS-

PENSING FLAMMABLE AND/OR EXPLOSIVE MATERIALS OCCUR.

3. Appliance must be posioned with front grill unobstructed.

NOTICE: RISK OF APPLIANCE DAMAGE!

DO NOT OBSTRUCT AIR-RETURN GRILLS LOCATED INSIDE CABINET NEAR

THE LOWER LEFT AND RIGHT OF THE REAR AIR DISTRIBUTION PANEL. DO

NOT BLOCK EXTERIOR, LOWER FRONT GRILL. FAILURE TO COMPLY MAY

RESULT IN RESTRICTED AIR CIRCULATION, SUBSTANTIALLY REDUCED COOL-

ING PERFORMANCE AND DAMAGE TO REFRIGERATION COMPONENTS

AND VOID WARRANTY.

DO NOT LOCATE APPLIANCE IN DIRECT SUNLIGHT OR IN CLOSE PROXIM-

ITY TO HIGH HEAT OR HIGH HUMIDITY SUCH AS FRYERS, RANGES, DISH-

WASHRS, STEAM COOKERS AND/OR HEATING DUCTS

DO NOT INSTALL DIRECTLY BENEATH UNDIFFUSED AIR CONDITION

ING VENTS.

DO NOT INSTALL OUTDOORS, IN DIRECT SUN, DAMP, EXTREME HEAT

AND/OR COLD CONDITIONS.

C. ELECTRICAL

WARNING: RISK OF DEATH, FIRE, EXPLOSION, ELECTRICAL SHOCK AND/OR

OTHER PERSONAL INJURY!

PLUG INTO A DEDICATED, 3 PRONG GROUNDED ELECTRICAL RECEP

TACLE AND DO NOT USE EXTENSION CORDS, POWER BARS, AND/OR

ADAPTERS TO POWER THIS APPLIANCE. IF IN DOUBT, EMPLOY A CERTI-

FIED ELECTRICIAN TO CONFIRM YOUR POWER SUPPLY MEETS CRITERIA.

DO NOT ALTER, IMPACT OR PLACE PRESSURE ON POWER CORD. AL

LOW ADEQUATE SPACE FOR POWER CORD TO FLOAT FREELY BETWEEN

CABINET AND WALL AND DO NOT STRAIN AND/OR STRETCH POWER

CORD TO REACH ELECTRICAL RECEPTACLE.

INSPECT POWER CORD FOR ANY DAMAGE PRIOR TO POWERING AND

WHENEVER HABCO® CASSETTE® IS EXCHANGED OR APPLIANCE IS MOVED.

DO NOT PLUG THIS APPLIANCE INTO WALL RECEPTACLE IF POWER

CORD IS DAMAGED.

DO NOT ACCESS MECHANICALLY FASTENED AREAS WITHOUT PERMIS

SION OF OWNER AND READING AND UNDERSTANDING PRODUCT

MANUAL.

DISCONNECT POWER BEFORE ACCESSING MECHANICALLY FASTENED

AREAS.

1. Check that the power supply conforms to the data plate located on

the upper le interior wall of the cabinet.